снеж . 19, 2024 12:37 Back to list

Manufacturers of Pallets for Cement Pipe Molds and Stamps

The Role of Stamp Cement Pipe Mold Pallet Manufacturers in Construction

In the ever-evolving world of construction and infrastructure development, the demand for innovative and durable materials has never been higher. One essential component in this industry is the cement pipe, widely used for various applications, including drainage systems, sewage, and water supply. To meet the growing needs for these cement pipes, manufacturers specializing in stamp cement pipe molds, pallets, and related equipment have emerged as critical players in the manufacturing process.

Understanding the Manufacturing Process

The production of cement pipes begins with the creation of molds and pallets. Stamp cement pipe molds are specifically designed to shape and form the concrete during the curing process, allowing for efficient production while maintaining a high level of precision. These molds can vary in size and shape, depending on the specific requirements of the project. The use of advanced techniques and high-quality materials in mold production ensures that the final product meets industry standards for durability and performance.

Pallets also play a significant role in the manufacturing process. They are required for transporting and curing the molded pipes. A good pallet can enhance the efficiency of the production line, reducing the risk of damage during handling and storage. Manufacturers that specialize in producing cement pipe molds and pallets must pay close attention to the materials they use, as well as the design of the pallets, to ensure they can withstand the weight and stress of the concrete pipes during transportation.

Importance of Quality and Technology

The quality of both the mold and pallet significantly influences the final output. High-quality molds lead to precise and consistent pipe dimensions, which are essential for ensuring seamless installation and functionality. Manufacturers that invest in advanced technology, such as vibration and pressure systems, can produce molds that create high-density concrete, resulting in stronger and more durable pipes.

Furthermore, the adoption of sustainable practices in mold and pallet manufacturing is becoming increasingly essential. With growing concerns about environmental impact, manufacturers are now exploring eco-friendly materials and production methods. For example, using recycled materials in the production of molds and pallets can significantly reduce waste, contributing to a more sustainable construction industry.

The Market Demand

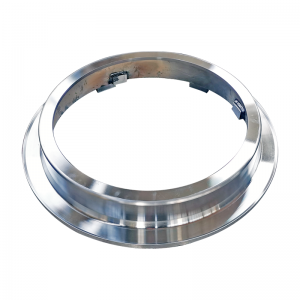

stamp cement pipe mold pallet manufacturers

The demand for cement pipes is steadily increasing due to urbanization and infrastructure expansion. Cities around the world require robust drainage systems and water supply lines, which in turn drives the need for efficient manufacturing processes for cement pipes. Stamp cement pipe mold pallet manufacturers are positioned to play a vital role in this growth, providing the necessary resources to meet the rising demand.

As the construction industry seeks more efficient and economical solutions, manufacturers that can offer innovative designs and technical support will likely thrive. Collaborations with construction companies can lead to tailored solutions that address specific project challenges, enhancing satisfaction and performance.

Challenges in the Industry

Despite the bright prospects, stamp cement pipe mold pallet manufacturers face challenges. The fluctuating prices of raw materials can impact production costs, forcing manufacturers to find ways to optimize their operations. Additionally, navigating regulatory requirements for construction materials adds another layer of complexity. Companies must remain agile and responsive to changing regulations to avoid disruptions.

Moreover, skilled labor shortages in manufacturing can pose a significant challenge. As technologies advance, the workforce must adapt and develop new skills to maintain quality standards and operational efficiency. Engaging in training programs and fostering a culture of continuous improvement within the workforce can help address these challenges.

Future Trends

Looking ahead, the industry is likely to see an increased focus on automation and digitalization. Incorporating cutting-edge technology into manufacturing processes can enhance precision, reduce labor costs, and improve production speeds. Manufacturers who embrace these changes not only improve their competitiveness but also contribute to the overall advancement of the construction industry.

In conclusion, stamp cement pipe mold pallet manufacturers play an essential role in the construction sector, producing the molds and pallets that are vital for efficient cement pipe production. As the demand for infrastructure continues to grow, these manufacturers must remain innovative and adaptive, ensuring they can meet the challenges and opportunities that lie ahead. By focusing on quality, sustainability, and technological advancements, they can help shape a better future for the construction industry.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025