feb . 11, 2025 01:17 Back to list

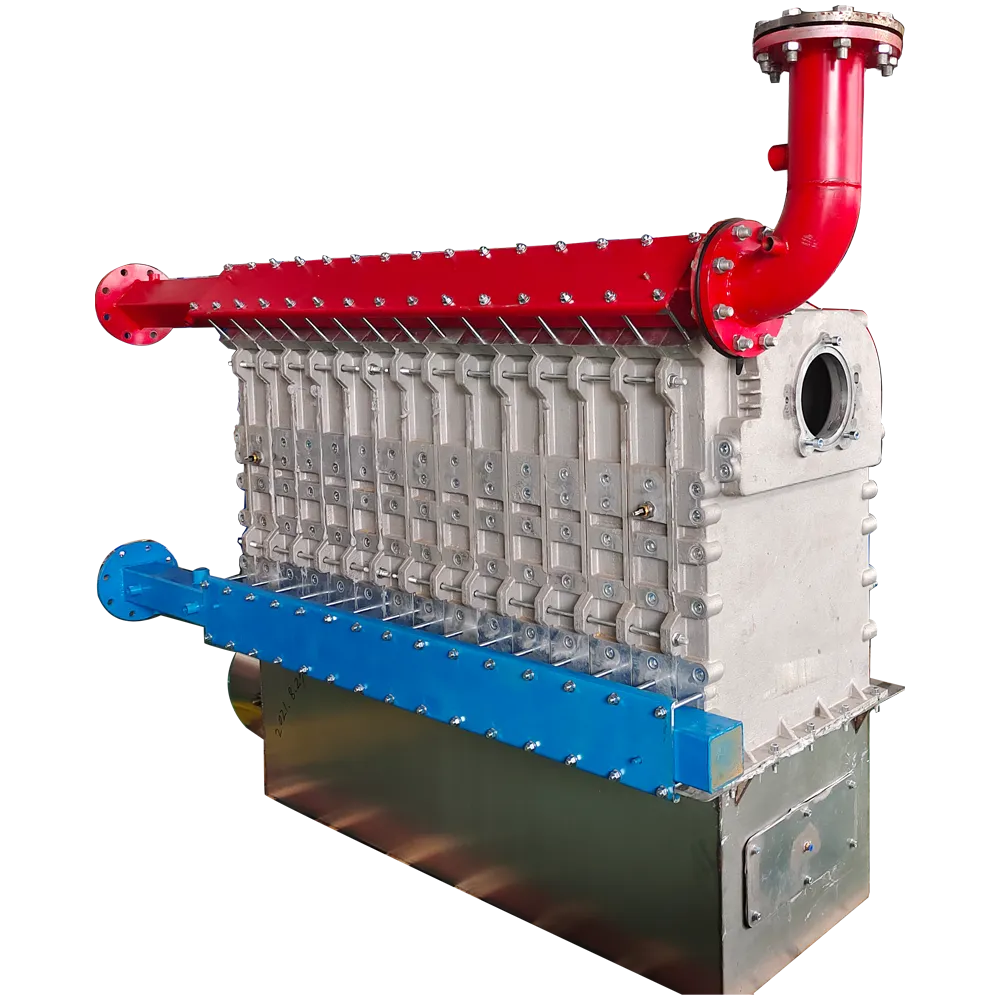

miniature heat exchangers

Miniature heat exchangers are rapidly transforming industries where efficiency, space, and performance are paramount. These compact, powerful devices play a critical role in a myriad of applications, from electronics cooling to automotive systems, each demanding seamless thermal management. This article delves into the intricacies that make miniature heat exchangers not just a choice, but a necessity, and why they are becoming the cornerstone of modern engineering solutions.

An emphasis on authority and trustworthiness in the development of miniature heat exchangers is evident in the collaborative efforts between universities, research institutions, and leading industry players. These partnerships work to push the boundaries of thermal management technologies, focusing on sustainability and efficiency. With energy efficiency becoming a global focus, the role of experts in advancing miniature heat exchanger technology is undisputed, continually setting new benchmarks for performance. The design of miniature heat exchangers is subject to rigorous testing and quality assurance protocols. Trust in these devices is built on the meticulous standards set by governing bodies and industry certifications, ensuring that each unit meets or exceeds the thermal management requirements of its intended application. This rigorous quality control fosters confidence among engineers and designers who rely on these components to function flawlessly in mission-critical applications. Experience from users of these heat exchangers highlights their versatility and dependability. Industries report extended equipment life, reduced energy costs, and greater overall system efficiency, attributing these benefits to the refined performance of miniature heat exchangers. As they are integrated into more systems, real-world feedback continues to inform enhancements, leading to even more reliable designs and applications. In conclusion, miniature heat exchangers are redefining the landscape of thermal management across various industries. Their contribution to efficiency, space-saving, and performance is unparalleled, driven by expert knowledge, authoritative design, and trusted manufacturing practices. As technology continues to advance, the role of miniature heat exchangers will evolve, meeting new challenges with the same ingenuity and reliability they have consistently delivered.

An emphasis on authority and trustworthiness in the development of miniature heat exchangers is evident in the collaborative efforts between universities, research institutions, and leading industry players. These partnerships work to push the boundaries of thermal management technologies, focusing on sustainability and efficiency. With energy efficiency becoming a global focus, the role of experts in advancing miniature heat exchanger technology is undisputed, continually setting new benchmarks for performance. The design of miniature heat exchangers is subject to rigorous testing and quality assurance protocols. Trust in these devices is built on the meticulous standards set by governing bodies and industry certifications, ensuring that each unit meets or exceeds the thermal management requirements of its intended application. This rigorous quality control fosters confidence among engineers and designers who rely on these components to function flawlessly in mission-critical applications. Experience from users of these heat exchangers highlights their versatility and dependability. Industries report extended equipment life, reduced energy costs, and greater overall system efficiency, attributing these benefits to the refined performance of miniature heat exchangers. As they are integrated into more systems, real-world feedback continues to inform enhancements, leading to even more reliable designs and applications. In conclusion, miniature heat exchangers are redefining the landscape of thermal management across various industries. Their contribution to efficiency, space-saving, and performance is unparalleled, driven by expert knowledge, authoritative design, and trusted manufacturing practices. As technology continues to advance, the role of miniature heat exchangers will evolve, meeting new challenges with the same ingenuity and reliability they have consistently delivered.

Share

Pervious:

Latest news

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025