নভে. . 21, 2024 15:40 Back to list

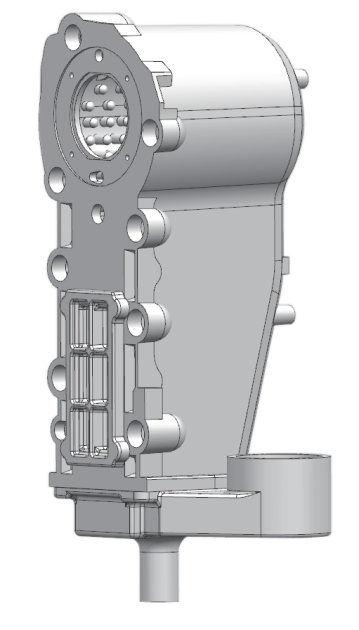

punch cement pipe mold pallet

Understanding the Role of Punch Molds in Cement Pipe Production

Cement pipes play a vital role in various infrastructure projects, such as drainage systems, sewage management, and water supply networks. The manufacturing process for these pipes involves the use of specialized molds, particularly punch molds. This article delves into the significance of punch molds in cement pipe production, their design features, manufacturing techniques, and overall impact on the industry.

The Importance of Cement Pipe Molds

In the production of cement pipes, molds are essential for shaping the concrete to achieve the desired dimensions and quality. Punch molds are specifically designed to create the inner holes of the pipes, ensuring they meet specific requirements for fluid flow and structural integrity. The precision of these molds is crucial, as any inaccuracies can lead to significant issues in the final product, including leaks and structural weaknesses.

Design Features of Punch Molds

Punch molds are characterized by their robust construction and intricate design features. Typically made from high-strength materials, they are engineered to withstand the high compressive forces generated during the cement casting process. Key design elements include

1. Shape and Size The mold must be tailored to accommodate various pipe diameters and lengths, as well as specific application needs, such as residential versus industrial usage.

2. Release Mechanism An effective mold includes a reliable release mechanism to facilitate the easy removal of the finished product without damaging its surface.

3. Ventilation Molds need to incorporate ventilated designs to allow trapped air to escape during the pouring of cement, ensuring uniform density and preventing bubble formation.

4. Surface Finish The interior surface of the mold should possess a finish that minimizes friction during the release of the pipe, ensuring a smooth, high-quality final appearance.

punch cement pipe mold pallet

Manufacturing Techniques for Punch Molds

The production of punch molds involves several advanced manufacturing techniques. Below are some of the prominent methods used

1. Machining Precision machining is employed to create intricate mold components, ensuring tight tolerances necessary for high-quality cement pipes. CNC (Computer Numerical Control) machining is a common method that enhances accuracy.

2. Casting Some molds are produced through casting methods, where molten metal or other materials are poured into a mold and allowed to solidify, providing durability and structural strength.

3. 3D Printing An emerging technique in mold production is 3D printing technology. This method allows for rapid prototyping and adjustments, enabling manufacturers to create custom molds more efficiently.

4. Heat Treatment To improve the wear resistance of punch molds, heat treatment processes are often applied in the final stages of production, extending the mold's lifespan.

Impact on the Cement Pipe Industry

The use of punch molds in the cement pipe manufacturing industry directly impacts the quality and performance of the pipes produced. High-quality molds contribute to

- Reduced Production Errors Precise molds lead to fewer defects in the pipes, minimizing wastage and production costs. - Enhanced Durability Well-designed molds produce pipes that are not only structurally sound but also resistant to wear and corrosion, thus increasing their service life. - Improved Efficiency Efficient mold designs speed up the production process, allowing manufacturers to meet increasing market demands while maintaining high standards of quality.

In conclusion, punch molds are integral to the cement pipe manufacturing process. Their design and manufacturing techniques significantly affect the quality and efficiency of production. As the construction and infrastructure industries continue to grow, advancements in mold technology will play a crucial role in meeting the challenges of producing reliable and durable cement pipes. Manufacturers that invest in high-quality punch molds will likely enhance their competitive edge in an ever-evolving market.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025