Úno . 14, 2025 23:08 Back to list

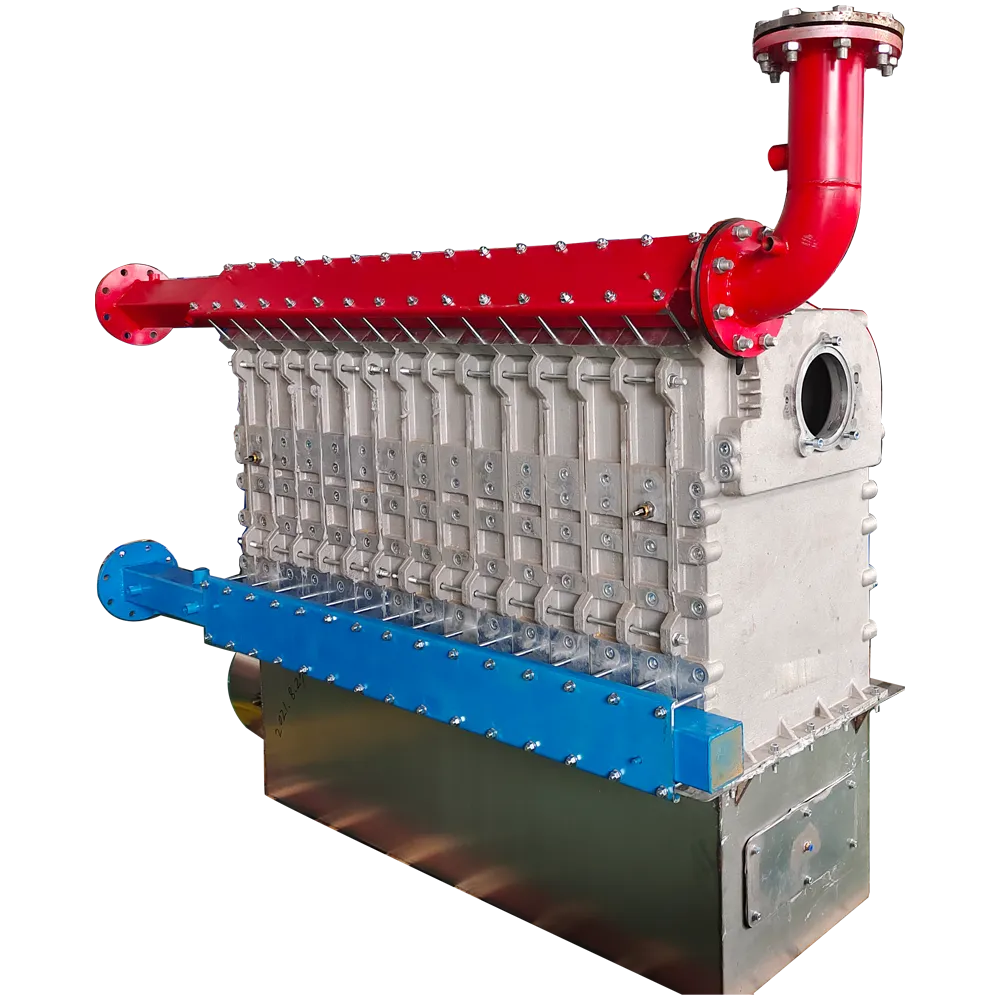

hex heat exchanger

Hex heat exchangers have emerged as a cornerstone technology in industries requiring efficient thermal management. As a mechanical device designed for maximizing heat transfer between two or more fluids, these exchangers offer versatility and profound efficiency gains. Let’s delve into the expertise and authoritativeness of these remarkable devices, understanding their design, operational benefits, and how they stand as an authoritative choice in thermal systems.

User experience with hex heat exchangers further underscores their trustworthiness. Many industry professionals report extended operational periods without performance degradation—a critical factor in maintaining uninterrupted production lines. The ease of installation and flexibility in integration into existing systems make them a go-to solution for engineers and plant managers striving for minimal disruption and maximum uptime. Trust in hex heat exchangers is additionally reinforced by certified compliance with international industry standards, such as ISO and ASME. These certifications denote a benchmark of quality and safety, assuring stakeholders of their investment’s reliability. Moreover, leading manufacturers offer comprehensive warranties and customer support, elevating user confidence in both product and brand. As industries evolve, the demand for innovative heat management solutions grows. Hex heat exchangers are at the forefront of meeting these demands through continuous technological advancements. Whether it’s their role in pioneering renewable energy cooling systems or improving the efficiency of traditional fossil fuel operations, their future is intertwined with progress in energy technology. To maintain authoritative status, manufacturers invest in research and development, pushing the boundaries of what hex heat exchangers can achieve. Collaborations with research institutions and feedback from field engineers drive innovation, ensuring that new iterations of these devices continue to meet the ever-increasing demands of modern applications. In conclusion, the authoritative edge hex heat exchangers provide is undisputed. Their intricate design, backed by expert engineering and industry credibility, assures their place in the competitive landscape of heat exchange technology. They embody a perfect amalgamation of tradition and innovation, ensuring they remain an essential tool in industries worldwide seeking effective thermal management solutions.

User experience with hex heat exchangers further underscores their trustworthiness. Many industry professionals report extended operational periods without performance degradation—a critical factor in maintaining uninterrupted production lines. The ease of installation and flexibility in integration into existing systems make them a go-to solution for engineers and plant managers striving for minimal disruption and maximum uptime. Trust in hex heat exchangers is additionally reinforced by certified compliance with international industry standards, such as ISO and ASME. These certifications denote a benchmark of quality and safety, assuring stakeholders of their investment’s reliability. Moreover, leading manufacturers offer comprehensive warranties and customer support, elevating user confidence in both product and brand. As industries evolve, the demand for innovative heat management solutions grows. Hex heat exchangers are at the forefront of meeting these demands through continuous technological advancements. Whether it’s their role in pioneering renewable energy cooling systems or improving the efficiency of traditional fossil fuel operations, their future is intertwined with progress in energy technology. To maintain authoritative status, manufacturers invest in research and development, pushing the boundaries of what hex heat exchangers can achieve. Collaborations with research institutions and feedback from field engineers drive innovation, ensuring that new iterations of these devices continue to meet the ever-increasing demands of modern applications. In conclusion, the authoritative edge hex heat exchangers provide is undisputed. Their intricate design, backed by expert engineering and industry credibility, assures their place in the competitive landscape of heat exchange technology. They embody a perfect amalgamation of tradition and innovation, ensuring they remain an essential tool in industries worldwide seeking effective thermal management solutions.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025