Dic . 14, 2024 18:03 Back to list

Casting Steel Pipe Mould Base Ring Supplier for Durable Production Solutions

The Significance of Cast Steel Pipe Mould Bottom Ring Manufacturers

In the world of industrial manufacturing, the production of high-quality pipes is essential for various applications, including construction, plumbing, and energy sectors. One critical component in the pipe manufacturing process is the mould used to shape cast steel pipes, specifically the bottom ring of the mould. Understanding the role and significance of cast steel pipe mould bottom ring manufacturers can provide insight into the broader manufacturing landscape.

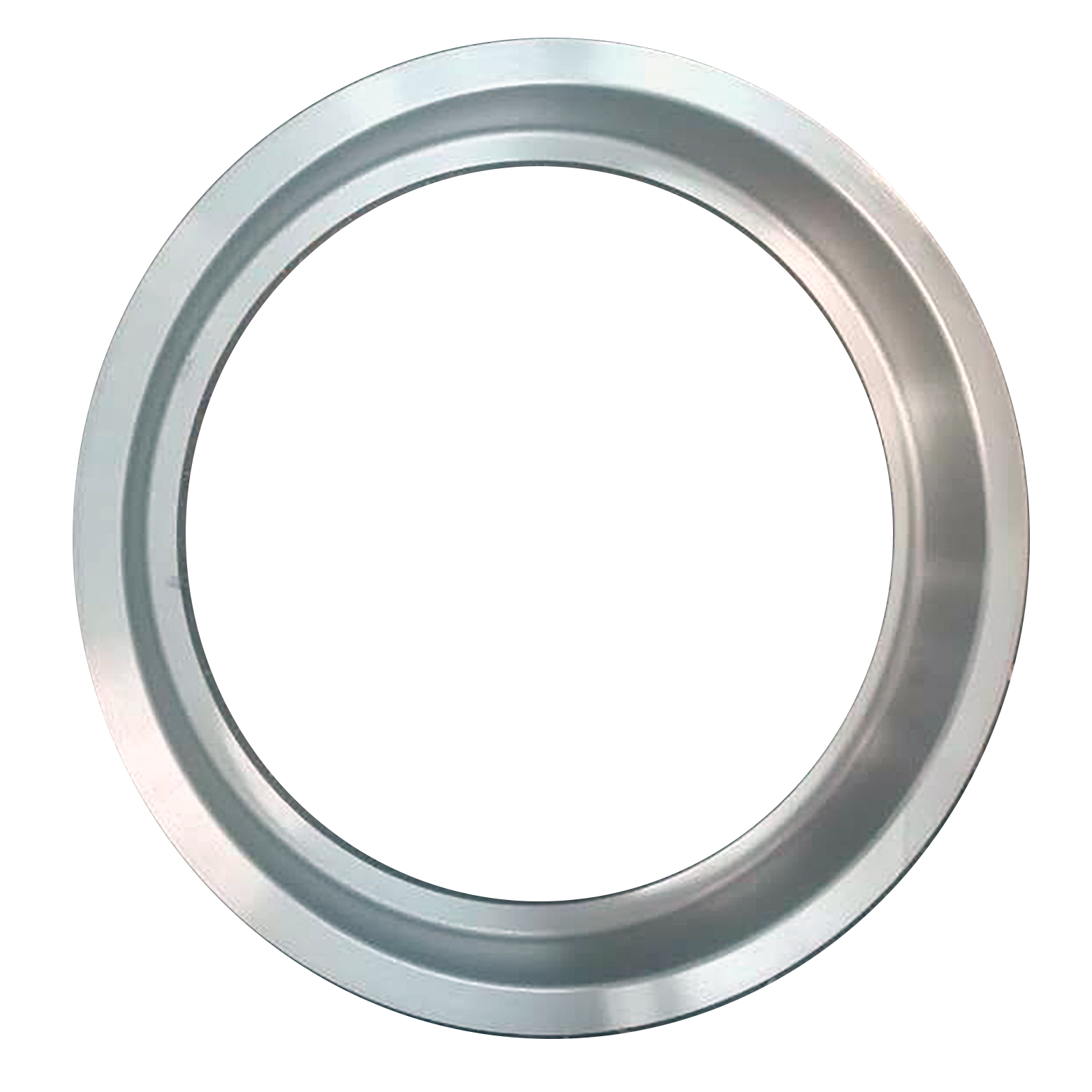

What is a Cast Steel Pipe Mould Bottom Ring?

A cast steel pipe mould bottom ring is a crucial part of the pipe moulding process. It serves as the foundation that shapes the end of each pipe, ensuring uniformity and strength in the final product. These rings are typically manufactured from cast steel due to its excellent mechanical properties, which include high tensile strength, durability, and resistance to deformation under pressure. The design and quality of the bottom ring directly influence the performance of the pipe produced.

Importance of Manufacturers

Manufacturers of cast steel pipe mould bottom rings play an essential role in the pipe production industry

. They are responsible for creating high-quality mould components that meet specific industry standards and customer requirements. The manufacturing process involves intricate designs, precision engineering, and quality control measures to ensure the end product is reliable and efficient.1. Precision Engineering The manufacturing process involves high precision in both design and production. Modern manufacturers utilize advanced technologies such as Computer Numerical Control (CNC) machining and 3D modeling to achieve precise dimensions and shapes. This level of accuracy is crucial, as even minor deviations can lead to significant defects in the final pipes.

cast steel pipe mould bottom ring manufacturer

2. Material Quality The choice of material is pivotal. Cast steel offers several advantages over other materials, including increased strength and resistance to wear and tear. Reliable manufacturers source high-quality steel alloys to fabricate bottom rings that can withstand the rigors of the pipe formation process.

3. Customization Each manufacturing project comes with its unique requirements. Reputable manufacturers offer customization options for their mould bottom rings, allowing clients to specify dimensions, designs, and other features that cater to their specific operational needs. This flexibility enhances the efficiency and performance of pipe production.

4. Testing and Quality Assurance A crucial aspect of manufacturing is quality assurance. Manufacturers conduct rigorous testing on their products to ensure they meet industry standards. This includes material testing for integrity, dimensional accuracy, and surface finish. Such thorough checks help minimize the risks of defects and ensure the longevity and reliability of the moulds.

5. Sustainability With growing concerns about environmental impacts, many manufacturers are incorporating sustainable practices into their production processes. This includes recycling scrap materials, reducing waste, and adhering to eco-friendly production methods. By prioritizing sustainability, manufacturers not only contribute to environmental protection but can also enhance their market competitiveness.

Conclusion

The role of cast steel pipe mould bottom ring manufacturers is vital in the overall pipe manufacturing process. Their expertise in precision engineering, material quality, customization, rigorous testing, and commitment to sustainability sets the foundation for producing high-quality pipes. As industries continue to evolve and demand for reliable infrastructure grows, these manufacturers will remain key players in ensuring that the products they create meet both current standards and future expectations.

Investing in a trustworthy manufacturer can result in enhanced efficiency and performance in pipe production, leading to significant long-term benefits for businesses across various sectors. As the landscape of manufacturing evolves, the importance of high-quality components like cast steel pipe mould bottom rings will only continue to grow.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025