- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ABOUT US

Cast Diamond Quality, Create a Beautiful Life!

Shijiazhuang Casiting Trading Company is a professional supplier which is specialized in various kinds of castings. We can produce and provide various kinds of steel castings, ductile/gray iron castings, aluminum castings with product unit weight from a few kilograms to 10000 kilograms.

Our factory covers an area of more than 50000 square meters, and the total production capacity of various castings exceeds 20,000 tons/year, It is a leading enterprise in the production of coal mine machinery castings in China. We have more than 500 employees including various casting engineers, technicians, senior skilled technical workers, and administrative staff. We have two auto molding lines: one is the VRH molding production line, and another one is the resin sand production molding line. The casting process adopts a computer simulation software system, which can simulate the casting process quickly, accurately, and comprehensively. The smelting equipment includes electric arc furnace, intermediate frequency furnace, and LF refining furnace. The heat treatment equipment includes desktop resistance and gas furnaces, all controlled by an automatic program. We also have lost foam casting equipment and a 205 kg cast steel new material test furnace, which can realize the test to large-scale production of castings of various materials.

Our factory has complete and self-contained inspection equipment. The on-site inspection is equipped with a vacuum direct-reading emission spectrum analyzer, a three-coordinate measuring inspector, a large wet magnetic particle detector, an ultrasonic flaw detector, and a color penetrating flaw detector. With a full-featured molding sand laboratory and testing center, we can achieve strict quality control in all aspects from raw materials, and production processes to final products.

Driven by the concept of green and clean products as our factory’s development direction, we established a high-quality, high-efficiency, low-consumption, clean, flexible casting system, using easily renewable and recyclable casting materials and casting processes. The advanced frequency conversion dust removal system protects the health of the foundry industry and greatly reduces the pollution of the casting to the environment. Our factory is a domestic "first-class environmentally friendly green casting enterprise" and a "China Green Casting Demonstration Enterprise" designated by the China Foundry Association.

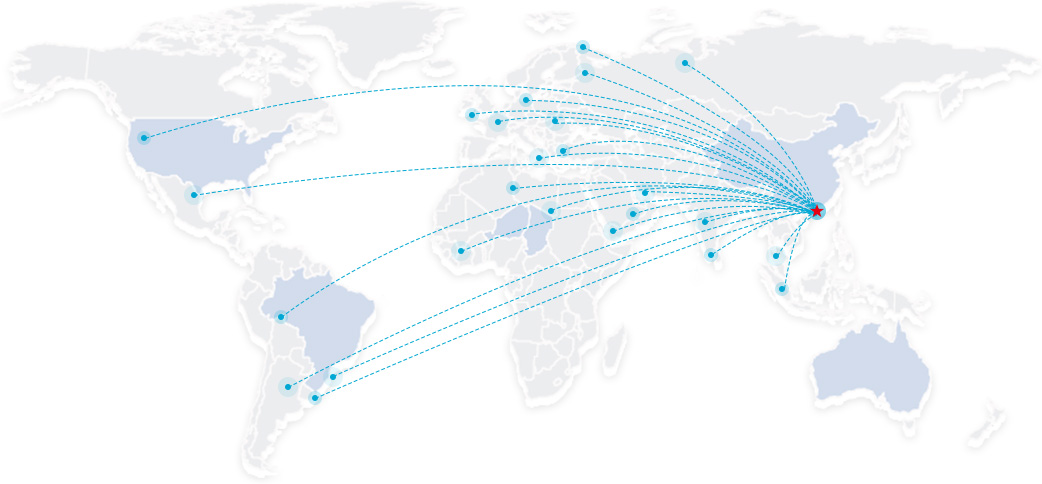

Our various casting products have been exported to many countries and regions in the world such as the United States, Britain, Vietnam, Bangladesh, Australia, Turkey, and so on.

We are looking forward to cooperating with new and old customers for a win-win situation!

-

40+Branch offices

-

500+Global distributors

-

100+Global countries