dets. . 14, 2024 13:54 Back to list

Ductile Iron Casting Services in the USA for High-Quality Foundry Solutions

Ductile Iron Foundry in the USA A Comprehensive Overview

Ductile iron, also known as spheroidal graphite iron, has emerged as a transformative material in various industries due to its unique combination of strength, elasticity, and castability. In the United States, the ductile iron foundry industry plays a pivotal role in manufacturing components for a wide range of sectors, including automotive, construction, and plumbing. This article delves into the significance of ductile iron foundries in the USA, exploring their processes, applications, and future prospects.

The Process of Ductile Iron Casting

The production of ductile iron begins with the careful selection of raw materials, often including iron scrap, pig iron, and residual metals. The primary process involves melting these materials in an electric arc furnace or induction furnace. During melting, the addition of alloying elements, such as magnesium, is crucial as it influences the formation of graphite in the iron. The introduction of magnesium creates a transformation in the microstructure of the cast iron, resulting in the formation of nodular graphite, which is responsible for the material's enhanced ductility and strength.

Once the iron is molten, it is poured into molds to cool and solidify. The casting process can be tailored to produce various shapes and sizes, making ductile iron an ideal choice for complex components. After casting, the parts undergo several finishing processes, such as machining, surface treatment, and heat treatment, to meet stringent specifications and tolerances required by clients.

Applications of Ductile Iron

Ductile iron is widely appreciated for its mechanical properties, making it suitable for various applications. In the automotive industry, ductile iron is commonly used for manufacturing engine blocks, crankshafts, and suspension components. Its high strength-to-weight ratio contributes to improved fuel efficiency and performance.

The construction industry also benefits from ductile iron components, particularly in the form of pipes and fittings for water and sewage systems. Ductile iron pipes are known for their durability, corrosion resistance, and ability to withstand high pressure, making them a reliable choice for infrastructure projects.

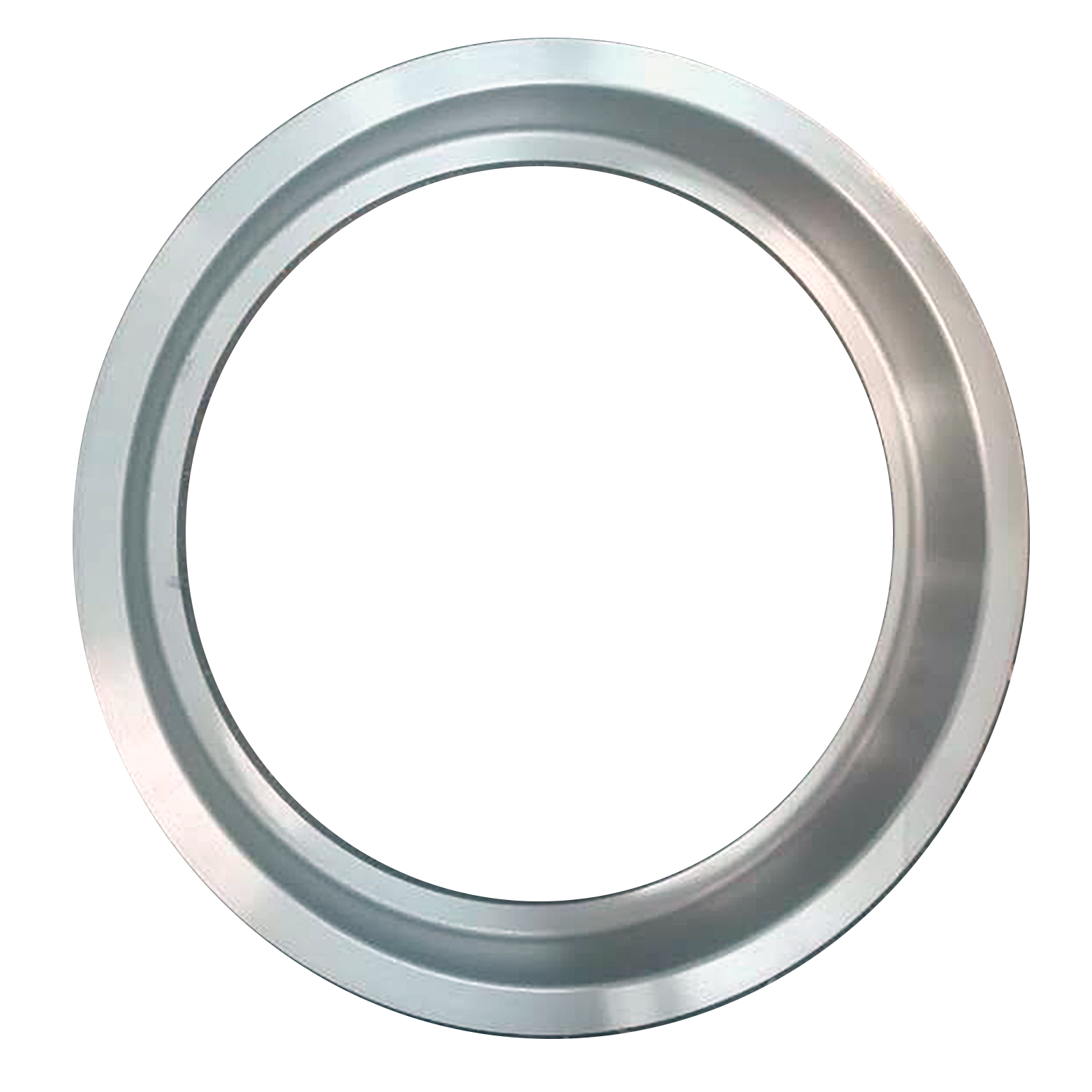

ductile iron foundry usa

Moreover, ductile iron finds applications in the production of agricultural equipment, hand tools, and machinery parts. Its versatility ensures that manufacturers can produce a myriad of products tailored to the specific demands of different industries, thus reinforcing ductile iron’s position as a critical material in modern manufacturing.

Challenges and Future Prospects

Despite its many advantages, the ductile iron foundry industry faces several challenges. The fluctuating prices of raw materials, especially scrap iron and alloying elements, can affect production costs and profitability. Additionally, foundries must navigate the complexities of environmental regulations aimed at reducing emissions and waste, which can require significant investments in cleaner technologies and processes.

To meet these challenges, many foundries are embracing innovation, investing in state-of-the-art equipment and processes that enhance efficiency and sustainability. Furthermore, advancements in casting technology, such as 3D printing and improved molding techniques, are paving the way for more precise and cost-effective production methods.

The future of the ductile iron foundry industry in the USA looks promising. As the demand for lightweight and durable materials continues to rise in various sectors, ductile iron is poised to meet these needs. The ongoing development of eco-friendly production practices and the potential integration of smart manufacturing technologies may further strengthen the industry's position in the global market.

Conclusion

In conclusion, ductile iron foundries in the USA are integral to the manufacturing landscape, providing essential components for numerous industries. With their unique manufacturing processes and wide-ranging applications, these foundries contribute significantly to the strength and resilience of American manufacturing. By addressing challenges and embracing innovation, the ductile iron foundry industry is well-positioned for future growth, continuing to play a vital role in the country's economic development. As industries evolve and new technologies emerge, ductile iron remains a cornerstone material, ensuring the continued success and sustainability of American foundries.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025