Pro . 30, 2024 00:11 Back to list

Durable Steel Pipe Molds for Efficient Casting and Pallet Solutions

Cast Steel Pipe Mold Pallets Enhancing Efficiency in Pipe Manufacturing

In the ever-evolving world of manufacturing, especially in the pipe industry, the significance of reliable and efficient tools cannot be overstated. One such tool that has gained prominence in recent years is the cast steel pipe mold pallet. This specialized equipment plays a critical role in the production of cast steel pipes, ensuring quality and efficiency while streamlining the manufacturing process.

Understanding Cast Steel Pipe Mold Pallets

Cast steel pipe mold pallets are robust platforms designed to support the molds used in the casting process. These pallets are typically fabricated from high-quality steel, offering strength and durability essential for handling the heavy and often intricate molds used in pipe production. The primary purpose of these pallets is to facilitate the pouring of molten steel into the molds, ensuring that the production process runs smoothly and efficiently.

One of the key features of cast steel pipe mold pallets is their ability to withstand extreme temperatures and resist deformation over time. In the pipe manufacturing process, molds are subjected to high thermal stress. Therefore, a pallet that can maintain its structural integrity while exposed to these conditions is vital for ensuring the quality of the final product.

Benefits of Using Cast Steel Pipe Mold Pallets

1. Enhanced Durability Cast steel's inherent strength makes these pallets highly durable, capable of withstanding the rigors of the manufacturing process. Unlike wooden or plastic alternatives, steel pallets do not warp or deteriorate, leading to a longer lifespan and reduced replacement costs.

2. Improved Efficiency The design of cast steel pipe mold pallets also enables quicker loading and unloading of molds. This efficiency in handling minimizes downtime during the production process, allowing manufacturers to increase their output and meet market demands promptly.

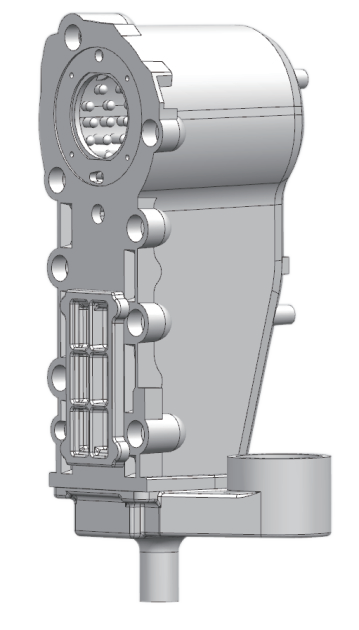

cast steel pipe mold pallet

3. Precision and Reliability Steel mold pallets provide a stable and level surface for molds, ensuring consistent and accurate casting. This precision translates to higher quality pipes with fewer defects, enhancing customer satisfaction and reducing waste.

4. Safety Features The stability and durability of cast steel pallets contribute to workplace safety. With their robust construction, they are less prone to tipping or breaking, thereby minimizing the risk of accidents on the production floor.

5. Cost-Effectiveness While the initial investment in cast steel mold pallets may be higher than alternatives, their long-term benefits significantly outweigh the costs. The durability, reduced maintenance, and increased output lead to greater overall savings for manufacturers.

Applications in Pipe Manufacturing

Cast steel pipe mold pallets are versatile and can be used in various pipe manufacturing processes, including drainage pipes, water supply pipes, and industrial piping systems. Their ability to support different mold designs makes them an essential component in creating pipes of various sizes and specifications.

In addition, as industries face increasing pressure to produce high-quality products while minimizing environmental impacts, the use of efficient molds and pallets can help streamline operations and reduce material waste.

Conclusion

As the demand for high-quality cast steel pipes continues to rise, manufacturers are constantly seeking ways to improve their production processes. The incorporation of cast steel pipe mold pallets into the manufacturing workflow represents a significant advancement in achieving efficiency, precision, and durability. By investing in these specialized tools, companies can enhance their operational capabilities, lower production costs, and meet the stringent demands of today’s market. As a result, cast steel pipe mold pallets are not just an accessory in the production process; they are a vital element in the evolution of modern pipe manufacturing.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025