joulu . 12, 2024 11:55 Back to list

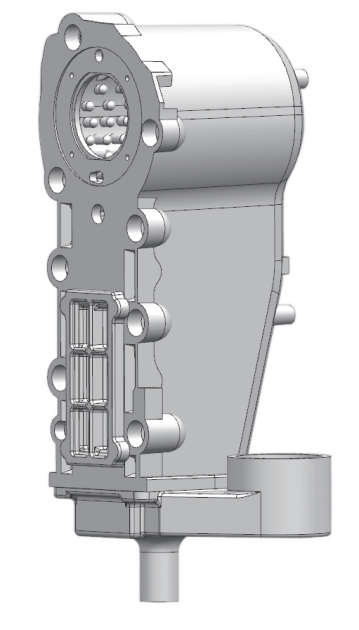

odm die casting

Understanding ODM Die Casting A Comprehensive Overview

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method is widely used in various industries for producing a vast range of metal parts with exceptional precision and surface finish. When we delve into the realm of ODM (Original Design Manufacturer) die casting, we uncover a unique intersection of design, engineering, and production that can significantly impact product development in various sectors.

What is ODM Die Casting?

ODM die casting refers to a manufacturing service where a supplier designs and produces components based on the client's specifications. Unlike traditional manufacturing, where a client might provide the specifics of an existing design, ODM services offer a more comprehensive approach by creating an entirely new design tailored to meet the client's needs. This is particularly beneficial for companies looking to innovate or create unique products without an in-house design team.

In the die casting context, ODM providers leverage extensive experience and expertise in metalworking. They can not only refine existing designs but also generate new ideas that enhance functionality, reduce material costs, or improve product longevity. This collaborative process ensures that the final product is optimized for both performance and manufacturability.

The Process of ODM Die Casting

The ODM die casting process begins with initial brainstorming sessions, where the client outlines their vision and requirements. This stage may involve discussions about materials, potential applications, and any specific challenges the product might face in its operational environment. Once the requirements are established, the ODM supplier typically develops prototypes to refine the design further.

Once the design is finalized, the actual die casting process begins

. This involves several key steps1. Mold Creation A custom mold is created based on the approved design. This mold is often made of high-grade steel to withstand the high temperatures and pressures involved in the casting process.

2. Melting Metal The selected metal, which can vary from aluminum to magnesium or zinc, is melted in a furnace to reach a liquid state.

odm die casting

3. Injection The molten metal is injected into the mold cavity at high pressure. This ensures that the metal fills all the intricate details of the mold, resulting in a high-precision component.

4. Cooling After the metal has cooled and solidified, the mold is opened, and the casting is removed.

5. Finishing The final component may undergo various finishing processes, such as machining, polishing, or surface treatments, to meet the specified tolerances and aesthetic requirements.

Benefits of ODM Die Casting

The advantages of utilizing ODM die casting are numerous

- Customization Clients have the freedom to create bespoke designs that specifically cater to their market demands and operational needs. - Cost-Effectiveness By outsourcing the design and manufacturing process, companies can reduce overhead costs and focus their resources on core business areas.

- Speed to Market With the help of experienced ODM suppliers, companies can shorten the development cycle, allowing them to bring products to market faster.

- Quality Assurance Established ODM die casting manufacturers often have rigorous quality control processes in place, ensuring that the products meet strict industry standards.

Conclusion

ODM die casting represents a valuable opportunity for businesses seeking to innovate and expand their product lines. By collaborating with experts who understand the nuances of design and manufacturing, companies can harness the benefits of advanced die casting techniques while ensuring that their products are tailored to the specific needs of their target markets. As industries continue to evolve, the role of ODM die casting in facilitating product development and enhancing competitiveness will undoubtedly remain significant.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025