ታኅሣ . 05, 2024 06:29 Back to list

Manufacturer of Steel Reinforced Concrete Pipe Mould Bottom Rings for Optimal Durability

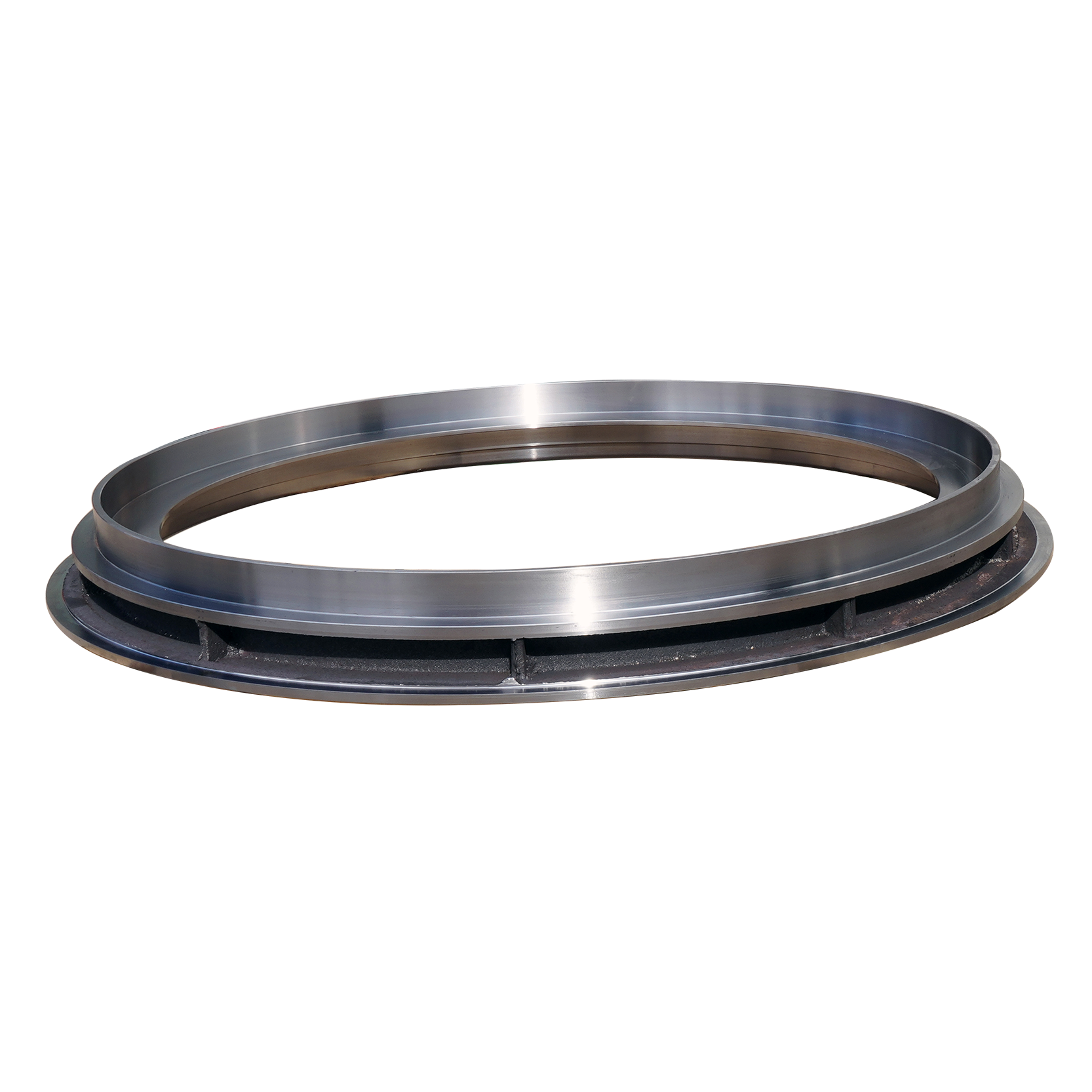

Understanding Steel Reinforced Concrete Pipe Mould Bottom Ring Manufacturing

The construction industry continually seeks innovative materials and solutions to enhance structural integrity while keeping costs manageable. A key component gaining attention is the steel reinforced concrete pipe (SRCP), which benefits from the strength of both steel and concrete. One critical part of the manufacturing process for SRCP involves the bottom ring of the mould, a component that plays a pivotal role in ensuring the overall quality and performance of the pipes produced. This article delves into the intricacies of the manufacturing process for steel reinforced concrete pipe mould bottom rings, highlighting their significance, production techniques, and advantages.

Significance of the Bottom Ring

The bottom ring of the mould is critical in shaping the concrete pipes during the curing process. It bears the weight of the concrete mixture and supports the mould structure to maintain its integrity under pressure. A well-manufactured bottom ring ensures that the pipes produced have consistent dimensions and superior durability, making it a vital component in the production of high-quality SRCPs.

Moreover, the bottom ring influences the overall structural performance of the pipes. Given that SRCPs are often used in infrastructure applications like sewer systems, storm drainages, and culverts, it is crucial that these pipes maintain their structural integrity under various loading conditions. Therefore, the bottom ring must be designed and manufactured with precision to withstand significant stress.

Manufacturing Process

The manufacturing of steel reinforced concrete pipe mould bottom rings involves several key steps, each integral to ensuring the final product meets industry standards.

1. Material Selection The first step is the careful selection of materials. High-quality steel is chosen for reinforcement due to its tensile strength and durability. This steel reinforcement is combined with high-grade concrete that possesses excellent compressive strength.

2. Design and Engineering Engineers design the bottom ring to meet specific project requirements. This includes calculating load-bearing capacities and ensuring that the dimensions align with the overall mould specifications. Advanced CAD software is often utilized to create detailed designs that can be modified easily.

