Úno . 11, 2025 10:50 Back to list

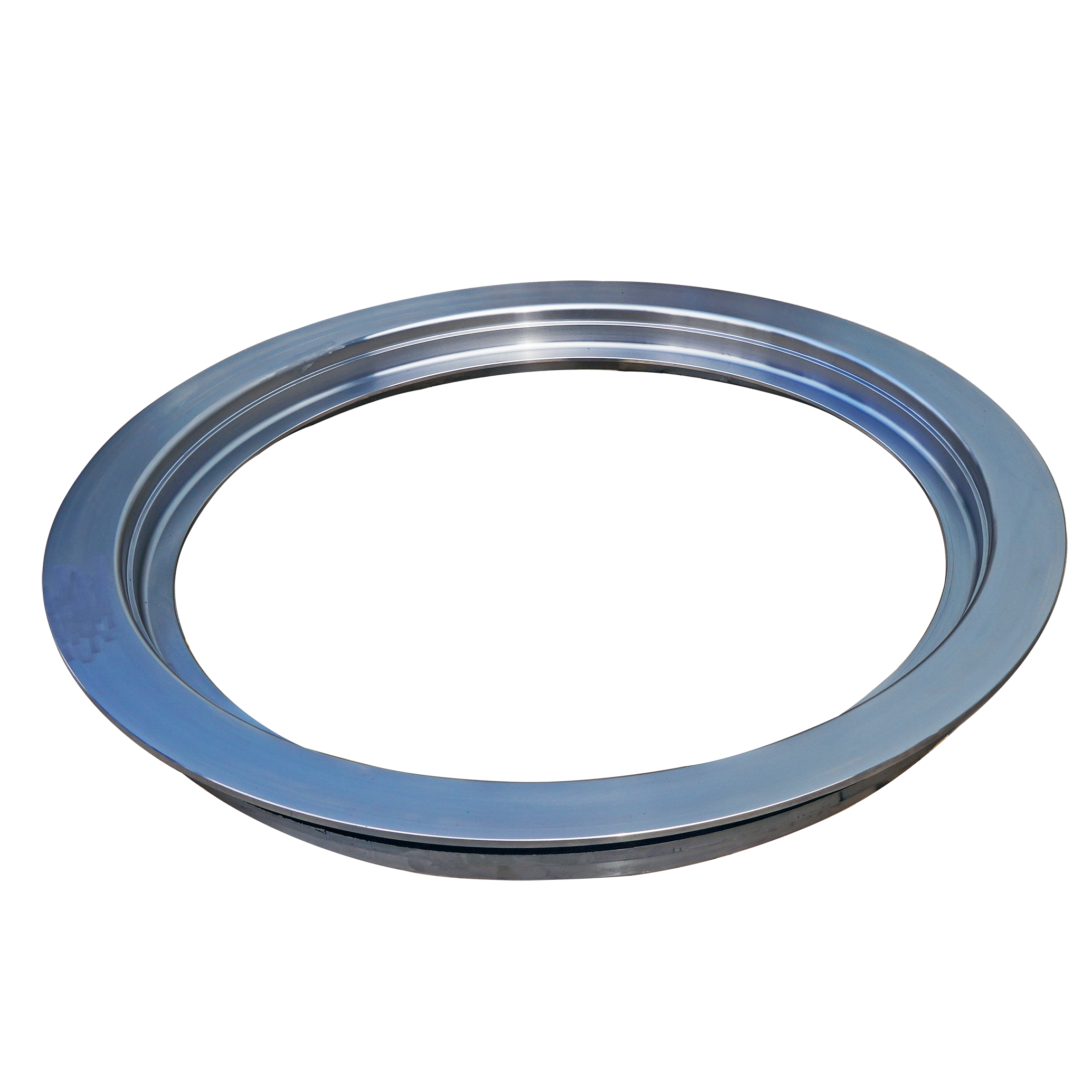

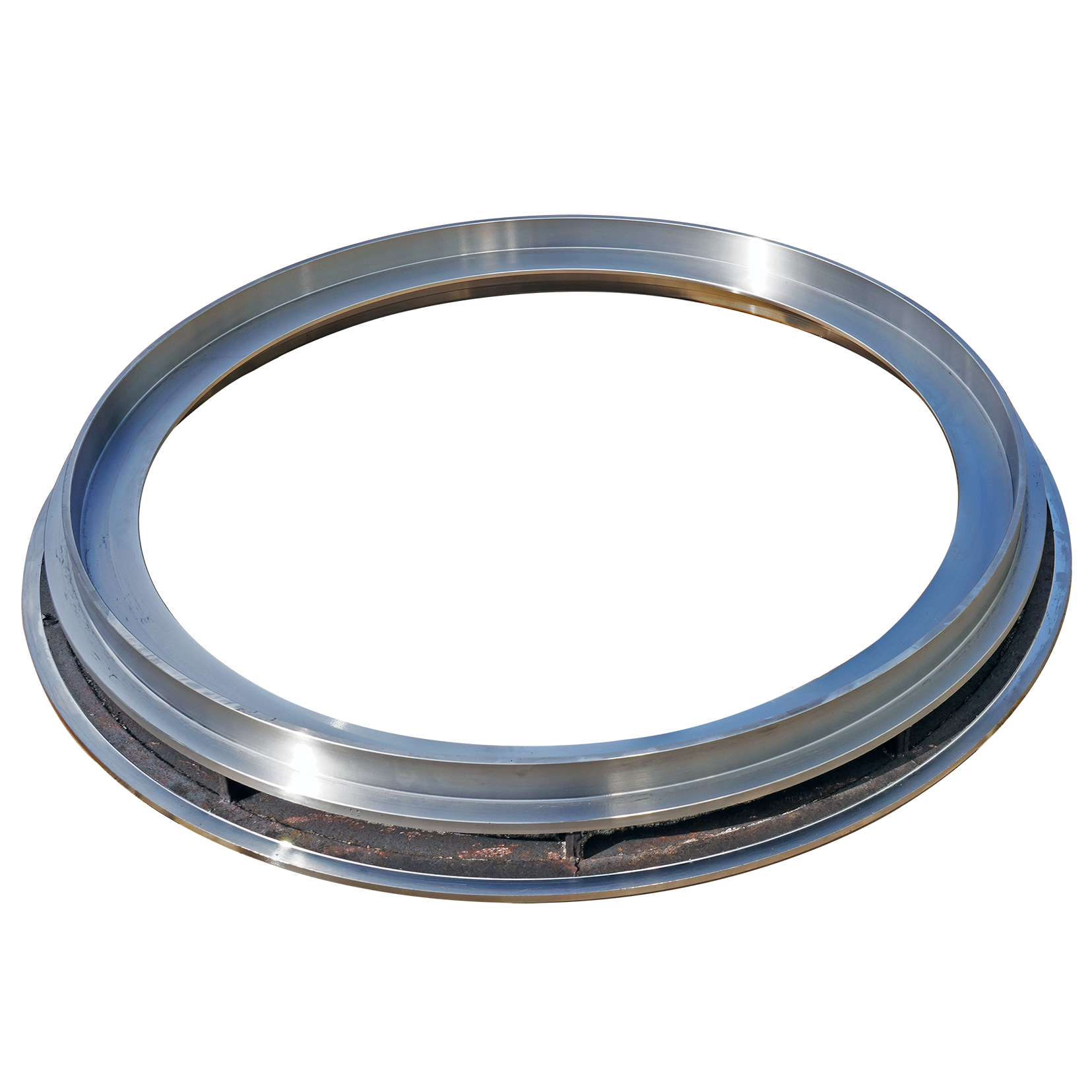

fuel heat exchanger

In the world of industrial engineering and thermal dynamics, the fuel heat exchanger is a pivotal component that merits the highest consideration. Serving as a critical functionary in systems requiring the precise transfer of heat from fuel to other fluids, the fuel heat exchanger plays an essential role in optimizing energy efficiency and operational sustainability.

From a manufacturer's perspective, reliability and quality assurance processes are embedded into every stage of producing these exchangers. Calibration, rigorous testing, and real-world simulations form the backbone of trustworthiness in every product that rolls out of production lines. Adherence to international standards, such as ASME or SAE specifications, further vouches for the engineering precision and safe applicability of these components across various domains. Embracing innovation, modern fuel heat exchangers often incorporate advanced technologies like additive manufacturing, which allows complex geometric formations not feasible with traditional manufacturing techniques. This advance not only results in lighter and more efficient designs but also facilitates rapid prototyping and customization to meet specific industry requirements. In terms of experience, one cannot overlook the feedback loop between users and engineers. Service operators who utilize these exchangers in challenging environments offer invaluable insights that drive continuous improvements, contributing to product evolution and the setting of higher benchmarks in heat exchange technology. Trust in fuel heat exchanger technology is built upon certified performance and dependable operation, qualities that are non-negotiable in high-stakes fields. Procurement decisions often lean heavily on the proven historical reliability and return on investment these components offer, underscoring their reputability. Consequently, operators and engineers align in advocating for robust maintenance practices and diagnostic checks to ensure longevity and robust functionality over operational years. Overall, the fuel heat exchanger embodies a harmonious amalgamation of expert knowledge, authoritative design, reliability, and dynamic user experience, proving its indispensable value. Beyond its technical merits, the quest for energy conservation and efficiency continues to propel its development, making it an essential topic within the landscape of modern engineering solutions.

