সেপ্টে. . 14, 2024 18:20 Back to list

temperature to melt aluminum

Understanding the Temperature Required to Melt Aluminum

Aluminum is one of the most versatile and widely used metals in various industries, ranging from aerospace and automotive to packaging and construction. One of the fundamental aspects of working with aluminum is understanding its melting point, which is crucial for processes like casting, welding, and recycling. This article delves into the temperature required to melt aluminum and discusses its implications in practical applications.

Understanding the Temperature Required to Melt Aluminum

The melting temperature of aluminum can be influenced by its purity and alloying elements. Pure aluminum has a melting point of around 660.3 degrees Celsius, but when alloyed with other metals, this temperature can vary. For instance, common aluminum alloys—such as those made with copper, magnesium, silicon, and zinc—have altered melting points due to the changes in their chemical composition. These alloys often exhibit improved strength, corrosion resistance, and other desirable properties, but their melting points can range from about 500 to 660 degrees Celsius, depending on the specific alloy.

temperature to melt aluminum

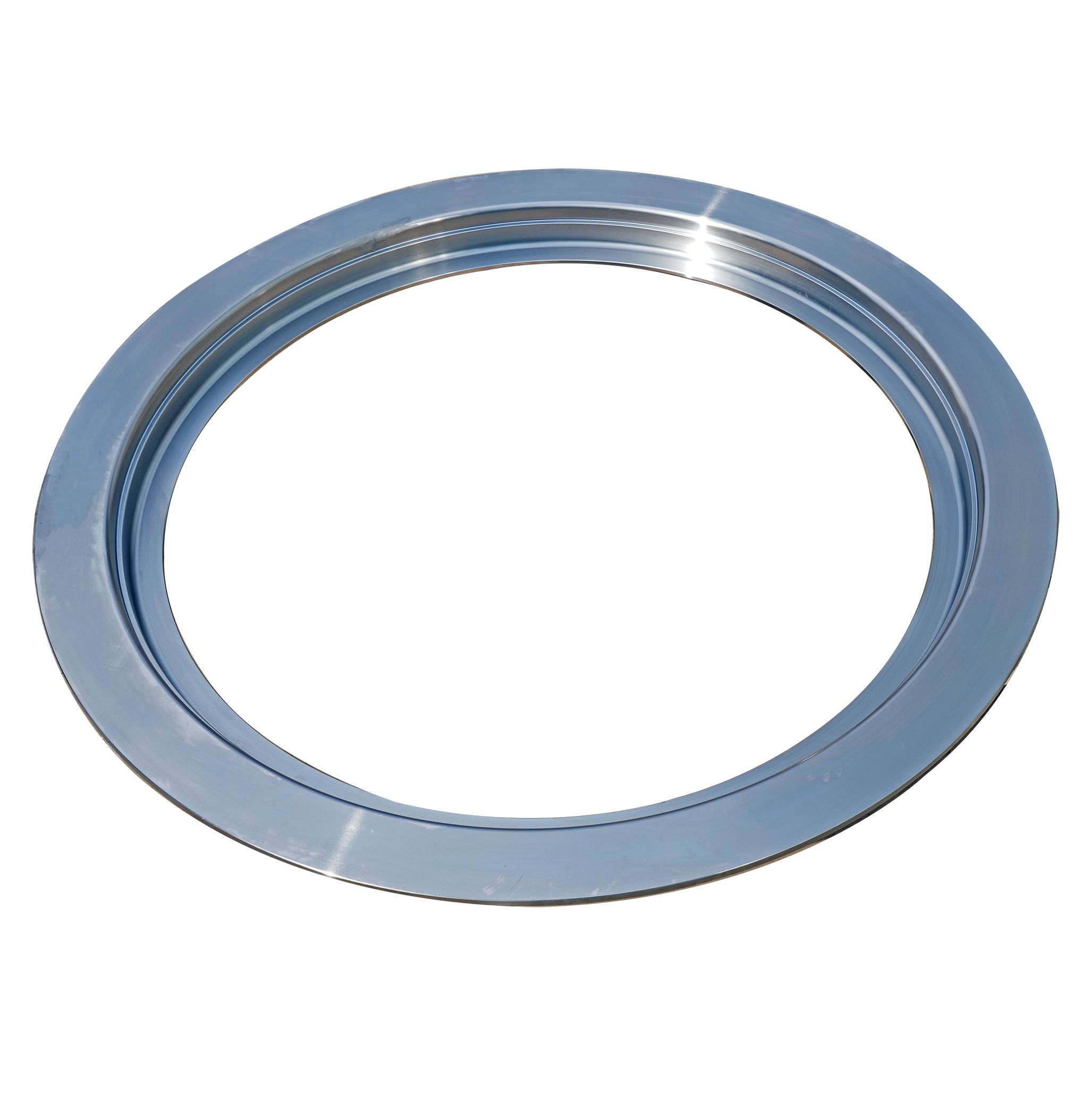

Understanding the temperature required to melt aluminum is essential for industries that rely on aluminum casting. In casting processes, manufacturers heat aluminum until it reaches a molten state and then pour it into molds to create desired shapes and components. If the temperatures are controlled improperly, it can lead to incomplete melting or oxidation of the aluminum, adversely affecting the quality of the final product.

In addition to casting, the melting temperature of aluminum plays a crucial role in welding. Different welding techniques, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), are employed to join aluminum components. It is vital for welders to maintain the temperature within a specific range to achieve a strong and durable weld. Overheating can cause the weld to become weak and brittle, while insufficient heat can lead to poor fusion between the aluminum pieces.

Recycling is another significant aspect of aluminum production. The recycling process involves melting down used aluminum products to create new materials. With the melting point remaining constant at around 660.3 degrees Celsius, recycled aluminum requires less energy to melt compared to primary aluminum extraction, which involves mining and refining bauxite ore. This energy efficiency highlights the environmental benefits of recycling aluminum, making it a sustainable choice in manufacturing.

In conclusion, the temperature required to melt aluminum is around 660.3 degrees Celsius, subject to variation depending on alloying elements. This property is critical in various applications, including casting, welding, and recycling, shaping the way aluminum is utilized across different industries. Understanding these temperature dynamics not only aids in improving manufacturing processes but also promotes sustainability through efficient recycling practices. With aluminum's ongoing importance in modern technology and engineering, mastering its melting characteristics remains an essential focus for professionals in the field.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025