Říj . 18, 2024 13:47 Back to list

Comparison of Ductile Iron and Cast Iron Properties and Applications for Engineering Use

Ductile iron and cast iron are two widely utilized materials, particularly in the fields of engineering and manufacturing. Both types of iron have unique properties, applications, and advantages, making them suitable for various uses. Understanding their differences and similarities can help engineers and manufacturers choose the right material for their specific needs.

Ductile Iron An Overview

Ductile iron, also known as nodular cast iron or spheroidal graphite iron, is a type of cast iron that has undergone a process to improve its ductility. It is produced by adding small amounts of elements such as magnesium to molten iron, which alters the structure of the graphite present in the alloy. This results in spherical (nodular) graphite inclusions, as opposed to the flake-shaped graphite found in traditional cast iron. The spherical shape significantly enhances the mechanical properties of the iron.

One of the most notable characteristics of ductile iron is its remarkable strength and toughness. Compared to standard cast iron, ductile iron exhibits higher tensile strength and better elongation properties, making it suitable for applications that require durability and resistance to impact. Additionally, ductile iron has excellent fatigue resistance, which is crucial for components subjected to cyclic loads. Because of these properties, ductile iron is used in a variety of applications, including automotive components, heavy machinery parts, and pipe systems.

Cast Iron A Traditional Material

Cast iron is an alloy of iron that contains a higher carbon content, usually between 2% and 4%. This high carbon content, combined with silicon, gives cast iron its distinctive characteristics, such as excellent casting properties and wear resistance. The most common forms of cast iron include gray iron, white iron, and malleable iron. Gray cast iron, with its flake-like graphite structure, is the most widely used variety due to its good machinability and damping capacity.

While cast iron is known for its brittleness, it has excellent compressive strength and can withstand high temperatures. This makes it a suitable choice for applications like engine blocks, cookware, and heavy industrial machinery. However, the brittleness can be a disadvantage in situations where tensile strength and ductility are necessary. In such cases, ductile iron often proves to be the superior choice.

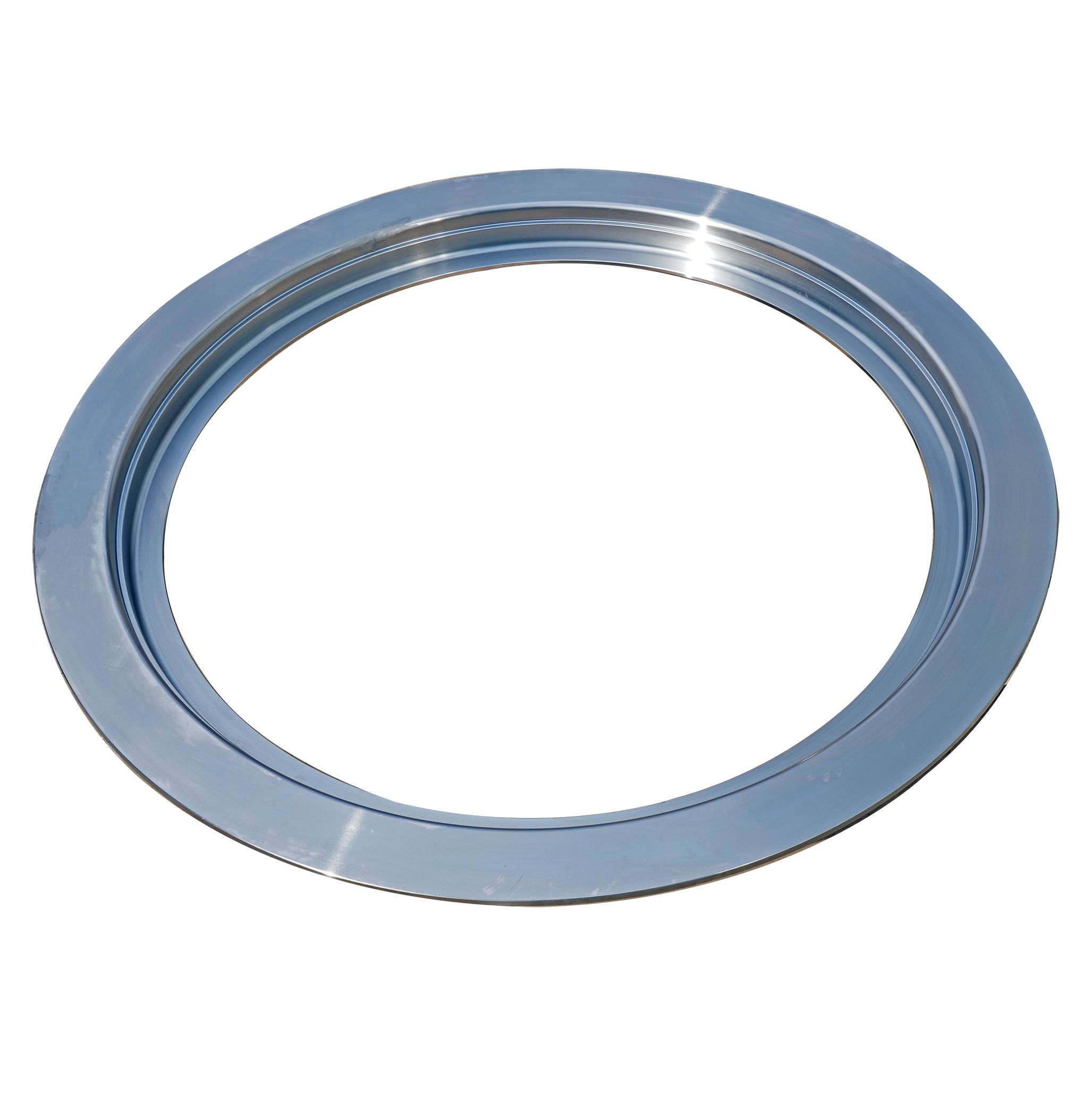

ductile iron and cast iron

Comparative Analysis of Ductile Iron and Cast Iron

When comparing ductile iron and cast iron, several key differences emerge. Ductile iron is significantly more ductile and has a higher tensile strength than cast iron. This makes ductile iron ideal for applications where flexibility, resilience, and impact resistance are required. In contrast, traditional cast iron excels in applications that demand excellent wear resistance and thermal conductivity but may fall short in terms of toughness.

Cost is another factor to consider. Ductile iron is generally more expensive to produce due to the additional materials and processing steps involved in its production. However, when long-term performance, durability, and reduced maintenance costs are considered, the investment in ductile iron may be justified.

Applications and Conclusion

Ductile iron is increasingly being used in various applications, including automotive parts like crankshafts, pipe fittings, and agricultural equipment, because of its superior mechanical properties. Cast iron remains popular for specific products such as engine blocks and cooking pots, where its unique characteristics are advantageous.

In conclusion, the choice between ductile iron and cast iron ultimately depends on the specific requirements of the application at hand. While ductile iron offers superior ductility and strength, cast iron provides excellent casting characteristics and thermal stability. For engineers and manufacturers, understanding the differences and applications of these two materials is crucial in making informed decisions that influence performance, cost, and longevity of the final product.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025