From a manufacturer's perspective, reliability and quality assurance processes are embedded into every stage of producing these exchangers. Calibration, rigorous testing, and real-world simulations form the backbone of trustworthiness in every product that rolls out of production lines. Adherence to international standards, such as ASME or SAE specifications, further vouches for the engineering precision and safe applicability of these components across various domains. Embracing innovation, modern fuel heat exchangers often incorporate advanced technologies like additive manufacturing, which allows complex geometric formations not feasible with traditional manufacturing techniques. This advance not only results in lighter and more efficient designs but also facilitates rapid prototyping and customization to meet specific industry requirements. In terms of experience, one cannot overlook the feedback loop between users and engineers. Service operators who utilize these exchangers in challenging environments offer invaluable insights that drive continuous improvements, contributing to product evolution and the setting of higher benchmarks in heat exchange technology. Trust in fuel heat exchanger technology is built upon certified performance and dependable operation, qualities that are non-negotiable in high-stakes fields. Procurement decisions often lean heavily on the proven historical reliability and return on investment these components offer, underscoring their reputability. Consequently, operators and engineers align in advocating for robust maintenance practices and diagnostic checks to ensure longevity and robust functionality over operational years. Overall, the fuel heat exchanger embodies a harmonious amalgamation of expert knowledge, authoritative design, reliability, and dynamic user experience, proving its indispensable value. Beyond its technical merits, the quest for energy conservation and efficiency continues to propel its development, making it an essential topic within the landscape of modern engineering solutions.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025