touko . 07, 2025 16:06 Back to list

China Grey Iron, Stainless Steel & Brass Casting Parts Custom Machining

- Overview of Casting Parts Manufacturing

- Technical Advantages Across Materials & Methods

- Global Supplier Comparison: Metrics & Pricing

- Custom Solutions for Industrial Requirements

- Material-Specific Use Cases & Performance Data

- Integrated Casting-Machining Workflows

- Strategic Sourcing of Casting Machinery Parts

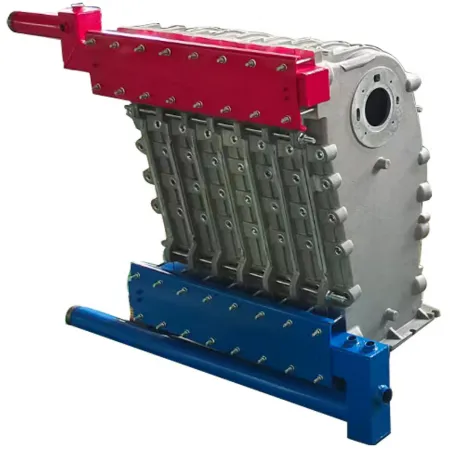

(casting parts)

Global Manufacturing Hub for Precision Casting Parts

China's foundries produce 65% of global grey iron castings, with dimensional accuracy reaching CT8-10 grades. Specialized facilities combine sand casting for large components (up to 80 tons) with investment casting for complex geometries (±0.1mm tolerance). The stainless steel casting sector grows at 7.2% CAGR, driven by chemical and food processing demands.

Technical Advantages Across Materials & Methods

| Process | Surface Finish (Ra) | Cost Index | Lead Time |

|---|---|---|---|

| Sand Casting | 12.5-25μm | 1.0x | 4-6 weeks |

| Investment Casting | 3.2-6.3μm | 2.8x | 8-10 weeks |

| Die Casting | 1.6-3.2μm | 3.5x | 10-12 weeks |

Global Supplier Comparison: Metrics & Pricing

Chinese foundries offer 25-40% cost advantage over European counterparts for brass and copper alloys, maintaining comparable quality (ISO 9001:2015 compliance rate: 92% vs 96%). Domestic sand casting shops achieve 15-day faster turnaround through automated molding lines, while maintaining ≤1.5% defect rates in high-pressure valve bodies.

Custom Solutions for Industrial Requirements

- Stainless steel (CF8M/CF3M) investment castings for corrosive environments

- Grey iron (GG25) sand cast housings with integrated mounting surfaces

- Brass (CZ121) die cast fittings with NPT thread machining

Material-Specific Use Cases & Performance Data

Automotive brake drums in GGG50 ductile iron withstand 800°C thermal shocks during testing. Copper alloy C83600 investment cast pump impellers demonstrate 94% conductivity retention after 2,000hr salt spray exposure. Stainless steel CF8M valve bodies achieve 10,000 PSI pressure ratings in oilfield applications.

Integrated Casting-Machining Workflows

Combined casting and CNC machining reduces total production time by 30% for hydraulic components. Post-casting operations include:

- ±0.02mm boring tolerance on valve bodies

- 63μin surface finish on sealing faces

- Positional accuracy within 0.1mm/300mm

Strategic Sourcing of Casting Machinery Parts

Leading Chinese manufacturers supply replacement die casting components with 12-month performance warranties. Inventory programs for common stainless steel investment casting parts

(1" to 24" sizes) ensure 72-hour shipment availability. Technical support includes GD&T analysis and FEA simulation for critical machinery components.

(casting parts)

FAQS on casting parts

Q: What materials are commonly used for casting parts in China?

A: China widely uses grey iron, stainless steel, brass, and copper for casting parts. These materials are chosen based on strength, corrosion resistance, and application needs. Sand, investment, and die casting methods are applied depending on the material and design complexity.

Q: What are the advantages of investment casting compared to die casting?

A: Investment casting offers high precision and intricate details, ideal for complex stainless steel or brass parts. Die casting is faster and cost-effective for high-volume production. The choice depends on part complexity, material, and budget.

Q: How can I ensure quality when buying investment casting parts?

A: Verify supplier certifications (e.g., ISO) and request material test reports for stainless steel or copper parts. Inspect sample parts for surface finish and dimensional accuracy. Ensure they offer machining services for post-casting requirements.

Q: What post-processing is required for sand-cast brass components?

A: Sand-cast brass parts often need machining to achieve tight tolerances. Surface treatments like polishing or plating may be applied for corrosion resistance. Deburring and inspection ensure compliance with specifications.

Q: Can Chinese suppliers provide both casting and machining services?

A: Yes, many Chinese foundries offer integrated services like die casting with CNC machining for stainless steel or grey iron parts. This reduces lead times and ensures consistency. Confirm their capabilities and quality control processes upfront.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025