дек. . 29, 2024 15:11 Back to list

steel casting exporters

The Global Landscape of Steel Casting Exporters

Steel casting is a vital component of numerous industries, ranging from automotive and aerospace to construction and machinery. As globalization continues to reshape trade dynamics, the role of steel casting exporters has become increasingly significant in meeting the growing demand for high-quality components. This article explores the current landscape of steel casting exporters, examining their key markets, challenges, and more.

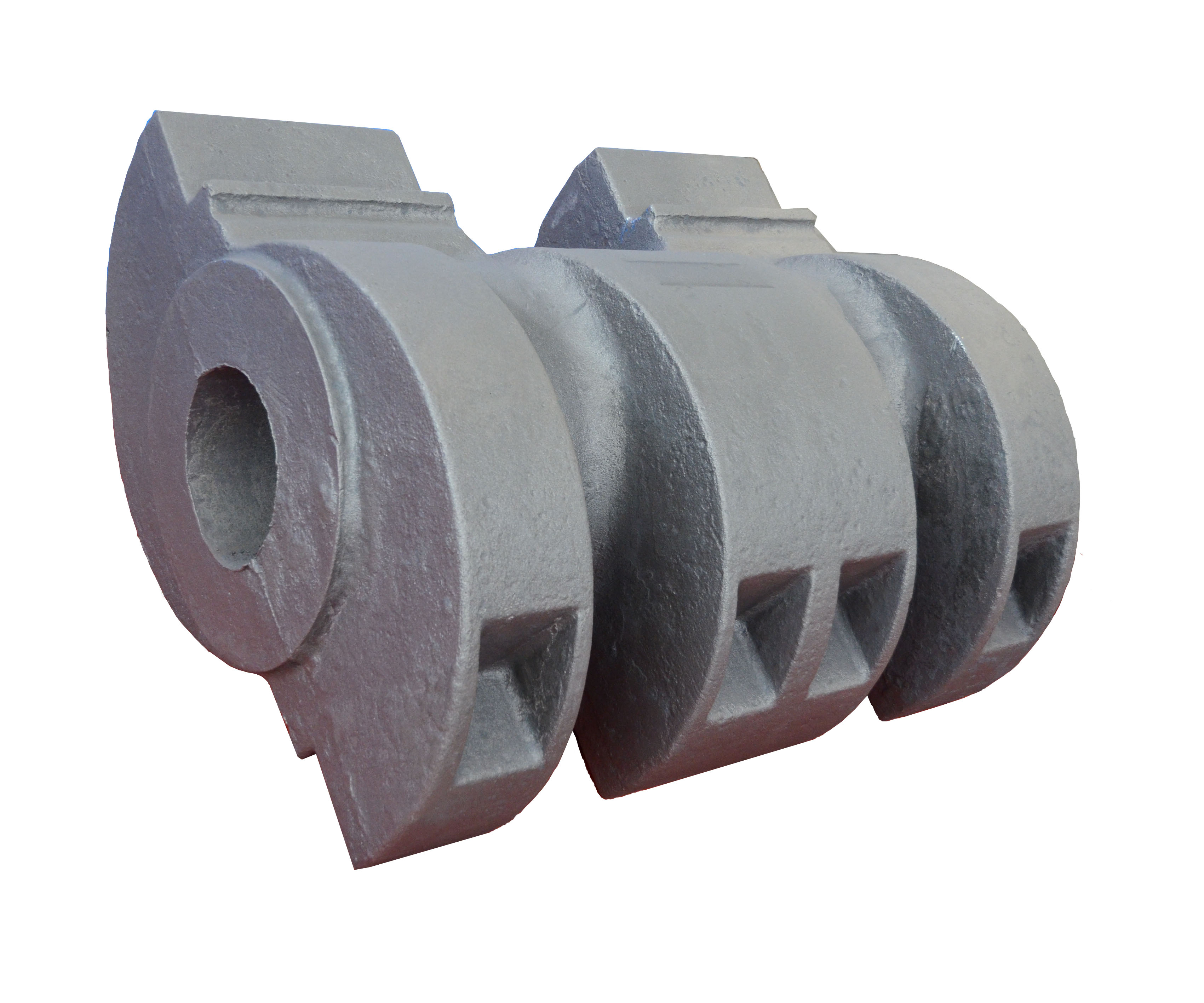

Understanding Steel Casting

Steel casting is a process in which molten steel is poured into molds to create complex shapes and components. This versatile manufacturing method is favored for its ability to produce durable, precise, and intricately designed parts. Steel castings can withstand immense pressures and are often used in critical applications where reliability is paramount. The process typically involves various types of steel, including carbon, alloy, and stainless steel, each offering unique properties suitable for specific applications.

Global Demand for Steel Castings

The demand for steel castings has been steadily increasing, particularly in emerging markets. Countries like China and India have witnessed explosive industrial growth, propelling the need for heavy machinery, automotive parts, and infrastructure components. As industries expand, so does the requirement for high-quality steel castings that can meet rigorous performance standards.

In addition to Asia, markets in North America and Europe continue to be significant consumers of steel castings, driven by the automotive sector and energy industries that require durable parts for engines, turbines, and other critical machinery. According to industry reports, the global market for steel castings is expected to grow at a compound annual growth rate (CAGR) of around 4-5% over the next few years.

Key Players in the Steel Casting Export Market

steel casting exporters

Several countries have established themselves as leading exporters of steel castings. Among them, China stands out as one of the largest producers, benefiting from its extensive manufacturing infrastructure and cost-effective production processes. Chinese steel casting exporters supply a vast array of industries and have managed to capture a substantial share of the global market.

The United States and Germany are also prominent players in the steel casting export arena. These countries are known for their stringent quality standards and advanced engineering capabilities, particularly in producing specialized or high-value components. Their focus on innovation and technology enables them to cater to niche markets that demand high-performance steel castings.

Another notable player is India, which has emerged as a competitive exporter due to its lower labor costs and increasing investment in modern manufacturing techniques. Indian steel casting exporters are progressively improving their quality standards and are actively expanding their reach in international markets.

Challenges Faced by Steel Casting Exporters

Despite the promising landscape, steel casting exporters face several challenges. One of the primary hurdles is the fluctuation in raw material prices. The cost of steel and other alloys can vary significantly, affecting profit margins for exporters. Additionally, geopolitical tensions and trade restrictions can pose risks to international trade, making it essential for exporters to navigate complex regulations and tariffs.

Another challenge is the emphasis on sustainability and environmental protection. As industries shift towards greener practices, steel casting exporters must adopt more sustainable production methods, including reducing waste and emissions. This transition often requires substantial investments in technology and processes, which can be a barrier for smaller exporters.

Conclusion

The steel casting export market is poised for growth, fueled by increasing industrial demand and advancements in manufacturing technology. As global trade continues to evolve, the importance of steel casting exporters cannot be overstated. They not only play a crucial role in supplying high-quality components but also contribute to the overall health of the industries they serve. By addressing the challenges they face and embracing innovation, steel casting exporters can navigate an increasingly competitive landscape and continue to thrive in the global market. In conclusion, the future of steel casting exports looks promising, with opportunities abound for those willing to adapt and innovate within this essential sector.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025