okt . 06, 2024 17:53 Back to list

stamp concrete pipe mold bottom ring factories

Understanding the Importance of Stamp Concrete Pipe Mold Bottom Ring Factories

In the construction industry, the demand for durable and efficient materials is ever-increasing. One such material that has become essential for infrastructure projects is concrete pipes. To produce these pipes effectively, factories utilize various molds, including stamp concrete pipe mold bottom rings. This article delves into the significance of these factories and the technology behind them, shedding light on their role in modern construction.

The Role of Concrete Pipes

Concrete pipes are widely used in a range of applications, including sewage systems, stormwater management, and drainage solutions. Their durability, resistance to corrosion, and ability to withstand severe conditions make them an ideal choice for municipal and industrial needs. However, the efficiency and quality of these pipes greatly depend on the molds used in their production.

What Are Stamp Concrete Pipe Mold Bottom Rings?

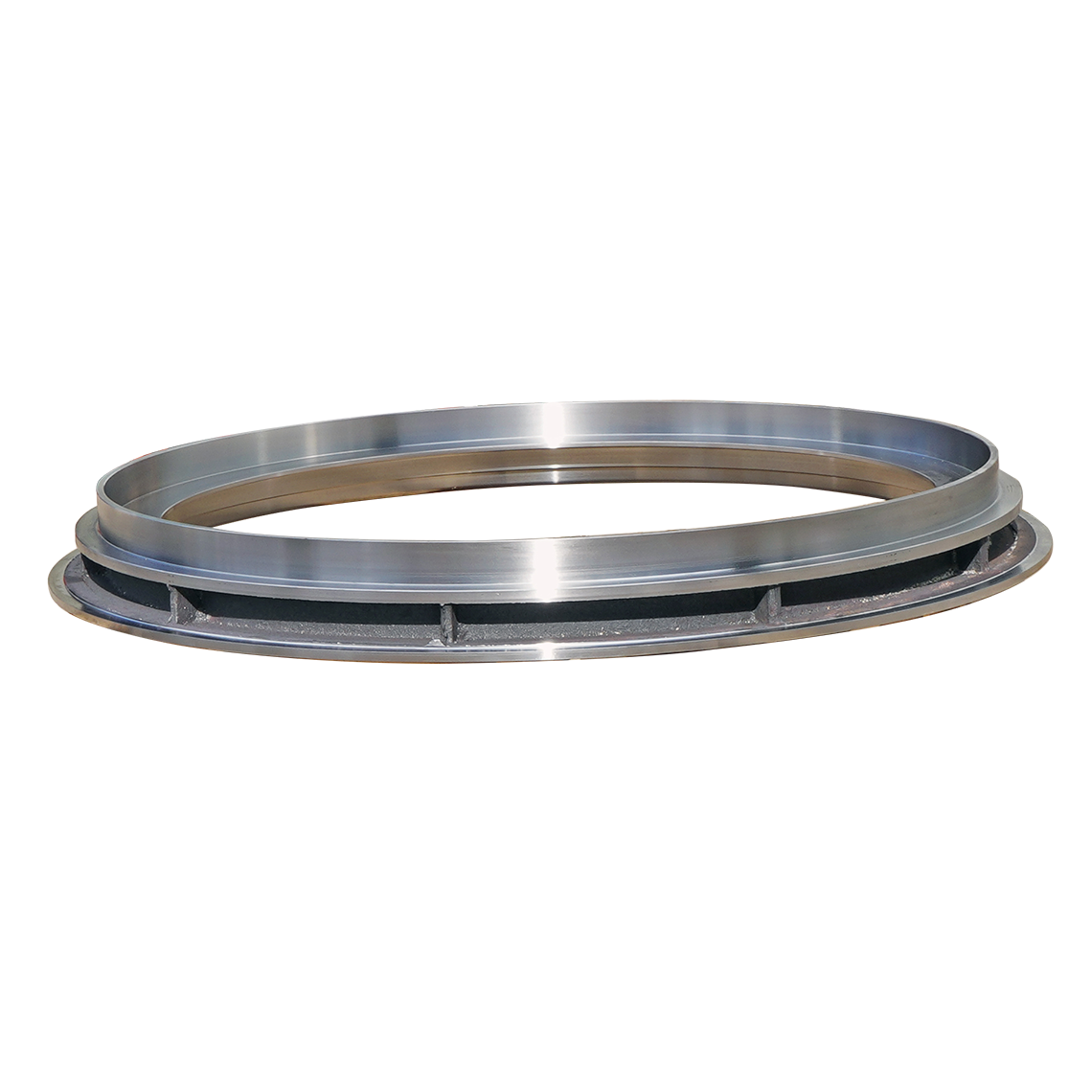

At the heart of concrete pipe manufacturing are molds, which define the shape, size, and texture of the final product. Stamp concrete pipe mold bottom rings are specifically designed components that support the formation of the lower section of the pipe. These molds not only shape the pipes but also enhance their surface finish, contributing to the overall strength and aesthetic appeal of the final product.

The bottom ring molds are typically made from high-quality materials that can withstand the harsh conditions of concrete pour and setting. They are engineered for precision to ensure that the pipes produced are uniform in size and quality, reducing wastage and increasing efficiency in production.

Efficiency in Production

The factories that produce stamp concrete pipe mold bottom rings play a critical role in ensuring that manufacturers can produce high-quality concrete pipes efficiently. By utilizing advanced manufacturing techniques and technology, these factories can create molds that not only fulfill the necessary specifications but also reduce the production time.

stamp concrete pipe mold bottom ring factories

Modern factories often incorporate automation and computer-aided design (CAD) technology to streamline the production process. This advancement allows for rapid prototyping and precise manufacturing, leading to higher consistency in product outputs. The use of durable materials further ensures that the molds have a long lifespan, reducing the need for frequent replacements and maintenance.

Sustainability and Environmental Considerations

In recent years, sustainability has become a crucial consideration in construction and manufacturing. Factories producing stamp concrete pipe mold bottom rings are increasingly focusing on eco-friendly practices. This includes the use of recyclable materials in mold production and implementing processes that minimize waste and energy consumption.

By investing in sustainable practices, these factories contribute to the overall environmental goals of the construction industry. This commitment to sustainability not only helps in reducing the ecological footprint but also appeals to clients who are increasingly inclined towards environmentally friendly options.

Customization and Innovation

One significant advantage of stamp concrete pipe mold bottom ring factories is their ability to offer customized solutions. Different projects may require specific dimensions and features, and factories equipped to handle custom orders can cater to these needs effectively. This flexibility allows manufacturers to provide tailored solutions that meet the unique requirements of each project.

Additionally, innovation in mold design continues to evolve, with the introduction of new technologies such as 3D printing. These advancements enable factories to create complex designs and shapes that were previously difficult to achieve, further pushing the boundaries of what is possible in concrete pipe manufacturing.

Conclusion

Stamp concrete pipe mold bottom ring factories are integral to the construction industry, providing the molds necessary for producing high-quality concrete pipes. Their role in enhancing efficiency, supporting sustainability initiatives, and offering customized solutions underscores their significance in modern manufacturing. As technology continues to advance, these factories will undoubtedly play a crucial part in shaping the future of construction and infrastructure development. Through innovation and a commitment to quality, they contribute not only to the success of individual projects but also to the broader goals of sustainability and efficiency in the industry.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025