ታኅሣ . 02, 2024 00:43 Back to list

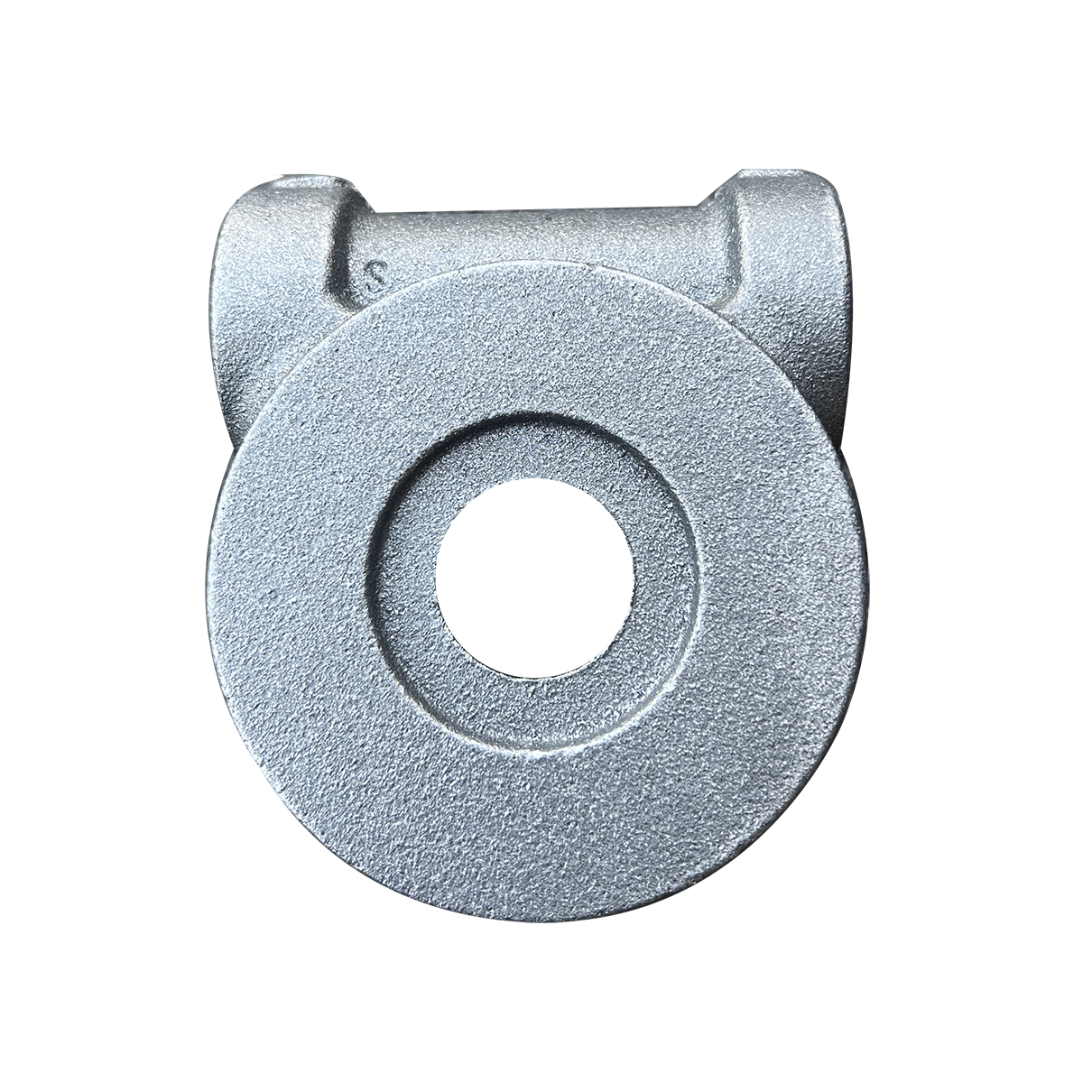

Custom Ductile Iron Pipe Mold with Bottom Ring Design and Manufacturing Solutions

The Importance of OEM Ductile Iron Pipe Mould Bottom Ring in Modern Infrastructure

In the realm of modern infrastructure, the materials used for construction play a critical role in ensuring durability, strength, and reliability. Among these materials, ductile iron has emerged as a preferred choice for manufacturing various components, notably pipes. The OEM (Original Equipment Manufacturer) ductile iron pipe mould bottom ring is a vital component in this sector, serving various functions that contribute to the overall performance of piping systems.

The Importance of OEM Ductile Iron Pipe Mould Bottom Ring in Modern Infrastructure

The OEM mould bottom ring plays a pivotal role in the casting process of ductile iron pipes. This component serves as the foundation for the pipe during the casting operation. It helps to create the required shape and dimensions while providing support to the molten iron as it is poured into the mould. The bottom ring is expertly designed to withstand high temperatures and pressures, ensuring that the casting process is stable and efficient. A well-fabricated bottom ring contributes to the formation of uniform wall thickness in the pipes, which is crucial for their structural integrity.

oem ductile iron pipe mould bottom ring

Moreover, the bottom ring aids in the cooling and solidification of the cast iron. Proper cooling ensures that the ductile iron crystallizes correctly, which is essential for imparting the desired ductility and strength. Any defects or irregularities at this stage of production could lead to compromised pipe quality, resulting in costly repairs and delays. Therefore, the OEM mould bottom ring must meet strict quality standards, as its performance directly influences the manufacturing outcome.

The role of OEM ductile iron pipe mould bottom rings is not limited to their correctness in casting; their design must also reflect a customer-centric approach. This means considerations such as ease of use, compatibility with existing machinery, and cost-effectiveness during production must be taken into account. As manufacturers strive to optimize their processes and reduce costs, the importance of high-quality mould bottom rings cannot be overstated. They must be manufactured using advanced techniques and materials that guarantee longevity and reliability.

Another significant aspect of OEM ductile iron pipe mould bottom rings is their contribution to sustainability in infrastructure. The durability of ductile iron pipes extends their lifecycle, leading to reduced maintenance and replacement costs over time. Furthermore, manufacturers committed to sustainability seek to use recycled materials in producing ductile iron components, aligning with global efforts to minimize environmental impact.

In conclusion, the OEM ductile iron pipe mould bottom ring is a fundamental component in the production of high-quality ductile iron pipes. Its importance lies not only in its structural function during manufacturing but also in its implications for the quality and longevity of the final product. As infrastructure demands continue to grow, the role of precision-engineered components like the mould bottom ring will remain crucial in ensuring that ductile iron pipes meet the rigorous standards of modern applications. Investing in high-quality mould bottom rings is, therefore, an investment in the durability, efficiency, and sustainability of infrastructure projects worldwide.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025