Rhag . 12, 2024 11:12 Back to list

Top Manufacturers of SG Iron Castings for Optimal Performance and Durability

The Rise of SG Iron Casting Manufacturers

Spheroidal Graphite (SG) Iron, also known as ductile iron, has gained significant traction in various industrial applications due to its unique properties such as high strength, excellent corrosion resistance, and remarkable machinability. As industries strive for efficiency and durability in their products, SG iron casting manufacturers have become indispensable players in the manufacturing landscape.

Understanding SG Iron

SG iron is characterized by its microstructure, which consists of graphite nodules. These nodules differentiate SG iron from traditional cast iron and allow it to exhibit performance traits similar to that of steel, yet at a lower cost. Its combination of toughness, wear resistance, and enhanced mechanical properties makes it an ideal choice for components used in automotive, construction, and heavy machinery industries.

Growth in Demand

The demand for SG iron castings has surged in recent years, primarily driven by the automotive industry, where components such as crankshafts, gears, and suspension parts require materials that can endure high stress and strain. The construction sector also relies heavily on SG iron for producing pipes, valves, and fittings that must withstand significant pressure and corrosion.

With the growing need for sustainable materials, manufacturers are also focusing on recycling and reusing ferrous materials. SG iron casting manufacturers are exploring innovative ways to improve their processes to minimize waste and reduce the carbon footprint associated with production. This commitment to sustainability not only helps in preserving the environment but also aligns with the global trend toward eco-friendly practices in manufacturing.

Advancements in Technology

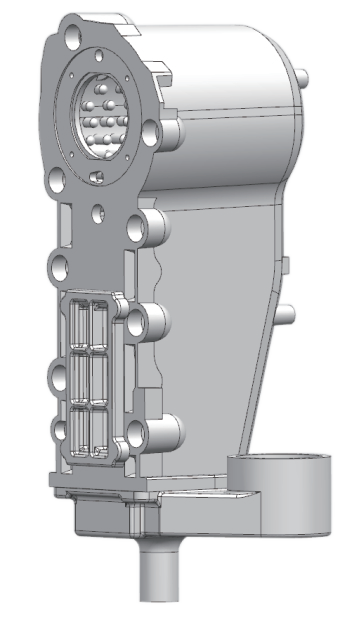

sg iron casting manufacturers

One of the key factors contributing to the growth of SG iron casting manufacturers is technological advancement. Modern foundries are increasingly adopting state-of-the-art technologies such as computer-aided design (CAD), simulation software, and advanced casting methods like sand casting and investment casting. These technologies enhance precision and efficiency, allowing manufacturers to produce complex geometries with less material waste.

Furthermore, advancements in melting and pouring techniques ensure that the properties of SG iron are consistently maintained, leading to higher quality casting products. Quality control measures, including metallurgical testing and non-destructive testing methods, are now integral to the production process, allowing manufacturers to meet the stringent requirements of various industries.

Challenges Faced by Manufacturers

While the future looks promising for SG iron casting manufacturers, several challenges cannot be overlooked. The volatility of raw material prices, especially for alloys used in the production of ductile iron, is a concern that affects profitability. Moreover, the workforce in this sector must adapt to the rapid technological changes and increasingly complex projects calling for skilled labor.

Manufacturers must also navigate the regulatory landscape related to environmental concerns, safety standards, and quality certifications, which can impose additional costs and affect competitiveness. The ability to stay agile and respond to market demands while upholding these standards is crucial for long-term success.

Conclusion

In conclusion, SG iron casting manufacturers are vital contributors to the manufacturing sector, providing essential materials that meet the durability and performance requirements of various applications. As industries continue to evolve, the role of these manufacturers will expand, driven by advancements in technology and an increasing focus on sustainability. Addressing the challenges they face will be crucial in maintaining their position in a competitive market. With innovation at the forefront, SG iron casting manufacturers are poised to play a significant role in shaping the future of materials engineering.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025