Ion . 16, 2025 04:20 Back to list

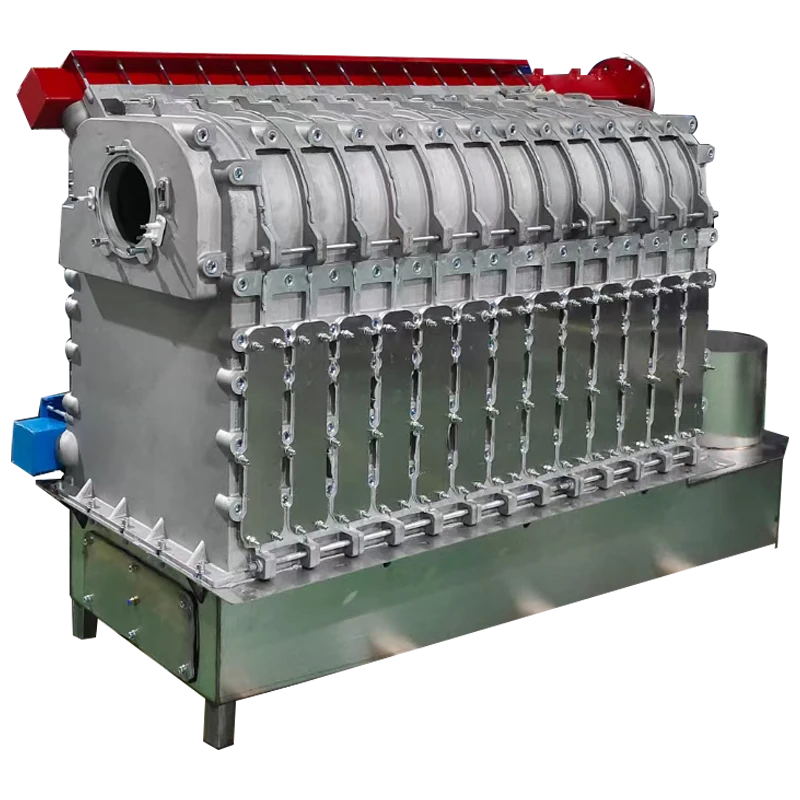

Cast Aluminum-Silicon Alloy Radiator/ Exchanger for Natural Gas Fired Boiler

Cast iron parts have earned a respected place in the manufacturing and industrial sectors due to their durability, strength, and versatility. As someone deeply embedded in the industry, the nuances of crafting and utilizing cast iron components bring a depth of appreciation that can only be understood through experience and expertise.

The volatility in supply chain dynamics today demands resilience, which cast iron manufacturers are uniquely positioned to offer. With its abundant raw material sources and recyclable nature, cast iron aligns with sustainable manufacturing practices, addressing environmental concerns increasingly emphasized by consumers and regulatory bodies. The choice of cast iron parts thus ensures longevity and sustainability, key factors that conscientious businesses consider. Meanwhile, trustworthiness in this field is non-negotiable. Quality assurance in cast iron manufacturing is prioritized through rigorous testing protocols. Each batch of parts undergoes tensile, compression, and fatigue testing, certified by international standards that validate their capability to meet and exceed industry requirements. Customers can rely on our parts not only for their structural strength but also for the integrity that comes with certified production processes. In conclusion, the use of cast iron parts presents a trifecta of durability, sustainability, and cost-effectiveness. Drawing on vast industry expertise, our products are designed to meet diverse applications across industries, backed by a commitment to quality and innovation. With a solid foundation of trust and authority, we continue to lead in a field where precision and reliability are the benchmarks of success.

The volatility in supply chain dynamics today demands resilience, which cast iron manufacturers are uniquely positioned to offer. With its abundant raw material sources and recyclable nature, cast iron aligns with sustainable manufacturing practices, addressing environmental concerns increasingly emphasized by consumers and regulatory bodies. The choice of cast iron parts thus ensures longevity and sustainability, key factors that conscientious businesses consider. Meanwhile, trustworthiness in this field is non-negotiable. Quality assurance in cast iron manufacturing is prioritized through rigorous testing protocols. Each batch of parts undergoes tensile, compression, and fatigue testing, certified by international standards that validate their capability to meet and exceed industry requirements. Customers can rely on our parts not only for their structural strength but also for the integrity that comes with certified production processes. In conclusion, the use of cast iron parts presents a trifecta of durability, sustainability, and cost-effectiveness. Drawing on vast industry expertise, our products are designed to meet diverse applications across industries, backed by a commitment to quality and innovation. With a solid foundation of trust and authority, we continue to lead in a field where precision and reliability are the benchmarks of success.

Share

Pervious:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025