Abe . 31, 2024 11:32 Back to list

Exploring the Properties and Applications of Flake Cast Iron in Modern Engineering

The Significance of Flake Cast Iron in Modern Manufacturing

Flake cast iron, known for its distinctive graphite structure resembling flakes, has established itself as a significant material in various manufacturing processes. This unique form of cast iron offers specific mechanical properties that make it incredibly versatile for a range of applications. In this article, we will delve into the characteristics, production methodology, benefits, and applications of flake cast iron, shedding light on its crucial role in modern industry.

Characteristics of Flake Cast Iron

Flake cast iron is primarily composed of carbon, silicon, and iron, with the addition of various alloying elements influencing its properties. The defining feature of flake cast iron is its microstructure, which consists of graphite flakes dispersed throughout a matrix of iron. This structure provides several benefits, including enhanced machinability, excellent wear resistance, and good thermal conductivity. The presence of graphite not only enhances the material’s ability to withstand high temperatures but also contributes to its damping capabilities, making it effective in reducing vibrations and noise in machinery.

Production Methodology

The production of flake cast iron involves several key processes. First, raw materials—primarily pig iron, scrap iron, and alloying elements—are melted in a cupola or electric furnace. The molten metal is then poured into molds where it cools and solidifies. During this cooling process, the carbon content in the iron segregates and forms graphite flakes, giving the material its characteristic structure.

Controlling the cooling rate and the chemical composition is crucial in achieving the desired microstructure. Too rapid cooling can lead to unwanted formations like cementite, which can compromise the mechanical properties of the cast iron. Hence, foundries often employ specific techniques and molds designed to optimize cooling rates and enhance the formation of graphite flakes.

Benefits of Flake Cast Iron

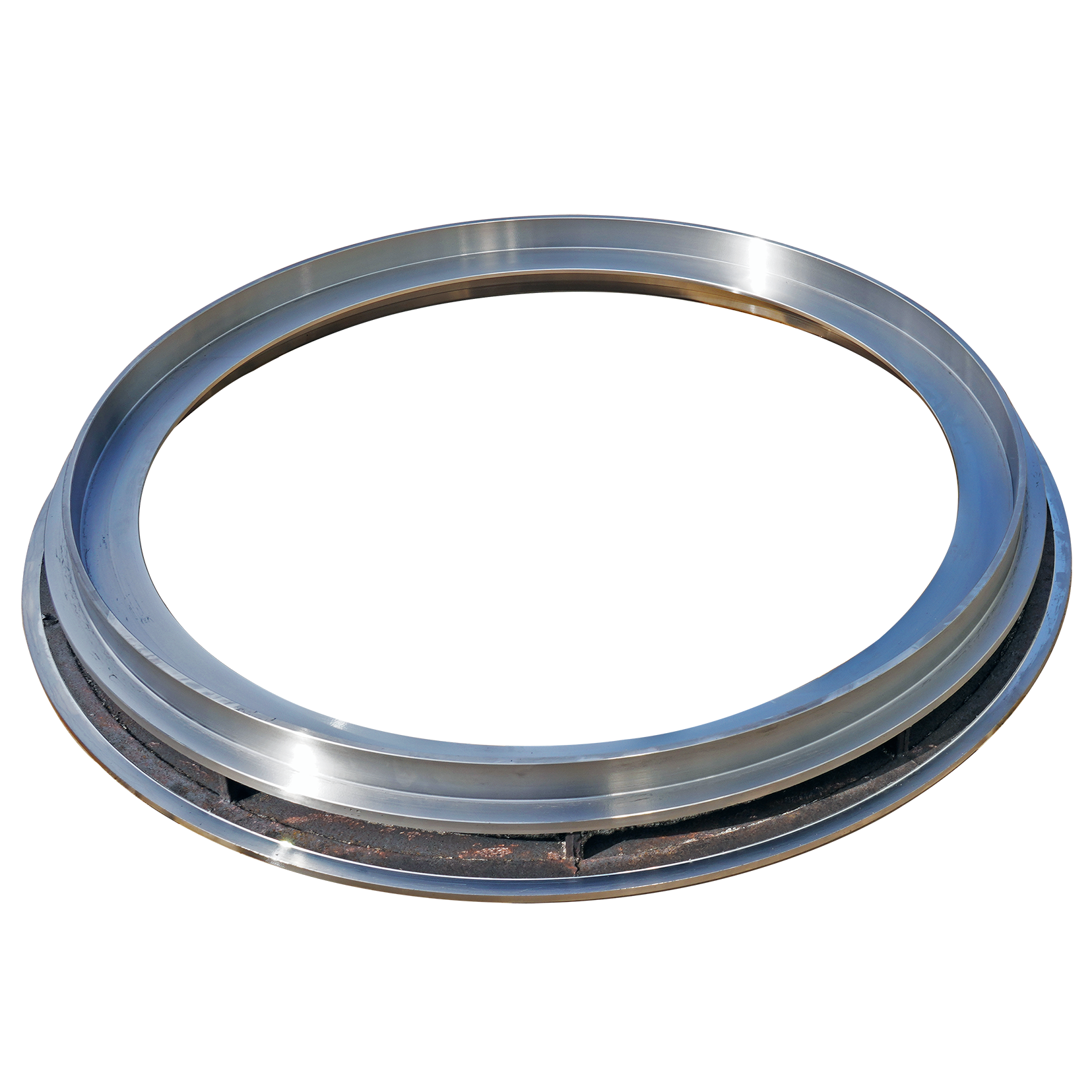

flake cast iron

Flake cast iron offers a multitude of advantages that have made it a preferred choice in various industries. One of the primary benefits is its excellent castability. This means that it can be easily molded into complex shapes while maintaining dimensional accuracy. Additionally, the material has a high strength-to-weight ratio, allowing for the creation of lightweight yet strong components.

Another significant advantage is its resistance to wear and deformation under high loads, making it suitable for applications in machinery and automotive components. The graphite structure also aids in reducing friction, which is crucial in parts that undergo constant movement, such as engine blocks and cylinders. Furthermore, flake cast iron exhibits good thermal conductivity, which is essential in applications where heat dissipation is necessary.

Applications of Flake Cast Iron

The versatility of flake cast iron has led to its widespread use across various sectors. In the automotive industry, it is commonly found in engine blocks, crankshafts, and brake components. These applications benefit from the material's durability, wear resistance, and ability to dissipate heat efficiently.

In the manufacturing sector, flake cast iron is utilized in machine tool construction and various parts that require precision engineering. Its excellent machinability allows for intricate designs and components that meet stringent tolerances. Moreover, flake cast iron is often used in construction and infrastructure, including pipes and manhole covers, due to its strength and resistance to weathering.

Conclusion

In summary, flake cast iron stands as a pivotal material in modern manufacturing, offering a combination of mechanical strength, thermal properties, and durability. Its unique structure provides a variety of benefits that meet the demands of diverse industries, from automotive to construction. As technology and engineering evolve, flake cast iron is likely to continue playing a vital role in developing innovative solutions for complex manufacturing challenges. Understanding its properties, production methods, and applications is essential for engineers and manufacturers who seek to harness the advantages of this remarkable material.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025