дек. . 26, 2024 06:54 Back to list

Precision Casting Components Manufacturer for High-Quality Investment Casting Parts Production

The Importance of Investment Casting Parts Factory in Modern Manufacturing

Investment casting, also known as lost-wax casting, is a precision metal-forming process that has gained significant traction in various industries. Investment casting parts are widely used in aerospace, automotive, and medical applications due to their ability to produce complex geometries with high dimensional accuracy. Thus, the role of an investment casting parts factory is crucial in modern manufacturing, serving as a cornerstone for innovation and efficiency.

Understanding Investment Casting

Investment casting involves the creation of a wax pattern, which is covered in a ceramic shell. Once the ceramic hardens, the wax is melted away, creating a cavity that mimics the exact shape of the desired metal component. Molten metal is then poured into this cavity, resulting in a highly detailed and smooth-surfaced part. This method offers several advantages over traditional casting techniques, including the ability to produce intricate designs, reduce machining time, and minimize waste.

Quality and Precision

One of the standout features of investment casting is its exceptional quality and precision. Parts produced in investment casting can achieve tolerances as tight as +/- 0.005 inches, making it ideal for applications where dimensional accuracy is critical. This high level of precision significantly reduces the need for post-casting machining processes, which not only saves time but also lowers production costs.

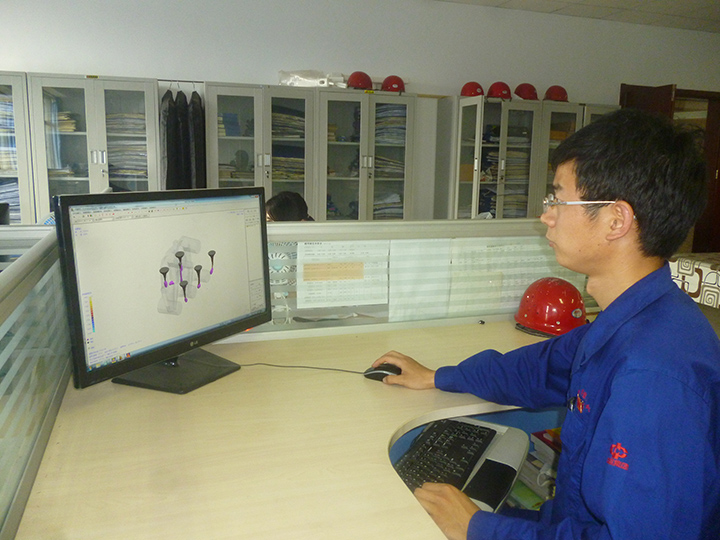

Investment casting parts factories invest heavily in quality control measures. They employ advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining to ensure that every part meets stringent industry standards. Regular inspections and testing, including metallurgical analysis and non-destructive testing, further guarantee the reliability and durability of the products.

Material Versatility

investment casting parts factory

Another key advantage of investment casting is the wide range of materials that can be used. From stainless steel and carbon steel to exotic alloys like Inconel and titanium, the versatility of materials available allows factories to cater to various sectors. This capability is particularly important in industries like aerospace, where the use of lightweight yet strong materials can lead to improved fuel efficiency and performance.

Sustainability and Efficiency

In recent years, sustainability has become a focal point in manufacturing. Investment casting processes are inherently more efficient than traditional methods, as they produce less scrap material and use energy more effectively. Additionally, many investment casting parts factories are adopting practices that minimize their environmental footprint. This includes recycling scrap metal and utilizing energy-efficient technologies, thereby contributing to a more sustainable manufacturing environment.

Challenges and Innovations

Despite its many benefits, the investment casting industry faces challenges, such as the initial costs associated with mold creation and the need for specialized skills in handling the intricate processes. However, ongoing innovations, including advancements in 3D printing and smart manufacturing, are changing the landscape. These technologies enable faster prototype development and more flexible production lines, making investment casting even more accessible to manufacturers.

Conclusion

An investment casting parts factory plays a pivotal role in the manufacturing ecosystem. By enabling the production of high-precision components from a variety of materials, these factories not only meet the demands of modern industries but also contribute to a more sustainable future. As technology continues to evolve, the investment casting process is likely to become even more refined, solidifying its importance in the world of manufacturing and engineering. The combination of quality, versatility, and innovation ensures that investment casting remains a vital manufacturing process for years to come.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025