Cast Steel Rubber Ring Joint Reinforced Concrete Pipe Mold Pallet, Bottom Ring, Base Ring

Product Description

The bottom ring/bottom tray/bottom pallet is a key part during reinforced concrete/cement pipe production. It is used for supporting/lifting the reinforcement cage, the pipe mold, and all the concretes during producing a pipe, after finishing the production of a pipe, the bottom pallets/bottom ring/bottom tray will still support the reinforced concrete/cement pipe till the pipe is completely cured, and then the pallets/ring/tray will be reused in another next circulation.

The bottom ring/pallets/tray can be made of cast steel, ductile iron, or punched/stressed/stamped.

Our company is very skilled and experienced in manufacturing the concrete pipe mold pallets/bottom rings/bottom trays. We have manufactured more than 7000pcs of bottom pallets covering the size range from 300mm to 2100mm for our overseas customers.

The pallets are obligate parts while producing a reinforced concrete/cement drainage pipe, it is placed at the bottom and inside a pipe mold for supporting the outside pipe mold and the reinforcement cage. It must be strong enough so that it can support tons of materials on it, so we produced it with special cast steel, it has the characteristic of higher strength, wear-resisting, no deformation, and long life.

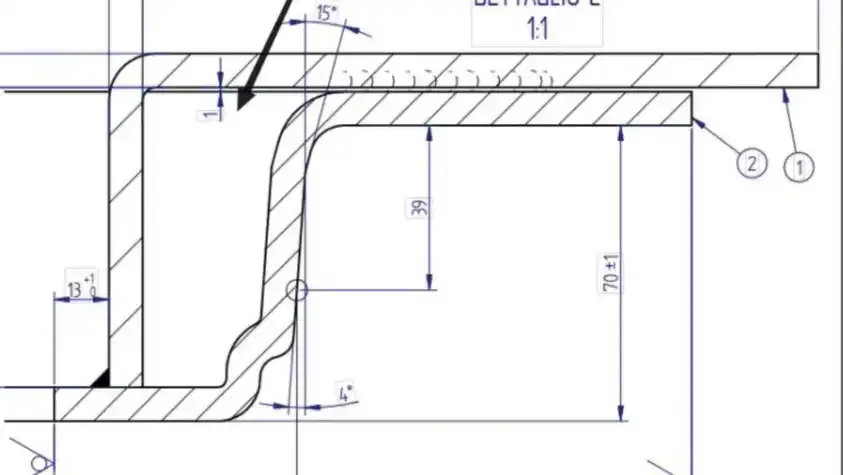

Product main technique data

|

Material: |

Special cast steel |

Cement pipe joint type: |

Rubber ring joint |

|

Dimension tolerance: |

+-0.5mm |

Pallets size range: |

300mm to 2100mm |

|

Working surface roughness: |

≦Ra3.2 |

Production technology: |

Casting,annealing, welding, machining |

|

Product unit weight: |

18kgs to 600kgs |

Product attribution: |

Customized products according to customer’s drawings |

The main production technology process

Drawings→ opening mold→ molding→ casting→ annealing→ rough machining→ welding→ finish machining→ packing

Packaging & Shipping

*Packaging: Steel pallet for bearing the weight of pallets + slushing oil for anti-rust + steel wire rope for securing the package + plastic film for dust protection

*To be shipped by 20’OT container

|

|

Payment & Delivery

* Payment Terms: 30% down payment by T/T, balance before shipment by T/T

* Delivery Terms: usually within 3 months to 7 months depending on order quantity

Application

| These pallets are used in the cement products industries, for producing reinforced concrete pipes. With the large quantity of pallets, your pipe-making machine can produce a pipe very soon, almost a pipe can be produced every 2-3 minutes. |  |

|

|

A picture of the rubber ring joint pipe produced with the pallets |