Dez . 11, 2024 22:53 Back to list

fibre reinforced concrete pipe mould bottom ring suppliers

Understanding Fiber Reinforced Concrete Pipe Moulds and the Role of Suppliers

Fiber reinforced concrete (FRC) has emerged as a revolutionary material in the construction industry, offering enhanced performance characteristics compared to traditional concrete. Among its many applications, FRC is particularly valuable in the production of pipes, especially for infrastructure projects. In this context, the importance of high-quality pipe moulds, including bottom rings, cannot be understated. This article explores the significance of fiber reinforced concrete pipe moulds, the role of bottom rings, and the criteria for selecting reliable suppliers.

The Foundation of Fiber Reinforced Concrete

Fiber reinforced concrete incorporates various types of fibers into the concrete mix to improve its mechanical properties. The fibers used can be made from materials such as steel, glass, synthetic, or natural fibers. This reinforcement helps to address common issues associated with traditional concrete, such as brittle behavior and susceptibility to cracking. The incorporation of fibers enhances the tensile strength, impact resistance, and durability of the finished product.

In the context of pipe manufacturing, the use of FRC allows for the production of pipes that can withstand harsh environmental conditions, including high pressure and varying temperatures. These pipes are essential for various applications, including sewage systems, stormwater management, and even potable water supply. The quality of the pipes significantly depends on the precision of the moulds used during manufacturing.

The Role of Pipe Moulds and Bottom Rings

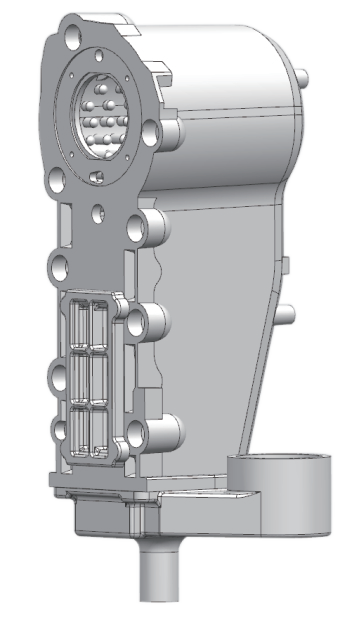

Pipe moulds play a critical role in achieving the desired shape, size, and surface finish of the concrete pipes. Different components of the mould, such as the bottom ring, contribute to the overall structure and integrity of the pipe. The bottom ring is particularly essential as it supports the weight of the pipe during curing and provides stability during the production process.

High-quality bottom rings are typically designed to prevent deformation during the concrete pouring and curing stages. They are constructed to withstand the stresses associated with the weight of the concrete and maintain the shape of the pipe. The design of the bottom ring must accommodate the specific requirements of the end product, including the diameter, wall thickness, and any additional reinforcement needed.

Importance of Selecting Reliable Suppliers

Choosing the right supplier for fiber reinforced concrete pipe moulds, particularly bottom rings, is vital for ensuring the quality of the final product. Here are several key factors to consider when selecting a supplier

fibre reinforced concrete pipe mould bottom ring suppliers

1. Experience and Expertise Suppliers with extensive experience in the industry are more likely to understand the nuances of producing high-quality moulds. Their expertise will be reflected in the quality of their products and customer service.

2. Quality Assurance Look for suppliers who implement rigorous quality control processes. They should provide certifications and documentation to demonstrate that their moulds meet industry standards.

3. Customization Options Every project has unique requirements. A reliable supplier should offer customization options for their moulds, including variations in size, design, and material composition.

4. Material Quality The durability and performance of the bottom rings depend largely on the materials used. Suppliers should offer moulds made from high-quality, robust materials that can withstand the rigors of the manufacturing process.

5. Reputation and Reviews Research the supplier’s reputation within the industry. Customer testimonials and reviews can provide valuable insights into their reliability and the quality of their products.

6. Technical Support After-sales support is crucial. A good supplier should offer technical assistance and guidance during installation and usage.

7. Cost-Effectiveness While it is important to consider costs, choosing the cheapest option might result in compromised quality. Instead, look for a balance between quality and price to ensure long-term benefits.

Conclusion

Fiber reinforced concrete pipe moulds, especially bottom rings, are fundamental components in producing high-quality concrete pipes. The choice of suppliers is equally critical, as it impacts the overall effectiveness and durability of the pipes produced. By focusing on the outlined criteria, construction companies and manufacturers can ensure that they source the best materials for their projects, leading to enhanced structural performance and longevity in infrastructure applications. As the demand for FRC increases, the importance of reliable suppliers will only continue to grow, driving innovation and quality in the construction industry.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025