3. Fabrication of Steel Reinforcements Once the design is complete, the steel reinforcements are fabricated. This may involve cutting, bending, and welding steel bars to create the necessary shapes that will be incorporated into the concrete.

steel reinforced concrete pipe mould bottom ring manufacturer

4. Mould Construction The next step is constructing the mould itself. The bottom ring is typically formed from a strong, durable material that can withstand the hydraulic pressure of the concrete pouring process. Steel moulds are commonly used due to their longevity and ability to produce smooth finishes.

5. Integration of Reinforcement The steel reinforcement is then positioned within the mould. Precise placement is crucial, as it ensures that the steel is effectively embedded in the concrete once it is poured.

6. Concrete Pouring With the reinforcement in place, the next step is pouring the concrete into the mould. This process must be conducted meticulously to avoid air pockets and ensure an even distribution of the material.

7. Curing After pouring, the concrete must be cured adequately to achieve the desired strength. This may involve maintaining specific temperature and humidity levels over a set period.

8. Quality Control The final product undergoes rigorous quality control testing, including dimensional checks and strength assessments, to ensure it meets the specified standards.

Advantages of Steel Reinforced Concrete Pipe Mould Bottom Rings

The use of steel reinforced concrete pipe mould bottom rings offers several advantages

- Increased strength The combination of steel and concrete provides unmatched durability and resistance to external stressors. - Enhanced longevity SRCPs are designed to last longer than traditional materials, reducing the frequency of replacements and repairs. - Cost-effectiveness Although the initial investment may be higher, the long-term savings due to reduced maintenance and longer service life make SRCPs a cost-effective solution. - Sustainability The use of recycled materials in the manufacturing process can further enhance the sustainability of SRCPs, making them an environmentally friendly choice.

In conclusion, the manufacturing of steel reinforced concrete pipe mould bottom rings is a sophisticated process that ensures the production of high-quality, durable concrete pipes. By understanding the significance and advantages of this component, stakeholders in the construction and infrastructure sectors can make informed decisions that enhance their projects’ overall performance and sustainability.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025