Pro . 15, 2024 22:09 Back to list

milling frame casting factories

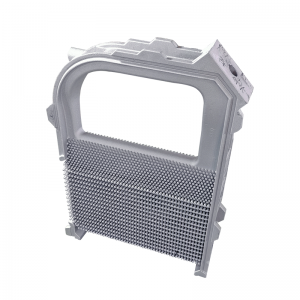

The Evolution of Milling Frame Casting Factories A Focus on Efficiency and Quality

Milling frame casting factories play a crucial role in the manufacturing sector, providing essential components for various machinery and equipment used in multiple industries. The process of casting milling frames involves pouring molten metal into a mold to create a specific shape, which is critical in supporting the performance and durability of machines. This article explores the evolution and significance of milling frame casting factories, emphasizing the importance of efficiency and quality in production.

Historically, metal casting can be traced back thousands of years, evolving from simple techniques to complex processes that we see in modern factories. In the early days, artisans would manually shape and mold metal, but as industrialization took hold, especially during the 19th and 20th centuries, the mass production of metal components became feasible. This shift paved the way for specialized casting factories to emerge, particularly those focused on producing milling frames.

One of the primary advantages of casting over other manufacturing processes is its ability to create intricate shapes and designs that would be difficult or impossible to achieve with machining alone. Milling frames, which serve as the backbone of milling machines, require durability and precision. Therefore, modern milling frame casting factories have invested heavily in technology and machinery to improve their capabilities.

Today, advanced casting techniques such as sand casting, investment casting, and die casting are widely employed. Sand casting is particularly popular due to its flexibility and cost-effectiveness, allowing manufacturers to produce complex designs while maintaining high standards of quality. Investment casting, on the other hand, provides superior surface finish and dimensional accuracy, making it ideal for high-end applications where precision is critical.

milling frame casting factories

In addition to technological advancements, the optimization of production processes has become a focal point for milling frame casting factories. The implementation of lean manufacturing principles, which emphasize waste reduction and efficiency, has transformed how these factories operate. By streamlining workflows and enhancing communication among departments, factories can significantly reduce lead times while increasing output.

Quality control is another essential aspect of milling frame casting factories. With the growing demand for reliable machinery across various sectors, factories must adhere to stringent quality standards. This is achieved through rigorous testing and inspection processes, ensuring that each milling frame meets or exceeds industry standards. Various methods, including non-destructive testing and metallurgical analysis, are utilized to assess the integrity of cast components before they are dispatched for assembly.

Moreover, the rise of automation and Industry 4.0 has influenced the casting process. Smart factories, equipped with IoT devices and predictive analytics, can monitor casting operations in real time. This capability allows for quick adjustments to be made, ensuring optimal conditions for casting and improving overall product quality. The integration of robotics also enhances precision and consistency in tasks such as mold handling and finishing operations.

Sustainability is becoming increasingly important in the manufacturing sector, and milling frame casting factories are no exception. Many factories are now adopting eco-friendly practices, such as recycling scrap metal and utilizing energy-efficient technologies. This commitment to sustainability not only benefits the environment but also aligns with consumer preferences for green manufacturing practices.

In conclusion, milling frame casting factories are vital to the manufacturing landscape, providing essential components that sustain various industries. The evolution of these factories—shaped by advancements in technology, process optimization, and a commitment to quality—has led to enhanced efficiency and product reliability. As the industry continues to evolve, milling frame casting factories will remain at the forefront of innovation, meeting the growing demands of an ever-changing market while emphasizing sustainability and efficiency. Their ability to adapt and thrive will ultimately determine their significance in the global manufacturing supply chain.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025