nov. . 21, 2024 05:59 Back to list

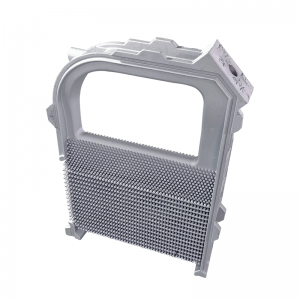

carbon steel lost wax casting manufacturer

The Advantages of Using Carbon Steel in Lost Wax Casting

Lost wax casting, also known as investment casting, is a precision manufacturing process widely used to produce complex metal parts. Among the various materials that can be utilized in this casting technique, carbon steel stands out for its unique combination of properties, making it an ideal choice for numerous applications. This article explores the benefits of carbon steel lost wax casting and highlights why it is favored by manufacturers around the world.

Understanding Lost Wax Casting

Lost wax casting is an ancient technique that involves creating a wax model of the desired part, which is then coated in a ceramic material to form a mold. Once the mold is complete, it is heated to eliminate the wax, leaving a hollow cavity that can be filled with molten metal. After the metal cools and solidifies, the mold is broken away to reveal the final product. This method allows for exceptional detail and intricate designs, making it suitable for industries such as aerospace, automotive, and medical equipment fabrication.

The Role of Carbon Steel

Carbon steel, an alloy made primarily of iron and carbon, possesses several advantageous characteristics that enhance its performance in lost wax casting. One of the most significant benefits is its strength and durability. Parts made from carbon steel exhibit high tensile strength, making them suitable for heavy-duty applications where resistance to wear and tear is crucial.

Moreover, carbon steel has excellent casting fluidity; it can easily fill complex molds, which is essential in lost wax casting. This property reduces the likelihood of defects such as voids and inclusions, ensuring that the final product meets stringent quality standards. Additionally, the ability to cast detailed designs enhances the versatility of carbon steel in various applications.

Cost-Effectiveness

Another compelling reason to choose carbon steel for lost wax casting is its cost-effectiveness. Compared to other materials like stainless steel or aluminum, carbon steel is generally more affordable, making it an attractive option for manufacturers looking to minimize production costs without compromising quality. This economic advantage allows businesses to remain competitive in an increasingly challenging market.

carbon steel lost wax casting manufacturer

Versatility

Carbon steel can be alloyed with various elements to enhance specific properties, such as corrosion resistance or hardness, thereby expanding its applicability. For instance, adding alloying elements like manganese or nickel can improve the material's toughness and resistance to impact. This flexibility allows manufacturers to tailor materials to suit particular requirements, making carbon steel a versatile choice for diverse industries.

Environmentally Friendly

In an era where sustainability is paramount, the use of carbon steel in lost wax casting presents an environmentally friendly option. The casting process generates minimal waste compared to other manufacturing methods, and the materials used can often be recycled. This aligns with global efforts to reduce industrial waste and promote sustainable practices.

Quality Assurance

When manufacturing carbon steel components through lost wax casting, quality assurance is critical. Reputable manufacturers implement rigorous quality control measures throughout the casting process to ensure that each part meets specified tolerances and standards. This includes thorough inspections and testing of material properties, which ultimately leads to greater reliability in the final products.

Conclusion

In conclusion, carbon steel lost wax casting offers a range of benefits that make it a popular choice among manufacturers across various industries. The strength, durability, cost-effectiveness, versatility, and environmental sustainability of carbon steel components position them as a superior option for meeting technical requirements and customer demands. As technology continues to evolve, the applications of carbon steel in lost wax casting are likely to expand, furthering its importance in modern manufacturing. By partnering with experienced lost wax casting manufacturers, businesses can harness the advantages of carbon steel to achieve high-quality results tailored to their specific needs.

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025