ديسمبر . 03, 2024 16:48 Back to list

Manufacturers of Concrete Pipe Bottom Rings for FRC Applications and Solutions

The Importance of FRC Concrete Pipe Bottom Rings in Modern Infrastructure

In the ever-evolving landscape of construction and infrastructure development, the need for durable, reliable, and efficient materials is paramount. Among these materials, FRC (Fiber Reinforced Concrete) has emerged as a frontrunner in enhancing the structural integrity and longevity of various applications. One of the critical components in the implementation of FRC is the concrete pipe bottom ring, particularly in the context of manufacturers who specialize in delivering high-quality, sturdy solutions for infrastructure projects.

What is FRC Concrete?

Fiber Reinforced Concrete (FRC) is a composite material that combines conventional concrete with fibrous materials, such as steel fibers, polypropylene fibers, or glass fibers. This integration enhances the mechanical properties of concrete, making it more resilient to cracking, impact, and fatigue. FRC is particularly advantageous in civil engineering applications where high performance is required. It offers improved tensile strength and ductility, allowing structures to withstand harsher environmental conditions.

The Role of Concrete Pipe Bottom Rings

Concrete pipe bottom rings play a crucial role in the construction and maintenance of drainage systems, sewage systems, and various underground infrastructures. They are designed to provide a secure, stable base for concrete pipes, ensuring proper alignment and support. The bottom ring helps distribute the load evenly and reduces the risk of settlement or misalignment over time, which can lead to costly repairs and infrastructure failures.

When made from FRC, these bottom rings exhibit enhanced durability and performance characteristics. The incorporation of fibers into the concrete mix offers improved resistance to moisture and environmental degradation, making them an excellent choice for applications in wet or unpredictable conditions.

Advantages of Using FRC Concrete Pipe Bottom Rings

1. Enhanced Load-Bearing Capacity FRC bottom rings are known for their exceptional load-bearing characteristics due to the fibers that reinforce the concrete. This feature is particularly important in areas with high traffic or heavy equipment operations.

2. Crack Resistance The fibers within FRC reduce the likelihood of cracks forming under stress, which is a common issue in standard concrete. This resilience translates to longer lifespans for the components and reduced maintenance costs.

frc concrete pipe bottom ring manufacturers

3. Improved Flexibility Unlike traditional rigid concrete, FRC provides some degree of flexibility, allowing structures to adapt to slight ground movements without compromising their integrity.

4. Reduced Weight FRC can often be formulated to reduce the overall weight of the components while maintaining strength, leading to easier handling and installation.

5. Cost-Effectiveness Though the initial costs of FRC manufacturing may be higher, the long-term benefits of reduced maintenance, repairs, and replacement make it a cost-effective solution for municipalities and construction companies.

The Role of Manufacturers in FRC Pipe Bottom Ring Production

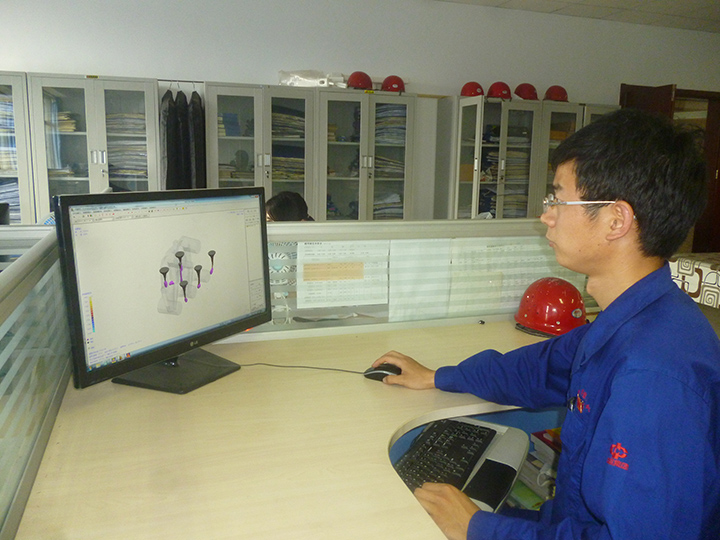

The importance of quality in the manufacturing process cannot be overstated. Manufacturers specializing in FRC concrete pipe bottom rings must adhere to stringent industry standards and utilize advanced technologies to ensure that their products meet the necessary specifications.

Key factors that reputable manufacturers focus on include

- Material Quality Sourcing high-quality raw materials to ensure the integrity of the FRC. - Innovative Production Techniques Utilizing state-of-the-art machinery and techniques to optimize the mixing and casting processes. - Quality Control Systems Implementing rigorous testing during and after production to guarantee the performance of the bottom rings under real-world conditions. - Customization Options Offering bespoke solutions tailored to meet specific project requirements, whether it be size, shape, or additional features.

Conclusion

FRC concrete pipe bottom rings represent a significant advancement in infrastructure materials, providing enhanced durability, flexibility, and efficiency. As cities and communities continue to grow, the demand for reliable foundations for their infrastructures increases. Partnering with manufacturers who are dedicated to quality and innovation in the production of FRC components is essential to meeting these challenges. By incorporating FRC concrete pipe bottom rings into construction strategies, engineers and developers can ensure the longevity and efficacy of their projects, paving the way for a more robust and sustainable infrastructure.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025