Rhag . 27, 2024 18:42 Back to list

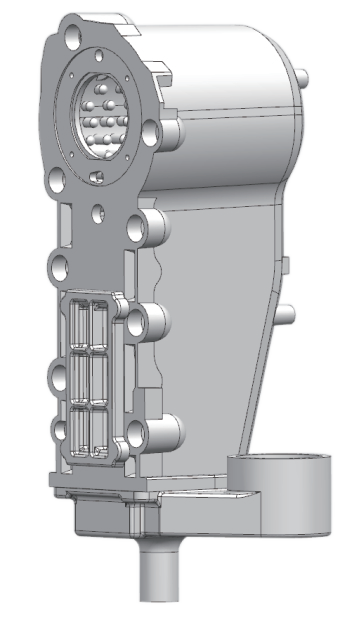

refrigeration shell and tube condenser

Understanding Refrigeration Shell and Tube Condenser

Refrigeration systems are an essential part of modern life, providing essential cooling solutions for domestic, commercial, and industrial applications. Among the many components that make up these systems, the shell and tube condenser plays a crucial role in the refrigeration cycle, enhancing heat exchange efficiency and ensuring optimal performance. This article will explore the design, operation, advantages, and applications of shell and tube condensers in refrigeration systems.

Design and Structure

A shell and tube condenser consists of a series of tubes housed within a cylindrical shell. Typically, one fluid flows through the tubes while another fluid, usually cooling water, circulates around the outside of the tubes within the shell. The primary function of the condenser is to remove heat from the refrigerant vapor, allowing it to condense into a liquid state as it loses heat to the cooling medium. This process effectively converts the high-pressure vapor back into a cooler liquid, ready to re-enter the refrigeration cycle.

The design of these condensers can vary significantly based on the specific applications and requirements. The arrangement of tubes can be either in a single pass or multi-pass configuration, which determines how efficiently heat transfer occurs. Additionally, factors such as the tube material, diameter, and surface area are chosen based on the properties of the fluids involved and the operational temperature and pressure conditions.

Operational Principles

The operation of a shell and tube condenser can be understood through the principles of heat transfer and fluid dynamics. When the refrigerant vapor enters the condenser, it is at a high temperature and low pressure. As it flows through the tubes, it encounters a cooler fluid (typically water or another cooling medium) flowing in the opposite direction. This counterflow arrangement maximizes the temperature gradient between the two fluids, enhancing the efficiency of heat transfer.

As the refrigerant vapor loses heat to the cooling water, it begins to condense. During this phase change, the vapor releases latent heat, which is absorbed by the cooling water. The cooler water, in turn, exits the shell at a higher temperature, effectively transferring heat away from the system. The efficiency of this heat exchange process is critical for maintaining the overall performance of the refrigeration system.

Advantages of Shell and Tube Condensers

refrigeration shell and tube condenser

Shell and tube condensers offer a multitude of advantages that make them a popular choice in various refrigeration applications. Some of these benefits include

1. High Efficiency Their design allows for excellent heat exchange rates, leading to efficient cooling performance, which is essential in maintaining desired temperature levels in refrigeration systems.

2. Versatility Shell and tube condensers can be tailored for various applications, accommodating different fluids, flow rates, and operational conditions. This versatility makes them suitable for everything from small refrigeration units to large industrial systems.

3. Ease of Maintenance Accessing and cleaning the tubes in shell and tube condensers is relatively straightforward, facilitating regular maintenance and service. Tube bundles can be easily removed for thorough cleaning, which is vital for maintaining efficiency.

4. Robust Design Constructed with durable materials that withstand high pressures and temperatures, these condensers can operate reliably in demanding environments.

Applications

Shell and tube condensers are widely used across different sectors. In the food and beverage industry, they are crucial in processes like milk pasteurization and beer production, where efficient heat exchange is vital. They are also commonly found in HVAC applications, industrial refrigeration, power plants, chemical processing, and oil refineries, highlighting their critical role in various cooling and condensing processes.

Conclusion

The shell and tube condenser represents a cornerstone technology in refrigeration systems, combining effective heat transfer with robust and versatile design. By understanding their operation and advantages, engineers and technicians can ensure that refrigeration systems operate efficiently and reliably, ultimately contributing to energy savings and operational efficacy. As industries continue to evolve and demand for effective cooling solutions grows, the importance of shell and tube condensers will undoubtedly persist in supporting these advancements.

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025