снеж . 29, 2024 12:06 Back to list

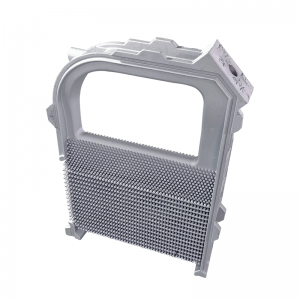

punching concrete pipe mold pallet

The Importance of Punching Concrete Pipe Mold Pallets in Construction

In the realm of construction and civil engineering, the utility of concrete pipe molds cannot be overstated. Among the various processes involved in concrete pipe production, the punching of concrete pipe mold pallets stands out as a pivotal method that enhances efficiency, strength, and overall quality of the pipes produced. Understanding the significance of this process and its implications for the construction industry can lead to better practices and improvements in production methodologies.

What are Concrete Pipe Mold Pallets?

Concrete pipe mold pallets are specialized tools used to shape and support concrete as it cures. These pallets play a crucial role during the manufacturing of concrete pipes which are essential components in drainage systems, sewage management, and municipal infrastructure. The molds need to be durable, precise, and capable of withstanding the substantial pressure that comes with pouring concrete.

The Punching Process

Punching refers to the method of applying force to create holes or indentations in the concrete mold pallets. This process can be performed using various techniques, including hydraulic punching as well as mechanical methods. The punched holes serve multiple purposes, such as facilitating air circulation, allowing for quicker curing, and improving the bonding of concrete materials used in the production of pipes.

One of the most significant advantages of punch holes in concrete pipe mold pallets is the enhanced curing process. Efficient air circulation helps reduce the risk of moisture entrapment, which can lead to defects in the finished pipe. Furthermore, the punched holes can contribute to better water drainage during the curing phase, ensuring that the concrete sets evenly and strengthens properly.

Benefits of Punching Concrete Pipe Mold Pallets

punching concrete pipe mold pallet

1. Improved Quality and Strength The punching process increases the overall structural integrity of the concrete pipes. By promoting better air circulation and water drainage, manufacturers can avoid common issues such as cracking and weakening, leading to more reliable and durable end products.

2. Increased Production Efficiency The quicker curing times obtained through punched molds allow manufacturers to produce pipes at a faster rate. This efficiency not only reduces production lead times but also lowers costs associated with labor and materials.

3. Enhanced Design Flexibility Punched molds can be tailored to accommodate custom designs and specifications based on the project requirements. Manufacturers can create intricate molds with specific hole patterns to achieve unique design elements for different types of concrete pipes.

4. Sustainability Utilizing punched mold pallets can also have positive implications for environmental sustainability. Faster curing processes can lead to shorter project timelines, which in turn can reduce resource consumption and waste. Additionally, the improved durability of the resultant pipes translates to a longer service life, minimizing the need for replacements and repairs.

Challenges and Considerations

Despite the numerous benefits, the punching process is not without its challenges. The precision in designing and creating punched molds is crucial; even minor errors can lead to significant defects in the pipes. Therefore, manufacturers must invest in advanced technology and skilled labor to ensure the molds are meticulously crafted. Furthermore, regular maintenance of mold pallets is essential to prolong their lifespan and ensure consistent quality.

Conclusion

In conclusion, the punching of concrete pipe mold pallets is a critical process in the manufacturing of concrete pipes, representing an intersection of innovation and practicality in construction. The advantages of improved strength, production efficiency, design flexibility, and sustainability contribute significantly to the overall quality and reliability of concrete pipes. As the construction industry continues to evolve with advancements in technology and sustainability, the importance of effective production techniques such as punching cannot be underestimated. Investing in these processes ultimately leads to better infrastructure, safer environments, and enhanced economic outcomes for communities worldwide.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025