nov. . 19, 2024 11:45 Back to list

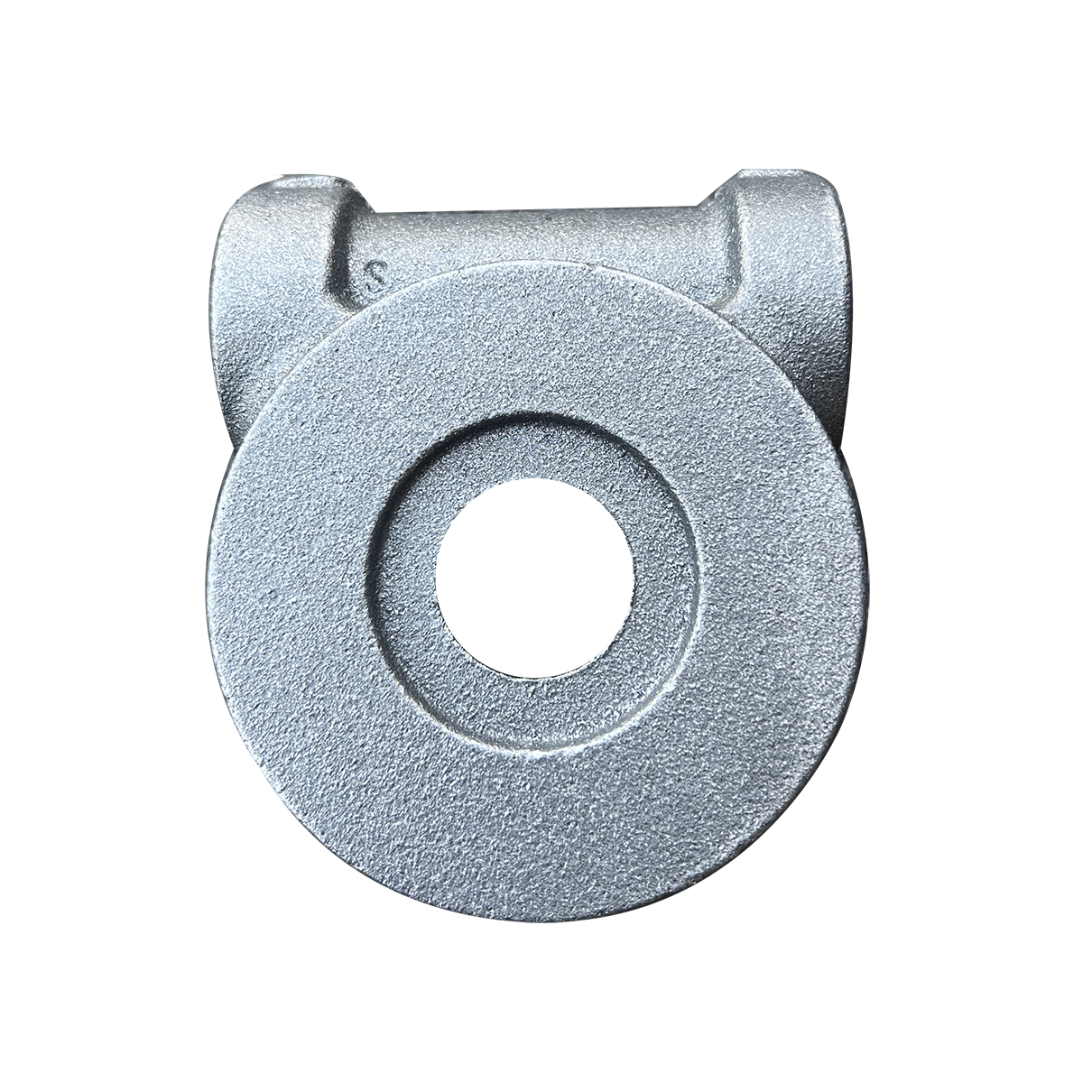

carbon steel lost wax casting factory

The Importance of Carbon Steel Lost Wax Casting in Modern Industry

Lost wax casting, also known as investment casting, is a highly versatile and intricate manufacturing process used for producing metal parts with complex geometries and high precision. Particularly, carbon steel lost wax casting has gained prominence in various industries due to its unique properties, making it an essential method in metal fabrication. This article explores the significance of carbon steel lost wax casting, its advantages, applications, and why finding a reliable factory for this process is crucial.

What is Carbon Steel Lost Wax Casting?

Carbon steel lost wax casting involves creating a wax model of the desired component, which is then encased in a liquid ceramic material to form a mold. Once the mold is set, the wax is melted and drained away, leaving a cavity in the shape of the original model. Molten carbon steel is then poured into this cavity to create a precise final product. The process allows for the production of intricate designs and fine details that are often challenging to achieve with traditional manufacturing methods.

Advantages of Carbon Steel Lost Wax Casting

1. Precision and Accuracy Lost wax casting offers exceptional dimensional accuracy, often achieving tolerances as tight as ±0.5 mm. This precision is crucial in industries where exact specifications are mandatory.

2. Complex Geometries The process allows for the creation of components with complex shapes and thin walls, making it suitable for various applications in aerospace, automotive, and medical industries, where intricate designs are often demanded.

3. Material Versatility Carbon steel, with its combination of strength, ductility, and resistance to wear and tear, is an ideal material for lost wax casting. It can be alloyed with other elements to enhance specific properties, making it adaptable for diverse applications.

4. Reduced Waste The lost wax process minimizes material waste compared to other metalworking techniques, as it utilizes a mold that can be reused multiple times, resulting in a more sustainable manufacturing process.

5. High-Quality Surface Finish Parts produced through lost wax casting typically exhibit a superior surface finish, reducing or eliminating the need for further machining, which can save time and costs.

Applications of Carbon Steel Lost Wax Casting

Carbon steel lost wax casting has a broad range of applications, reflecting its versatility and excellence in manufacturing. Some key sectors include

- Aerospace Components such as turbine blades, housings, and critical structural parts benefit from the precision and strength offered by carbon steel.

carbon steel lost wax casting factory

- Automotive High-stress components such as engine brackets, pump housings, and transmission parts are commonly produced using this technique, ensuring durability and performance

.- Medical Devices Instruments and implants often require precise geometries and high standards, making lost wax casting an excellent choice for producing reliable medical components.

- Industrial Equipment Various tools and machinery components are cast in carbon steel due to its wear-resistant properties, ensuring longevity and reliability in industrial applications.

Choosing a Reliable Carbon Steel Lost Wax Casting Factory

Finding a reputable factory specializing in carbon steel lost wax casting is crucial for ensuring quality, precision, and efficiency. When selecting a manufacturer, consider the following factors

1. Experience and Expertise A factory with a proven track record in lost wax casting can better handle complex designs and provide valuable insights during the design process.

2. Technology and Equipment Advanced casting technologies and well-maintained equipment are essential for achieving high-quality results.

3. Quality Control Look for factories that implement strict quality control measures, ensuring that all products meet the required standards and specifications.

4. Customer Support A manufacturer that offers robust customer support can assist you in navigating the complexities of the casting process and provide timely updates on production status.

5. Certifications Industry certifications can be indicative of a factory’s commitment to quality and adherence to international standards.

Conclusion

Carbon steel lost wax casting is a sophisticated manufacturing process that plays a vital role in producing high-quality, precision-engineered components across various industries. Its advantages in terms of accuracy, complexity, and material efficiency make it an ideal choice for modern manufacturing challenges. By selecting a reliable factory for this process, businesses can ensure that they achieve the best possible results, driving innovation and success in their respective fields.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025