Οκτ . 06, 2024 06:05 Back to list

bell and spigot ductile iron pipe

Understanding Bell and Spigot Ductile Iron Pipe A Durable Solution for Water Distribution

Bell and spigot ductile iron pipes have become a cornerstone in modern water distribution systems, owing to their impressive durability and adaptability. As communities continue to grow, the demand for reliable piping systems has heightened, making ductile iron pipes an increasingly popular choice among engineers and planners.

Ductile iron, an alloyed form of cast iron, boasts superior strength and flexibility compared to traditional cast iron. This makes it particularly suitable for applications involving water transportation, sewage systems, and industrial applications where high pressure is common. The bell and spigot joint system is a standard configuration that allows for easy assembly and disassembly, which is crucial for maintenance and repairs.

One of the primary advantages of bell and spigot ductile iron pipes is their resistance to corrosion. Traditionally, cast iron pipes were susceptible to rust and degradation over time, leading to leaks and system failures. However, ductile iron pipes can be coated with various protective layers, including cement mortar lining, epoxy, and other protective coatings, significantly enhancing their lifespan. This resistance not only extends the life of the pipes but also reduces maintenance costs and the need for frequent replacements.

bell and spigot ductile iron pipe

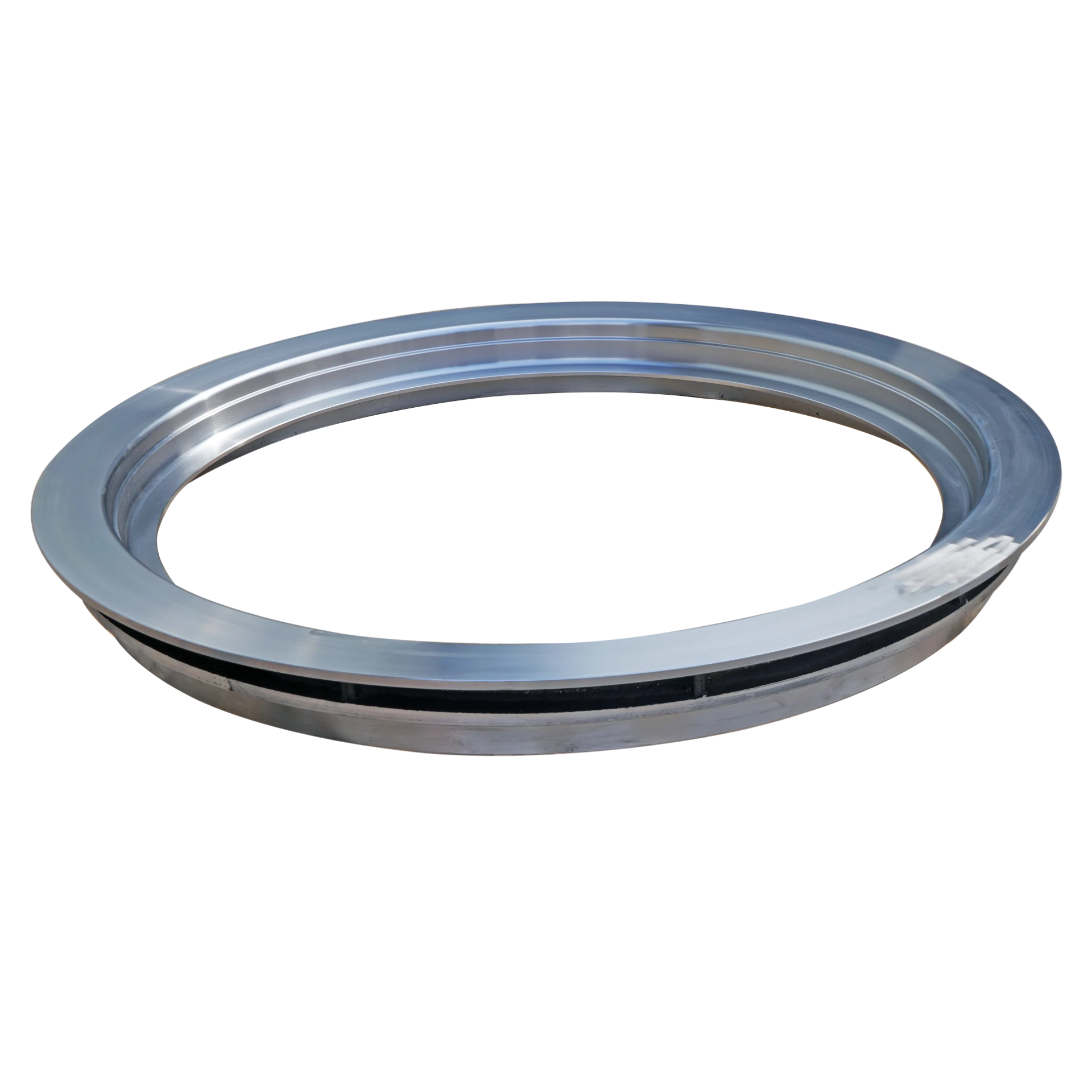

The bell and spigot design itself offers several benefits. The bell refers to the flared end of the pipe, while the spigot is the pointed end that fits snugly into the bell of another pipe. This joint configuration allows for a watertight seal, ensuring that leaks are minimized. The mechanical interlock created by the bell and spigot design also allows for movement in the pipe, accommodating shifts in the ground and reducing the risk of fractures.

Installation of these pipes is relatively straightforward. They can be connected using various methods, including rubber gaskets that enhance flexibility and reduce the likelihood of leaks during ground movement. As a result, construction and installation times are reduced, providing further economic advantages over other types of piping.

Moreover, bell and spigot ductile iron pipes are capable of handling high pressure, making them suitable for both potable water and wastewater applications. Their robust design allows them to withstand the stresses imposed by fluid flow and external forces, making them ideal for urban environments where such demands are common.

In conclusion, the bell and spigot ductile iron pipe system represents a resilient solution for water distribution and sewage systems. The combination of ductile iron's strength, the efficiency of the bell and spigot joint, and the resistance to corrosion makes this type of piping exceptionally well-suited for modern infrastructure demands. As cities and communities continue to evolve, the use of ductile iron pipes will likely remain prevalent, contributing to sustainable and reliable water management systems across the globe.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025