Abe . 07, 2024 08:14 Back to list

Purchase Dry Cast Reinforced Concrete Pipe Mould Pallet for Efficient Manufacturing Solutions

Understanding the Importance of Dry Cast Reinforced Concrete Pipe Mould Pallets in Modern Construction

In the realm of construction and civil engineering, the use of concrete is paramount due to its durability, strength, and versatility. Among the myriad of concrete products, dry cast reinforced concrete pipes stand out as essential components in various infrastructural projects, including water management systems and drainage solutions. To efficiently produce these pipes, the use of high-quality moulds and pallets is indispensable. This article delves into the significance of dry cast reinforced concrete pipe mould pallets, their features, and the advantages they offer to manufacturers.

The Basics of Dry Cast Reinforced Concrete Pipes

Before delving into the mould pallets, it is essential to understand what dry cast reinforced concrete pipes are. Unlike traditional wet-cast concrete products, dry cast methods use a low water-to-cement ratio, resulting in a denser and more durable final product. Reinforcement, typically through the inclusion of steel bars or mesh, enhances the structural integrity of the pipes, making them ideal for applications that require strength, such as stormwater drainage and sewage systems.

These pipes are often produced in a factory setting, allowing for greater control over the manufacturing process and resulting in higher quality. However, the key to producing these high-quality pipes lies significantly in the moulds and pallets used during production.

The Role of Moulds and Pallets

Concrete pipe moulds and pallets are critical in determining the shape, size, and finish of the reinforced concrete pipes. Moulds are designed to offer precision in the formation of the pipes, while pallets serve as a stable base to support the moulds during the curing process. The collaboration between moulds and pallets ensures that the pipes can be demoulded efficiently without compromising the quality or integrity of the product.

Dry cast moulds are built to withstand the rigors of the manufacturing process. They are typically made from high-quality materials such as steel or composite materials, which provide strength and durability. The design of these moulds affects the pipe's internal and external surface finishes, which can influence the performance of the pipes in practical applications.

Advantages of Using Dry Cast Reinforced Concrete Pipe Mould Pallets

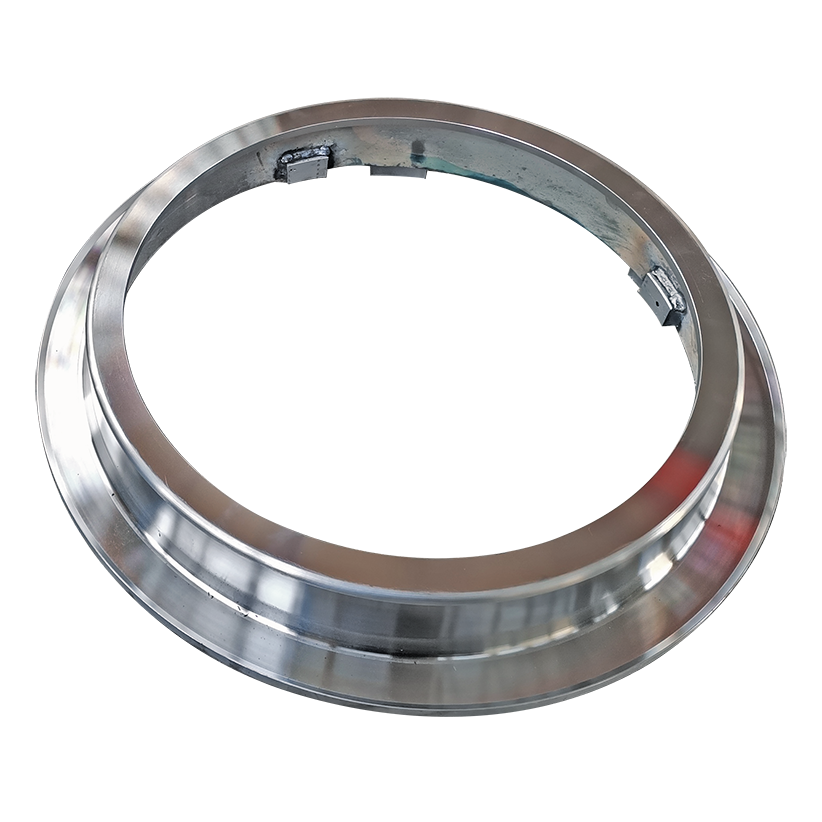

buy dry cast reinfored concrete pipe mould pallet

1. Durability and Longevity One of the most significant benefits of using high-quality moulds and pallets is their durability. Properly designed and maintained moulds can produce thousands of pipes over their lifespan, making them a worthwhile investment for manufacturers.

2. Precision Manufacturing The use of advanced technology and techniques in designing moulds ensures that each concrete pipe produced meets exact specifications. This precision is crucial for applications where fit and function are critical, such as in underground drainage systems.

3. Enhanced Production Efficiency Efficient moulds and pallets allow for quicker turnaround times in the production process. The ability to produce more pipes in a shorter time frame can significantly reduce operational costs and increase profitability for manufacturers.

4. Improved Quality Control With the right moulds, manufacturers can achieve consistent quality across all products. This uniformity is essential for meeting industry standards and ensuring the reliability of the pipes in the field.

5. Customization Options Moulds can be designed and modified to create pipes of various sizes and specifications, catering to specific project requirements. This adaptability is particularly advantageous in a diverse construction landscape where custom solutions are often needed.

6. Eco-Friendly Production The manufacturing process for dry cast reinforced concrete is more sustainable than traditional methods, requiring less water and producing less waste. Moreover, using durable moulds extends their lifespan, contributing to reduced resource consumption over time.

Conclusion

In conclusion, the use of dry cast reinforced concrete pipe mould pallets plays a fundamental role in modern construction. They not only enable the efficient and precise production of high-quality concrete pipes but also contribute to the sustainability and profitability of manufacturing processes. As the demand for reliable infrastructure continues to grow, investing in excellent mould technology will undoubtedly equip manufacturers to meet future challenges head-on, ensuring that they remain competitive in an ever-evolving industry landscape. Emphasizing the importance of these components is critical for any business looking to thrive in the concrete production sector.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025