jan . 20, 2025 00:43 Back to list

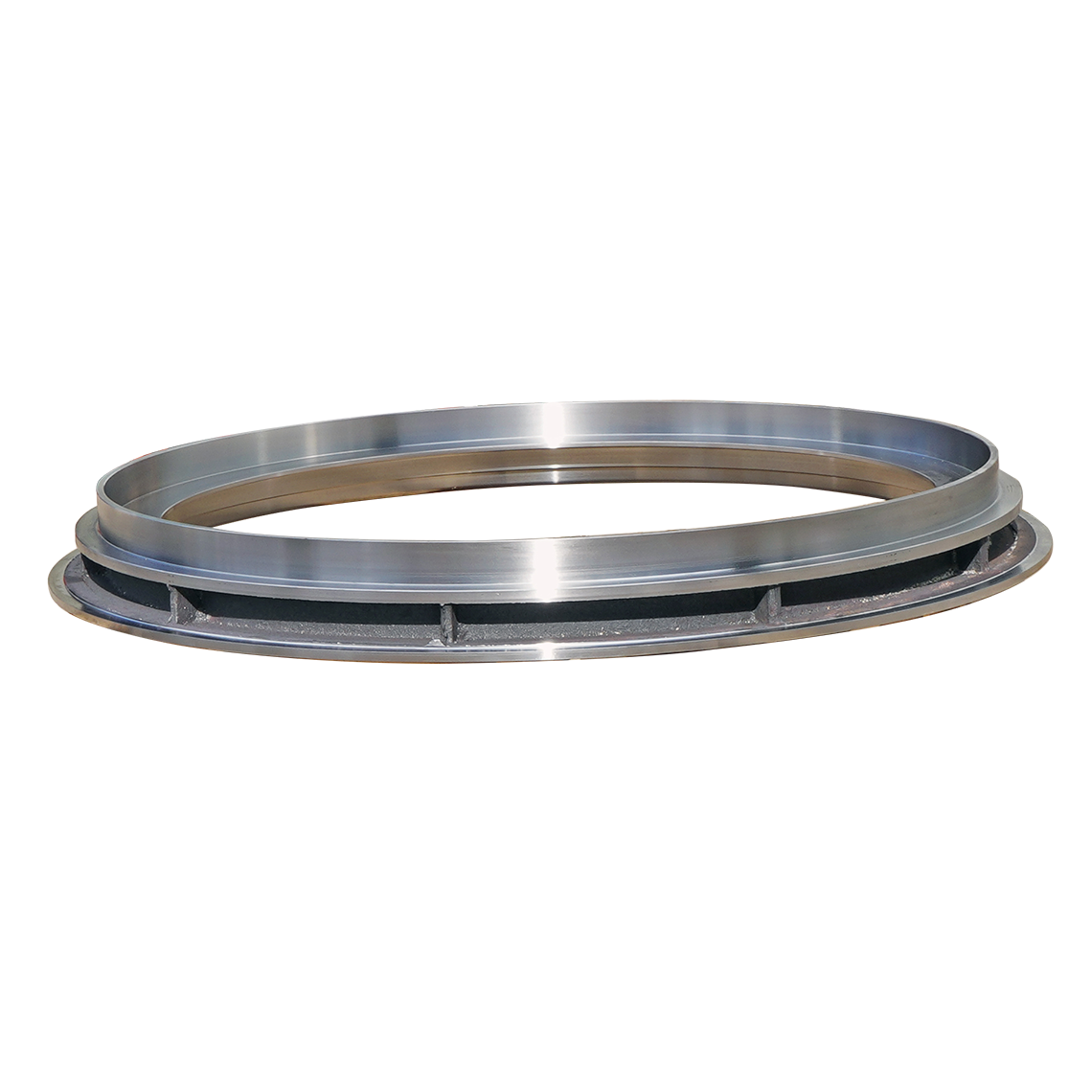

silica sol casting

Silica sol casting, often synonymous with investment casting, has been steadily gaining prominence in the manufacturing world due to its ability to produce intricate and high-quality metal components. With years of experience in the domain, I have witnessed firsthand the transformative potential of silica sol casting in industries ranging from aerospace to medical devices. This technique stands out primarily due to its precision, cost-effectiveness, and compatibility with various metals, making it a go-to choice for manufacturers seeking optimal results.

The versatility of silica sol casting cannot be overstated. It offers manufacturers the flexibility to work with a wide array of metals and alloys including stainless steel, carbon steel, and aluminum, to name a few. This adaptability widens the application spectrum, catering to diverse industry needs. For businesses contemplating the adoption of silica sol casting, partnering with experienced foundries that specialize in this technique is crucial. Such partnerships ensure that not only is the technical expertise applied, but economies of scale are achieved, providing a competitive edge in the market. The ecological benefits of silica sol casting also contribute to its growing demand. Given that environmental sustainability has become increasingly important across industries, the non-toxic nature of silica sol aligns with eco-friendly manufacturing practices. Unlike traditional casting methods that might entail hazardous binders and produce more waste, silica sol casting minimizes environmental impact, which is a significant consideration for companies aspiring to sustainable operations. In conclusion, the utilization of silica sol casting within a production strategy signals a commitment to quality, precision, and reliability. Its ability to produce complex geometries with minimal waste and reduced post-processing efforts offers manufacturers substantial benefits in terms of efficiency and cost. With its versatility in material usage and its alignment with sustainable practices, silica sol casting continues to reinforce its position as a valuable technique in the evolving landscape of manufacturing technologies. As markets grow increasingly competitive, adopting advanced methods like silica sol casting can offer significant strategic advantages and ensure positioning as a leader in quality production.

The versatility of silica sol casting cannot be overstated. It offers manufacturers the flexibility to work with a wide array of metals and alloys including stainless steel, carbon steel, and aluminum, to name a few. This adaptability widens the application spectrum, catering to diverse industry needs. For businesses contemplating the adoption of silica sol casting, partnering with experienced foundries that specialize in this technique is crucial. Such partnerships ensure that not only is the technical expertise applied, but economies of scale are achieved, providing a competitive edge in the market. The ecological benefits of silica sol casting also contribute to its growing demand. Given that environmental sustainability has become increasingly important across industries, the non-toxic nature of silica sol aligns with eco-friendly manufacturing practices. Unlike traditional casting methods that might entail hazardous binders and produce more waste, silica sol casting minimizes environmental impact, which is a significant consideration for companies aspiring to sustainable operations. In conclusion, the utilization of silica sol casting within a production strategy signals a commitment to quality, precision, and reliability. Its ability to produce complex geometries with minimal waste and reduced post-processing efforts offers manufacturers substantial benefits in terms of efficiency and cost. With its versatility in material usage and its alignment with sustainable practices, silica sol casting continues to reinforce its position as a valuable technique in the evolving landscape of manufacturing technologies. As markets grow increasingly competitive, adopting advanced methods like silica sol casting can offer significant strategic advantages and ensure positioning as a leader in quality production.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025