Pro . 03, 2024 14:29 Back to list

china dry cast reinfored concrete pipe mold bottom ring

The Role of Dry Cast Reinforced Concrete Pipe Molds in Modern Construction

In the realm of modern construction and civil engineering, the demand for durable and reliable infrastructure is ever-increasing. One significant component contributing to this demand is the use of dry cast reinforced concrete pipe (RCP), which plays a crucial role in drainage systems, stormwater management, and various structural applications. Central to the production of these concrete pipes is the bottom ring mold, an essential tool that ensures precision, quality, and efficiency in the manufacturing process.

Understanding Dry Cast Reinforced Concrete Pipes

Dry cast reinforced concrete pipes are designed to withstand harsh conditions while providing optimal performance. Unlike traditional wet mix concrete, dry cast concrete contains less water, which allows for a more robust and denser final product. The absence of excessive moisture not only accelerates the curing process but also minimizes shrinkage, leading to improved structural integrity and longevity.

The reinforcement within these pipes often consists of steel bars or fibers, enhancing their resistance to tensile stresses and providing additional support against external loads. This makes dry cast reinforced concrete pipes suitable for a variety of applications, including sewage disposal, stormwater management, and even in the construction of highways and bridges.

The Importance of Molds in Pipe Production

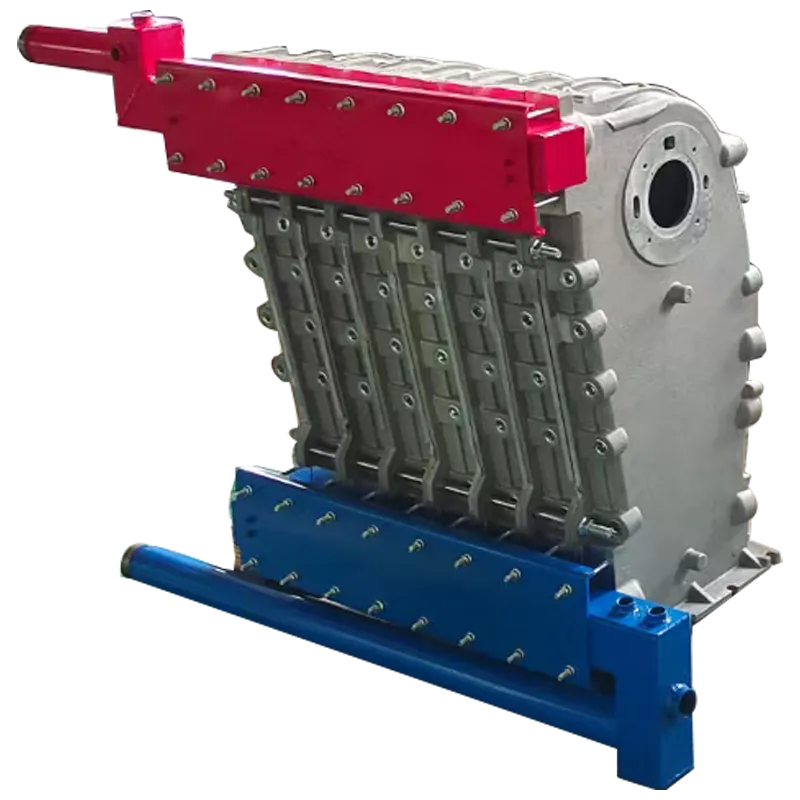

The manufacturing process of dry cast reinforced concrete pipes relies heavily on the use of molds. These molds come in various forms, and one of the most critical components is the bottom ring mold. This specific mold is responsible for shaping the base of the concrete pipe, ensuring that it meets the required specifications and standards.

The bottom ring mold is designed to facilitate the accurate placement of reinforcement materials while maintaining the correct dimensions of the pipe. Precision in the mold design is crucial, as any deviation can lead to structural failures or deficiencies in the pipe’s performance. Additionally, the use of high-quality materials in the mold construction contributes to the durability and lifespan of the molds themselves, reducing the need for frequent replacements.

china dry cast reinfored concrete pipe mold bottom ring

Innovations in Mold Technology

Recent advancements in mold technology have revolutionized the production of dry cast reinforced concrete pipes. Manufacturers are now investing in high-performance molds that combine efficiency with enhanced precision. These innovations include the use of advanced materials that resist wear and tear, as well as designs that simplify the demolding process.

Furthermore, the integration of automation and digital technologies allows for better control over the manufacturing process. Automated systems can streamline operations, reduce labor costs, and ensure consistency in product quality. The ability to track and monitor each stage of production also translates to improved efficiency and reduced production times.

Environmental Considerations

As the construction industry continues to pivot towards sustainability, the production of dry cast reinforced concrete pipes aligns with these environmental goals. The use of durable materials minimizes the frequency of replacements, resulting in fewer resources consumed over time. Additionally, advancements in the production process reduce waste and energy consumption, further contributing to a more sustainable approach to infrastructure development.

Conclusion

The importance of dry cast reinforced concrete pipes and their molds cannot be overstated in the modern construction industry. The bottom ring mold plays a pivotal role in shaping these essential components, ensuring their reliability and durability. As technology continues to evolve, the future of pipe production looks promising, with innovations that enhance quality, efficiency, and sustainability. With the ongoing focus on building resilient infrastructure, dry cast reinforced concrete pipes will undoubtedly remain a cornerstone in civil engineering projects around the world.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025