ডিসে. . 23, 2024 21:15 Back to list

Casting Parts Supplier for Quality Export Solutions and Manufacturing Services

The Role of Casting Parts Exporters in the Global Market

In today's interconnected world, the export of casting parts plays a critical role in various industries, including automotive, aerospace, machinery, and many others. Casting, a manufacturing process in which liquid material is poured into a mold and allowed to harden, allows for the creation of complex shapes and geometries that are often difficult or costly to achieve through other methods. As economies grow and industries expand, the demand for high-quality casting parts increases, and exporters are becoming essential players in fulfilling this need.

Understanding Casting Parts

Casting parts can be made from various materials, including metals, plastics, and ceramics, with metal casting being the most prevalent. This process can produce everything from engine blocks to intricate machinery components, highlighting its versatility. The primary methods of casting include sand casting, die casting, investment casting, and centrifugal casting, each serving different applications and industries.

The Importance of Casting Parts Exporters

Casting parts exporters act as intermediaries between manufacturers and global markets. They facilitate the movement of goods across borders, ensuring that high-quality parts reach consumers and industries that require them. The exporters are critical for several reasons

1. Market Access Exporters help local manufacturers access international markets, expanding their customer base and increasing revenue opportunities. By navigating regulatory hurdles and understanding market demands, exporters can bridge the gap between producers and customers.

2. Quality Assurance Reputable exporters focus on quality control, ensuring that the casting parts meet international standards and customer specifications. This focus on quality builds trust with clients and can result in ongoing business relationships, essential for sustainable growth.

3. Economic Impact The casting parts industry is a significant contributor to the economy. Exporters not only create jobs domestically but also stimulate growth in the manufacturing sector. By exporting casting parts, companies contribute to higher GDP and increased trade balances for their respective countries.

4. Innovative Solutions Exporters often stay at the forefront of technological advancements in casting processes and materials. By collaborating with manufacturers, they can offer innovative solutions to meet specific client needs, whether through the use of new materials, improved casting techniques, or advanced designing software.

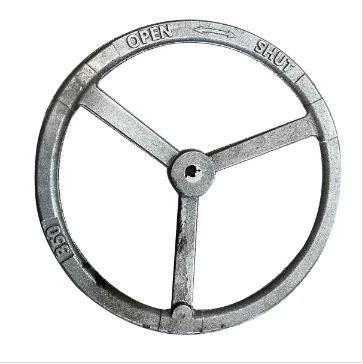

casting parts exporter

Challenges Faced by Exporters

While the opportunities for casting parts exporters are abundant, they also face several challenges.

- Regulatory Compliance Different countries have varying standards and regulations for importing casting parts

. Staying informed and compliant with these regulations is essential for successful exports.- Market Fluctuations Global market conditions can be unpredictable. Changes in demand due to economic shifts, trade policies, or even pandemics can significantly impact the export of casting parts.

- Supply Chain Issues Global supply chains are often complex and can be disrupted by various factors, such as geopolitical tensions, natural disasters, or transport bottlenecks. Effective management of logistics and supply chains is crucial for exporters to ensure timely delivery of parts.

The Future of Casting Parts Exporters

The future looks promising for casting parts exporters. As industries evolve and the demand for customized and high-quality components increases, the role of these exporters will only grow in significance. With advancements in automation, artificial intelligence, and additive manufacturing, the landscape of casting is changing. Exporters that adapt to these technological changes will likely thrive.

Furthermore, as sustainability becomes a central focus for manufacturing industries, casting parts exporters will need to embrace eco-friendly practices. This includes sourcing materials responsibly and implementing energy-efficient production methods to meet the growing consumer demand for sustainable products.

Conclusion

In conclusion, casting parts exporters are vital to the global supply chain, connecting manufacturers with international markets and enabling industries to flourish. While they face numerous challenges, their ability to innovate, comply with regulations, and adapt to market changes positions them as crucial players in the ever-evolving landscape of manufacturing. As the global economy continues to integrate, the importance of casting parts exporters will only increase, making them a key component of the manufacturing sector's future.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025