Dic . 17, 2024 03:44 Back to list

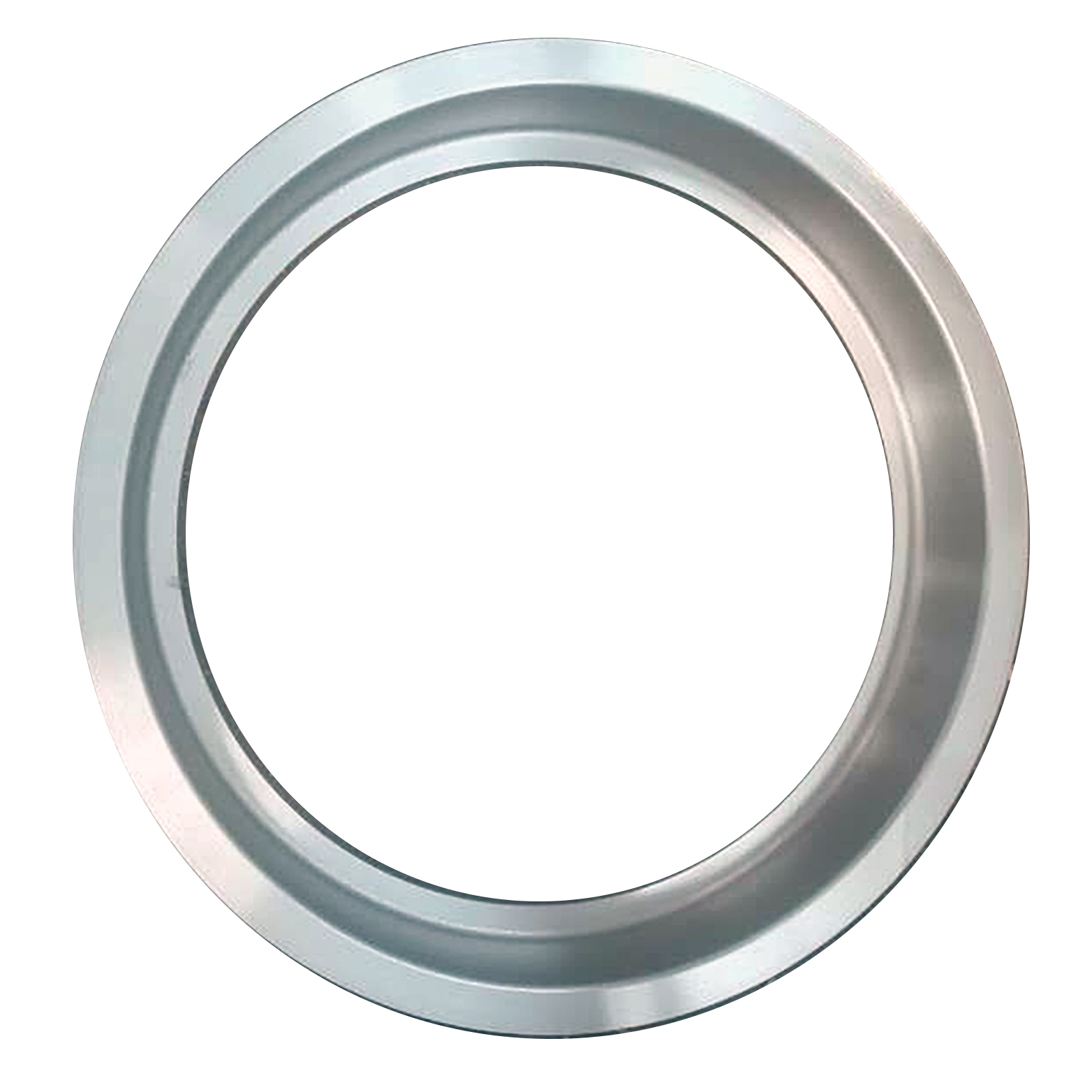

Manufacturer of Dry Cast Reinforced Concrete Pipe Mould Bottom Rings for Enhanced Durability

The Importance of Dry Cast Reinforced Concrete Pipe Mould Bottom Rings A Manufacturer's Perspective

In the construction and civil engineering sectors, the durability and strength of components play a critical role in the success of projects. One such component that often goes unnoticed yet serves a vital function is the dry cast reinforced concrete pipe mould bottom ring. This article will explore the significance of these products, the manufacturing process, and the benefits they offer to various applications.

Understanding Dry Cast Reinforced Concrete

Dry cast concrete refers to a type of concrete mixture that contains very little water, generally around 2-5% moisture. This unique mixture allows for the creation of strong, dense, and durable products, making it ideal for structural components in demanding environments. Reinforced concrete takes this a step further by incorporating steel reinforcement bars or mesh, which significantly boosts its tensile strength.

When it comes to producing pipes, the mould used plays a crucial role in determining the final product's quality. A well-designed mould can ensure uniformity, facilitate efficient production, and enhance the overall durability of the pipes.

The Role of Bottom Rings in Pipe Moulds

Bottom rings serve as the foundation of pipe moulds, providing essential support and stability during the casting process. These rings must withstand considerable weight and pressure as the concrete sets, making quality and precision in their manufacturing pivotal.

Dry cast reinforced concrete pipe mould bottom rings are particularly beneficial because they are designed to endure the harsh physical stresses encountered in the production and transportation of concrete pipes. They help maintain the shape and structure of the moulds, ensuring that the final pipes meet engineering standards.

Manufacturing Process

The manufacturing of dry cast reinforced concrete pipe mould bottom rings involves several critical steps

1. Material Selection High-quality raw materials are essential for producing durable bottom rings. Manufacturers often use a combination of cement, aggregates, and reinforcement materials, which are carefully chosen for their mechanical properties.

2. Mixing The dry cast mixture is prepared in precise proportions, ensuring that it achieves the required strength and consistency. The low water content in the mix allows for lower permeability and enhances the durability of the final product.

dry cast reinfored concrete pipe mould bottom ring manufacturer

3. Moulding The dry cast concrete is then placed into specially designed moulds. The use of vibration and compaction techniques helps to eliminate air pockets, ensuring an even distribution of material.

4. Curing Although dry cast concrete requires less curing time, it is still necessary to allow the material to set and gain strength. Curing can be done using various methods, depending on the specific requirements of the product.

5. Quality Control After the bottom rings are produced, they undergo rigorous quality control checks to ensure they meet industry standards and specifications. This step is essential to guarantee that the final product is robust and reliable.

Benefits of Dry Cast Reinforced Concrete Pipe Mould Bottom Rings

The utilization of dry cast reinforced concrete pipe mould bottom rings offers numerous advantages

- Enhanced Durability The combination of dry cast technology and reinforcement features leads to products that can withstand extreme weather conditions and loads.

- Cost-Effectiveness While the initial investment may be higher due to the quality of materials and manufacturing processes, the longevity of the pipes produced can lead to significant long-term savings.

- Versatility These rings can be used in various applications, from stormwater drainage systems to sewage disposal, showcasing their adaptability to different environmental conditions.

- Environmental Considerations Utilizing reinforced concrete helps in reducing the carbon footprint associated with construction projects, as these materials can often be sourced sustainably.

Conclusion

As a manufacturer of dry cast reinforced concrete pipe mould bottom rings, the focus on quality, durability, and innovation is paramount. By understanding the critical role these bottom rings play in the pipe manufacturing process, one can appreciate their contribution to the overall infrastructure development. With advancements in technology and materials, the future of dry cast reinforced concrete components looks promising, paving the way for robust, long-lasting solutions in the construction industry.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025