tammi . 14, 2025 11:23 Back to list

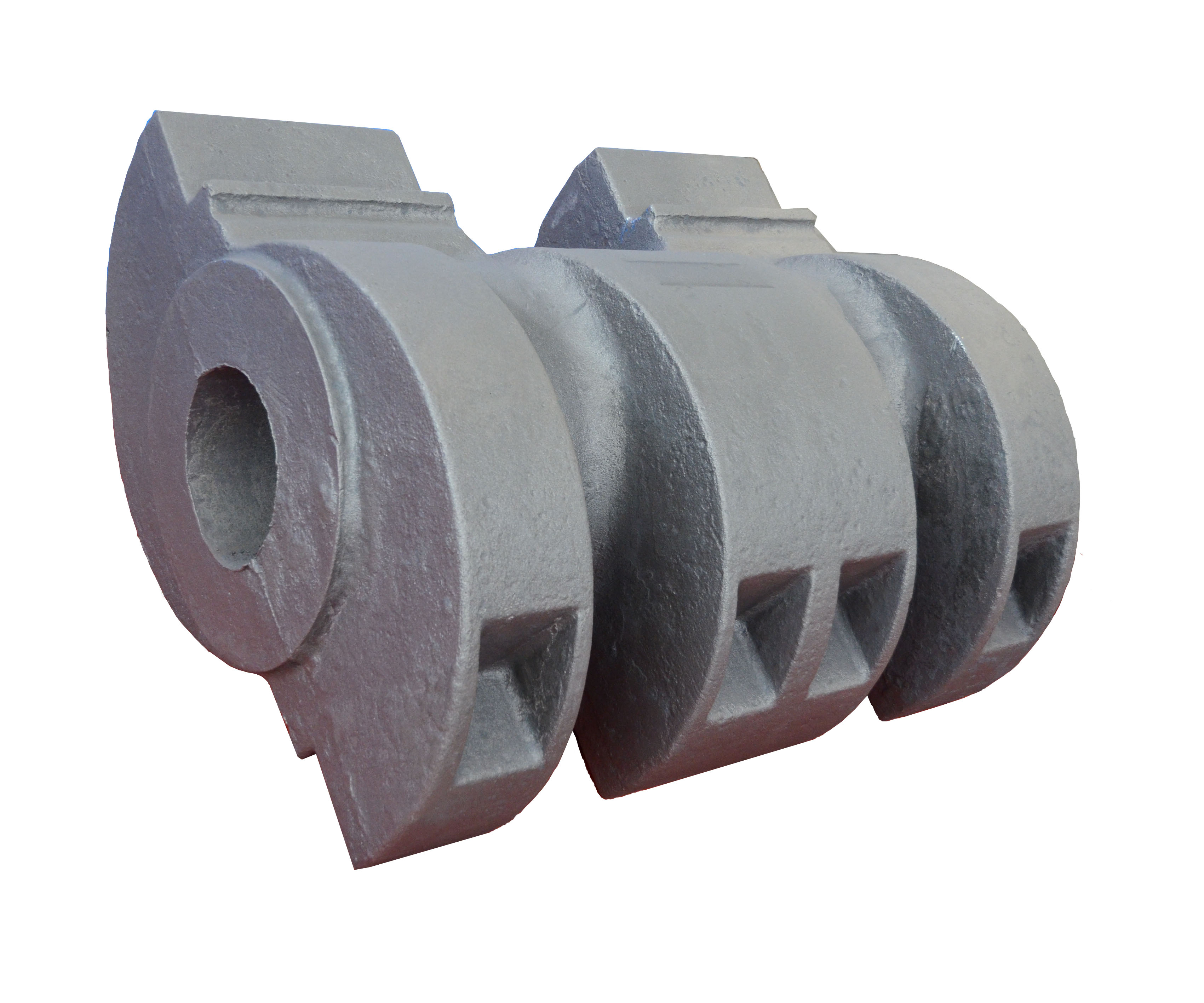

cast silicon aluminum heat exchanger for commercial hot water boiler

When considering the efficiency and durability of commercial hot water boilers, the cast silicon aluminum heat exchanger stands out as a technological advancement that significantly enhances performance. This article delves into the unique advantages and technical aspects of this material, providing a comprehensive understanding for industry professionals seeking to optimize their hot water systems.

In terms of ecological impact, the adoption of silicon aluminum heat exchangers also supports sustainable business practices. The efficiency gains achieved help reduce the carbon footprint of commercial hot water systems, aligning corporate operations with global environmental standards and improving their overall sustainability profile. Trust in the application of cast silicon aluminum heat exchangers is further reinforced by industry endorsements and certifications. Recognized regulatory bodies have validated the performance claims of this material, offering assurance to business owners and facility managers about the long-term viability and return on investment. The decision to integrate silicon aluminum heat exchangers into commercial hot water systems is a testament to foresight and commitment to state-of-the-art technology. By choosing this innovative solution, businesses not only reap the immediate benefits of increased efficiency and cost reduction but also position themselves as leaders in adopting robust, sustainable technologies. In essence, the cast silicon aluminum heat exchanger is not just a component but a pivotal enhancement driving the future of commercial boiler systems. Its capacity to withstand the rigors of demanding commercial environments while ensuring peak performance makes it an invaluable asset in the pursuit of excellence in heating systems.

In terms of ecological impact, the adoption of silicon aluminum heat exchangers also supports sustainable business practices. The efficiency gains achieved help reduce the carbon footprint of commercial hot water systems, aligning corporate operations with global environmental standards and improving their overall sustainability profile. Trust in the application of cast silicon aluminum heat exchangers is further reinforced by industry endorsements and certifications. Recognized regulatory bodies have validated the performance claims of this material, offering assurance to business owners and facility managers about the long-term viability and return on investment. The decision to integrate silicon aluminum heat exchangers into commercial hot water systems is a testament to foresight and commitment to state-of-the-art technology. By choosing this innovative solution, businesses not only reap the immediate benefits of increased efficiency and cost reduction but also position themselves as leaders in adopting robust, sustainable technologies. In essence, the cast silicon aluminum heat exchanger is not just a component but a pivotal enhancement driving the future of commercial boiler systems. Its capacity to withstand the rigors of demanding commercial environments while ensuring peak performance makes it an invaluable asset in the pursuit of excellence in heating systems.

Share

Latest news

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025