des. . 06, 2024 05:25 Back to list

Top Manufacturers of Bottom Rings for FRC Concrete Pipe Moulds and Accessories

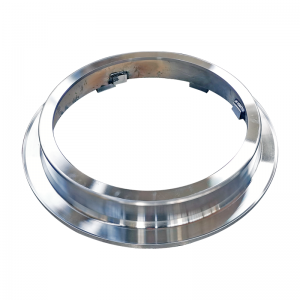

The Importance of FRC Concrete Pipe Mould Bottom Ring Manufacturers

In the construction and infrastructure industry, the efficiency and durability of materials are paramount. This necessity has led to the emergence of various manufacturing processes and materials that enhance the resilience of structures. Among these innovations, Fiber Reinforced Concrete (FRC) has gained significant attention, particularly in the production of concrete pipes. FRC concrete pipe mould bottom rings play a crucial role in the overall integrity and efficiency of these pipes, making the role of their manufacturers essential.

Understanding FRC Concrete Pipe Moulds

Fiber Reinforced Concrete is a composite material that includesFibers made from steel, glass, or synthetic materials. These fibers are added to concrete to enhance its physical properties, including tensile strength, ductility, and impact resistance. The use of FRC in the production of concrete pipes has revolutionized the construction of drainage systems, sewer lines, and other infrastructure components. The moulds used for casting these pipes, particularly the bottom rings, are critical in ensuring that the final product meets the required standards for durability and performance.

Manufacturers of FRC concrete pipe mould bottom rings need to understand several key factors to produce high-quality results. First and foremost, they must be proficient in the design and fabrication of moulds that can withstand the stresses involved in the curing and transportation of heavy concrete pipes. This requires a combination of engineering acumen, experience in materials science, and innovative production techniques.

Design Considerations for Moulds

The design of FRC concrete pipe moulds is a complex undertaking. Manufacturers must consider the weight, load-bearing capacity, and dimensional accuracy of the moulds to ensure that they can produce bottom rings that fit seamlessly into the overall pipe structure. Additionally, the moulds should allow for easy release of the cured concrete, minimizing any damage to the bottom rings and ensuring a smooth surface finish.

Another crucial aspect is the choice of raw materials used in the moulds themselves. High-quality steel or robust composite materials are often preferred to ensure longevity and reliability. The surface treatment of these moulds also plays a significant role; a non-stick coating can improve the efficiency of the production process and ensure that the concrete cures evenly.

frc concrete pipe mould bottom ring manufacturers

The Manufacturing Process

The process of manufacturing FRC concrete pipe mould bottom rings typically involves several stages. First, the design is created using advanced CAD software to ensure precision. Next, the chosen materials are cut and formed into the required shape. CNC (Computer Numerical Control) machines are often used to achieve high levels of accuracy and efficiency in this stage.

Following the preparation of the moulds, manufacturers must carry out quality control checks to ensure that every mould meets industry standards. This includes examining the dimensional accuracy, surface finish, and structural integrity of the moulds.

The Role of Technology

Advancements in technology continue to improve the efficiency and quality of FRC concrete pipe mould production. The integration of automation and robotics in the manufacturing process allows for greater consistency and speed. Moreover, manufacturers can utilize simulation software to predict the behavior of concrete in the moulds, enabling them to optimize designs before production.

Conclusion

The role of FRC concrete pipe mould bottom ring manufacturers is increasingly vital in today’s construction industry. As infrastructure projects grow in complexity and demand for high-performance materials becomes more pronounced, these manufacturers must adapt and innovate continuously. By focusing on quality, precision, and the use of advanced technologies, they can ensure that the concrete pipes produced are durable and reliable, contributing positively to the longevity and safety of infrastructure systems worldwide. As the demand for robust engineering solutions continues to rise, the expertise of FRC concrete pipe mould manufacturers will play an indispensable role in shaping the future of construction.

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025