Νοέ . 26, 2024 11:20 Back to list

Top Die Casting Manufacturers and Suppliers for Quality Metal Components

The Importance of Die Casting Suppliers in Modern Manufacturing

In today’s fast-paced manufacturing environment, the role of die casting suppliers cannot be overstated. These suppliers provide essential services and components that are integral to the production processes of various industries, including automotive, aerospace, electronics, and consumer goods. With advancements in technology and increasing demand for high-quality products, selecting the right die casting supplier has become a critical decision for manufacturers.

Understanding Die Casting

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method is favored for its ability to produce intricate shapes with excellent surface finishes and tight tolerances. Common materials used in die casting include aluminum, zinc, magnesium, and copper alloys. The benefits of die casting include reduced material waste, improved mechanical properties, and the ability to produce large quantities of parts efficiently.

The Role of Die Casting Suppliers

Die casting suppliers are specialist organizations that offer a wide range of products and services related to the die casting process. Their roles may include

1. Design and Engineering Expertise Many die casting suppliers provide design services to help manufacturers create parts that optimize the die casting process. This can include advice on part geometry, material selection, and tooling designs.

2. Tooling Fabrication Suppliers often have in-house capabilities to produce custom molds and tooling necessary for die casting. The quality of these tools directly impacts the final product’s quality and production efficiency.

3. Material Supply High-grade alloys are crucial for effective die casting. Suppliers are responsible for ensuring that the raw materials meet strict standards and specifications to guarantee the integrity of the final products.

4. Production and Finishing Services Die casting suppliers typically handle the complete production process, from casting to finishing operations such as machining, surface treatment, and assembly. This integration helps streamline the supply chain and improve overall manufacturing efficiency.

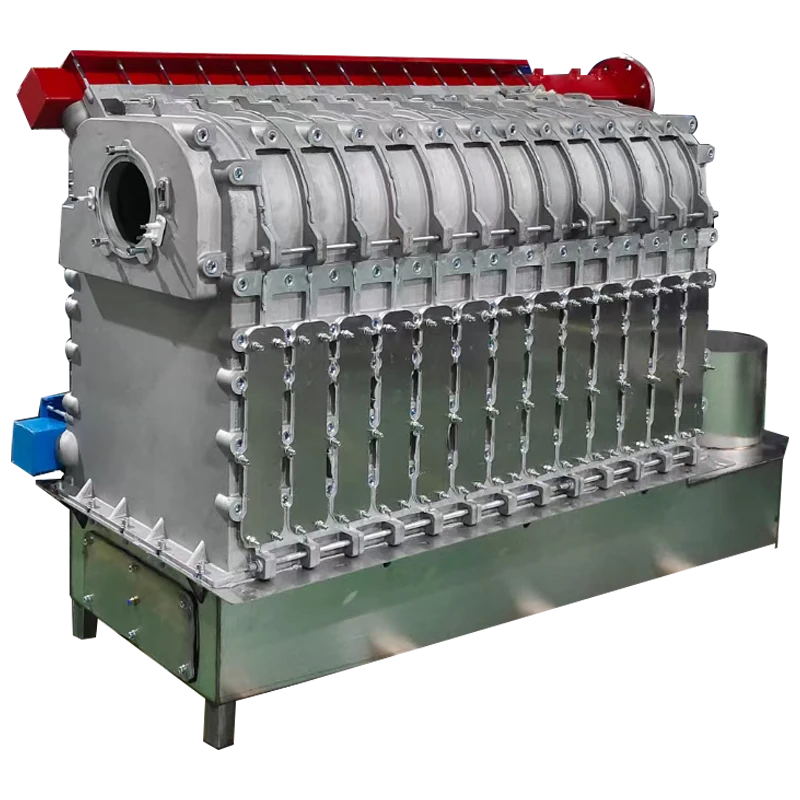

die casting suppliers

5. Quality Assurance A reliable die casting supplier implements rigorous quality control measures to ensure that each part meets the required specifications. This includes inspections, testing, and compliance with industry standards.

Choosing the Right Die Casting Supplier

Selecting a die casting supplier is a significant decision that requires careful consideration. Here are some key factors to evaluate when choosing a supplier

- Experience and Expertise Look for suppliers with a proven track record in your specific industry. An experienced supplier will understand the unique challenges of your products and offer tailored solutions.

- Technological Capabilities Ensure that the supplier uses advanced technology and modern equipment to produce high-quality parts. This includes using sophisticated software for design and simulation, as well as state-of-the-art machinery for the casting process.

- Quality Certifications Check if the supplier holds relevant quality certifications, such as ISO 9001, which indicate adherence to international quality management standards.

- Customer Support Effective communication and support are vital for a successful partnership. Choose a supplier that is responsive and willing to collaborate with you throughout the project.

- Cost Competitiveness While price should not be the sole determining factor, it is essential to compare costs among suppliers to ensure you are getting a good value for the services provided.

Conclusion

In conclusion, die casting suppliers play a crucial role in the success of manufacturing operations across various industries. By understanding the importance of their roles and carefully selecting the right supplier, manufacturers can enhance their production processes, reduce costs, and improve product quality. As the industry continues to evolve, partnerships with reliable die casting suppliers will remain a key factor in maintaining competitiveness and meeting market demands.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025