ታኅሣ . 01, 2024 16:54 Back to list

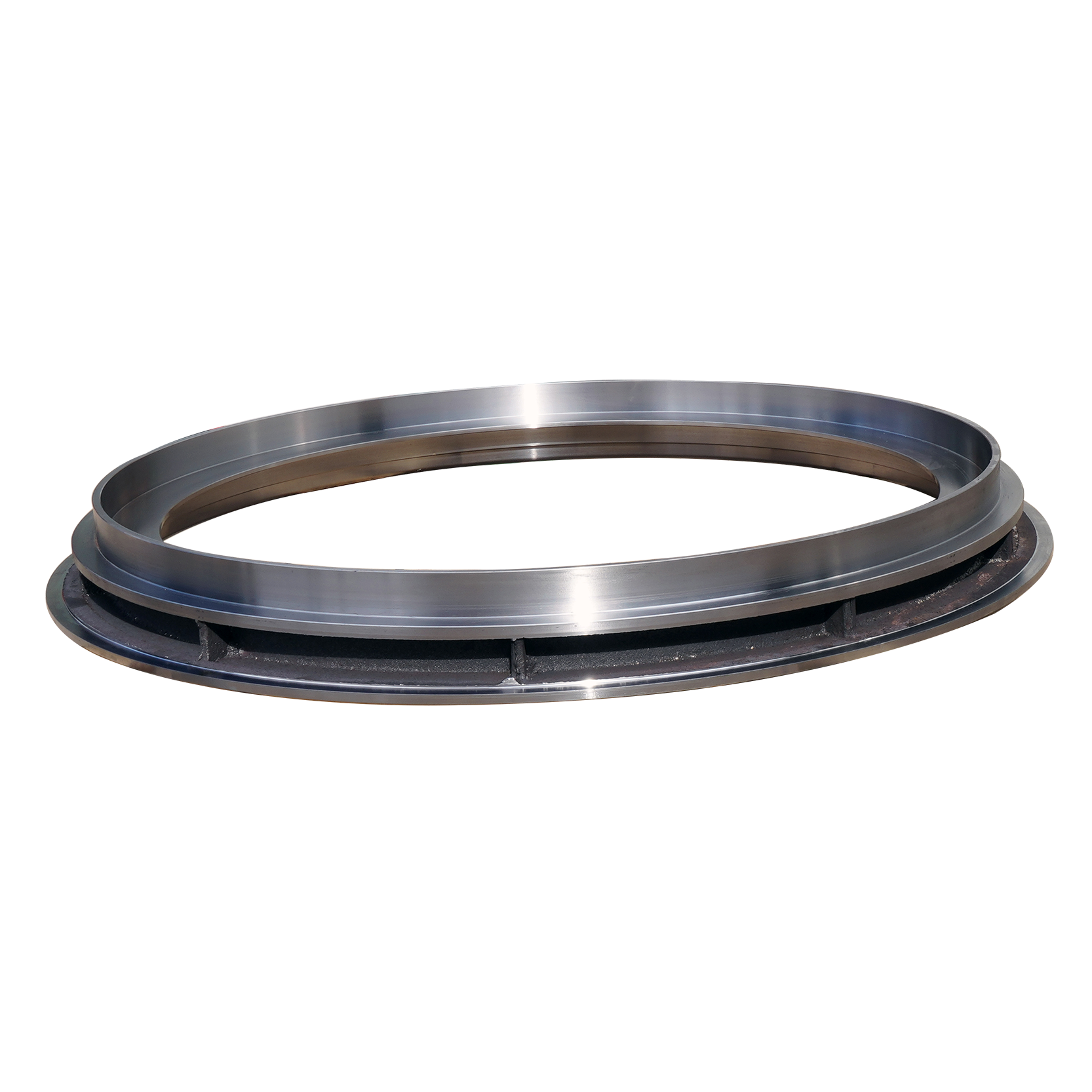

panel heat exchanger

Understanding Panel Heat Exchangers An Overview

Heat exchangers play a crucial role in various industrial and commercial applications, and among them, panel heat exchangers have emerged as a popular choice due to their efficiency and flexibility. In this article, we will explore the concept of panel heat exchangers, their design, applications, and advantages, providing a comprehensive overview for those interested in this vital technology.

What is a Panel Heat Exchanger?

A panel heat exchanger is a type of heat exchanger that uses a series of plates or panels to transfer heat between two or more fluids. These panels are typically made of conductive materials, allowing for efficient heat transfer while maintaining physical separation between the fluids. Unlike traditional shell-and-tube heat exchangers, which can be bulky and complex, panel heat exchangers are often more compact, making them suitable for a variety of settings including HVAC systems, industrial processes, and power plants.

Design and Construction

The design of a panel heat exchanger involves the arrangement of multiple thin plates stacked together to create space for the fluids. The design allows for a large surface area relative to volume, which significantly enhances heat transfer efficiency. The plates usually have a corrugated or ribbed surface to increase turbulence, promoting better heat exchange.

The materials used in construction can vary based on the application and the fluids involved. Common materials include stainless steel, titanium, and carbon steel, chosen for their thermal conductivity and corrosion resistance. The configuration of the panels can also be customized to meet specific performance requirements, adapting to different flow rates and temperature ranges.

Applications

Panel heat exchangers are versatile and can be found in a wide range of applications. Some of the most common areas include

2. Food and Beverage Industry These heat exchangers are used for pasteurization processes, where precise temperature control is essential to ensure food safety while maintaining product quality.

panel heat exchanger

3. Chemical Processing In the chemical industry, panel heat exchangers are employed for cooling and heating chemical reactions, allowing for close temperature control without contamination.

4. Renewable Energy Systems In solar energy applications, panel heat exchangers play a vital role in transferring heat from solar collectors to storage tanks, enhancing energy efficiency.

Advantages of Panel Heat Exchangers

Panel heat exchangers offer several advantages compared to traditional heat exchangers

1. Compact Size Their design allows for a smaller footprint, making them easier to install in tight spaces while still delivering high performance.

2. High Efficiency Due to the increased surface area and improved flow patterns, panel heat exchangers can achieve higher thermal efficiency, reducing energy consumption.

3. Easy Maintenance Many designs allow for easy disassembly, making cleaning and maintenance straightforward, which is essential for industries requiring hygiene and low downtime.

4. Customizability Panel heat exchangers can be tailored to specific requirements, accommodating various fluids, pressures, and temperatures, thus providing flexibility in their use.

5. Cost-Effectiveness Though initial costs may vary, the operational savings due to their efficiency and reduced maintenance contribute to a lower total cost of ownership over time.

Conclusion

Panel heat exchangers represent an efficient and adaptable solution for thermal management in various industries. Their compact design, high efficiency, and ease of maintenance make them a preferred choice in modern applications, from HVAC systems to food processing. As technology continues to evolve, the role of panel heat exchangers in enhancing energy efficiency and operational effectiveness will likely expand, contributing to sustainable practices across various sectors. Understanding their functionality and advantages equips businesses and engineers to make informed choices in heat transfer applications.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025