Rhag . 22, 2024 00:50 Back to list

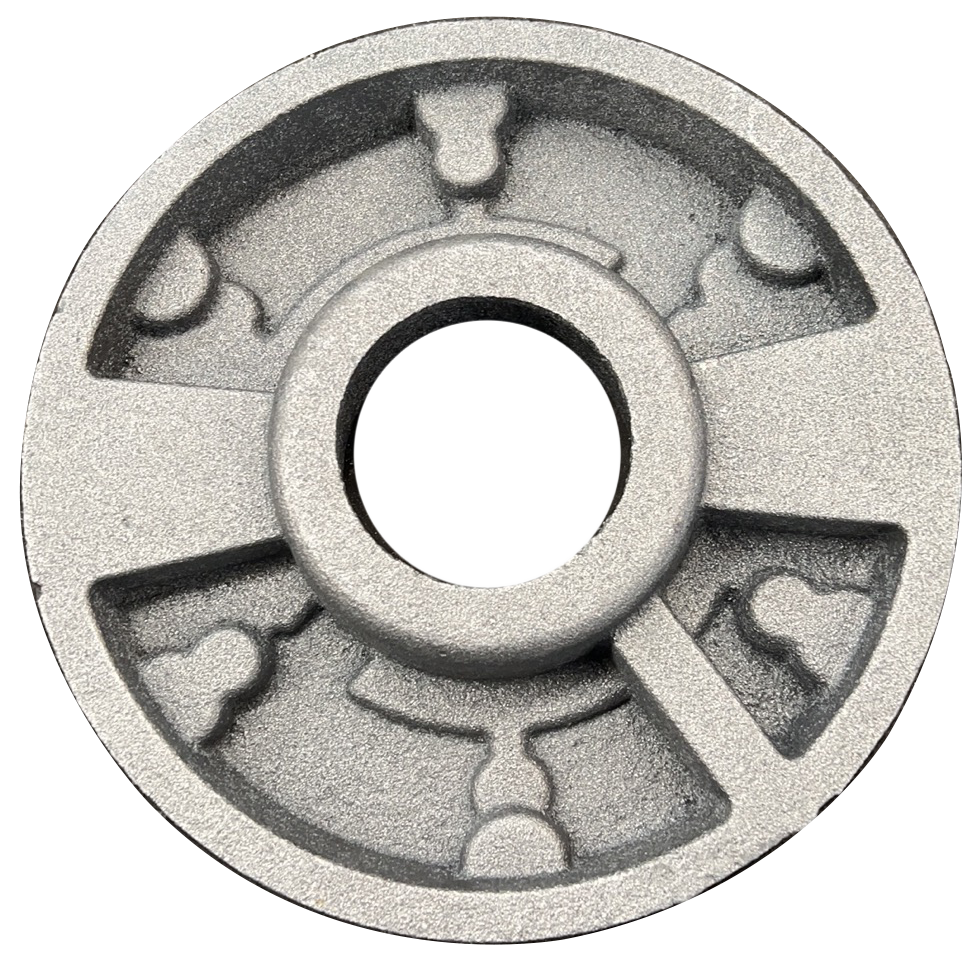

custom gravity casting

Custom Gravity Casting A Comprehensive Overview

Gravity casting is a manufacturing process that utilizes the force of gravity to fill a mold with liquid metal. This method is widely used in various industries due to its efficiency and cost-effectiveness. Among the different types of casting processes, custom gravity casting has gained significant traction, offering tailored solutions for specific applications. In this article, we will explore the concept of custom gravity casting, its advantages, applications, and the factors to consider when opting for this method.

What is Custom Gravity Casting?

Custom gravity casting involves creating molds that are specifically designed to meet the unique specifications of a particular project or client. Unlike standard casting, where pre-existing molds are used, custom gravity casting focuses on producing one-of-a-kind components that require precision and attention to detail. The process involves pouring molten metal into a mold, where it cools and solidifies, taking on the shape of the mold.

The primary materials used in custom gravity casting include various alloys of aluminum, zinc, and magnesium. These materials are chosen for their favorable properties, such as lightweight, durability, and excellent mechanical strength. The adaptability of gravity casting allows for intricate designs and complex geometries, making it suitable for a diverse range of applications.

Advantages of Custom Gravity Casting

1. High Precision One of the key benefits of custom gravity casting is its ability to produce highly accurate and precise components. The process minimizes defects and ensures tight tolerances, which is crucial for industries where precision is paramount.

2. Cost-Effective for Low to Medium Volumes While traditional die casting can be expensive due to high upfront costs, custom gravity casting is more economical for producing low to medium volumes. The cost of creating custom molds is often offset by the benefits of reduced material waste and improved production efficiency.

3. Versatility Custom gravity casting can accommodate a wide range of metals and alloys, enabling manufacturers to select the most suitable material for their specific application. This versatility extends to the design capabilities, allowing for complex shapes that may be challenging to achieve through other manufacturing processes.

4. Reduced Machining Requirements Components produced through custom gravity casting often require less post-processing, such as machining and finishing. This further reduces costs and shortens lead times, making it an attractive option for many manufacturers.

Applications of Custom Gravity Casting

custom gravity casting

Custom gravity casting finds applications across various industries, including

- Aerospace Customized components for aircraft and spacecraft, where precision and weight savings are critical. - Automotive Engine blocks, transmission housings, and other structural components that demand high strength and low weight. - Medical Devices Producing specific parts for medical equipment, ensuring compliance with stringent industry standards. - Electronics Housing for electronic components and devices, which often require intricate designs and efficient cooling solutions.

Factors to Consider

When opting for custom gravity casting, several factors should be considered

1. Material Selection Choosing the right material is essential. Different metals and alloys have distinct properties that can affect the performance of the final product.

2. Design Complexity The intricacy of the designs can impact the mold-making process and the overall cost. It’s important to strike a balance between design requirements and manufacturability.

3. Production Volume Assessing the expected production volume is crucial. Custom gravity casting is ideal for low to medium volumes, while high-volume production may benefit from different casting methods.

4. Supplier Expertise Selecting a casting supplier with experience in custom gravity casting can significantly impact the quality and success of the project. Look for suppliers with a proven track record and the ability to collaborate on design optimization.

Conclusion

Custom gravity casting is a valuable solution for industries seeking customized components that require high precision and efficiency. By understanding its advantages and applications, manufacturers can make informed decisions to enhance their production processes. As technology advances, custom gravity casting is likely to play an increasingly significant role in the manufacturing landscape, providing innovative solutions to meet the evolving needs of various sectors.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025