снеж . 24, 2024 20:25 Back to list

steel reinforced concrete pipe mold bottom ring exporter

Exploring the Global Demand for Steel Reinforced Concrete Pipe Mold Bottom Rings

In the construction and infrastructure sector, the demand for durable, efficient, and cost-effective materials is paramount. One such material that has gained significant traction is the Steel Reinforced Concrete Pipe Mold Bottom Ring. As urbanization accelerates and the need for reliable drainage and sewage systems intensifies, the role of these specialized components becomes increasingly important. This article delves into the characteristics, manufacturing processes, export markets, and future prospects of Steel Reinforced Concrete Pipe Mold Bottom Rings.

Characteristics and Benefits

Steel Reinforced Concrete Pipe Mold Bottom Rings are essential components used to manufacture concrete pipes. They provide structural integrity, ensuring that the pipes can withstand the pressures of transportation, installation, and long-term use. The inclusion of steel reinforcement enhances the tensile strength of concrete, which is normally weak in tension. This combination results in pipes that are not only robust but also resistant to various environmental factors, including corrosion, moisture, and heavy loads.

One of the major advantages of these bottom rings is their versatility. They can be tailored to meet specific requirements based on the project's needs, whether it’s for stormwater drainage, sewage systems, or industrial applications. Their durability significantly reduces maintenance costs over time, making them a preferred choice for contractors and municipalities alike.

Manufacturing and Quality Control

The production of Steel Reinforced Concrete Pipe Mold Bottom Rings involves sophisticated processes that ensure high-quality outputs. The manufacturing process typically includes the following steps

1. Material Selection High-quality steel and concrete are selected based on the specifications required for the end product.

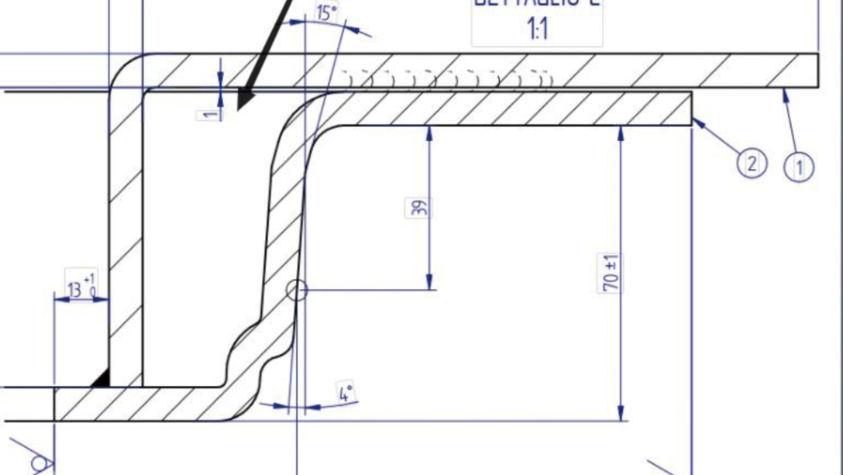

2. Molding Precision molds are used to shape the concrete into the desired form. These molds are designed to handle the rigors of the manufacturing process while ensuring consistency in each batch.

steel reinforced concrete pipe mold bottom ring exporter

4. Curing Once the concrete is poured, the curing process begins. Proper curing is critical to achieving the desired strength and durability of the concrete.

5. Quality Control Throughout the manufacturing process, rigorous quality control measures are employed. This includes testing the tensile strength, durability, and resistance to environmental factors of the finished product.

Export Markets and Opportunities

With the increasing global emphasis on infrastructure development, the market for Steel Reinforced Concrete Pipe Mold Bottom Rings is witnessing exponential growth. Countries in regions like North America, Europe, and Asia-Pacific are investing heavily in upgrading their infrastructure, thereby creating a robust demand for these products.

Exporters of Steel Reinforced Concrete Pipe Mold Bottom Rings have the opportunity to penetrate emerging markets where urban development is on the rise. In countries experiencing rapid economic growth, the need for reliable drainage and water management systems is critical. This presents a substantial opportunity for manufacturers and exporters who can provide high-quality products tailored to specific regional needs.

Challenges and Future Prospects

Despite the favorable market conditions, exporters face several challenges. Competition is fierce, with numerous players vying for market share. Additionally, tariffs and trade regulations can pose significant barriers to entry in certain markets. To succeed, exporters must focus on innovation, product differentiation, and establishing strategic partnerships with local firms.

The future of the Steel Reinforced Concrete Pipe Mold Bottom Ring market appears promising. As sustainability becomes a focal point in construction practices, the demand for durable and eco-friendly products will likely increase. By emphasizing environmentally responsible manufacturing processes and materials, exporters can align themselves with global trends and foster long-term growth.

Conclusion

Steel Reinforced Concrete Pipe Mold Bottom Rings play a crucial role in the construction and infrastructure landscape. As demand continues to grow globally, there are ample opportunities for exporters to thrive in this dynamic market. By focusing on quality, innovation, and sustainability, the future looks bright for this essential component of modern infrastructure.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025