Nov . 28, 2024 04:16 Back to list

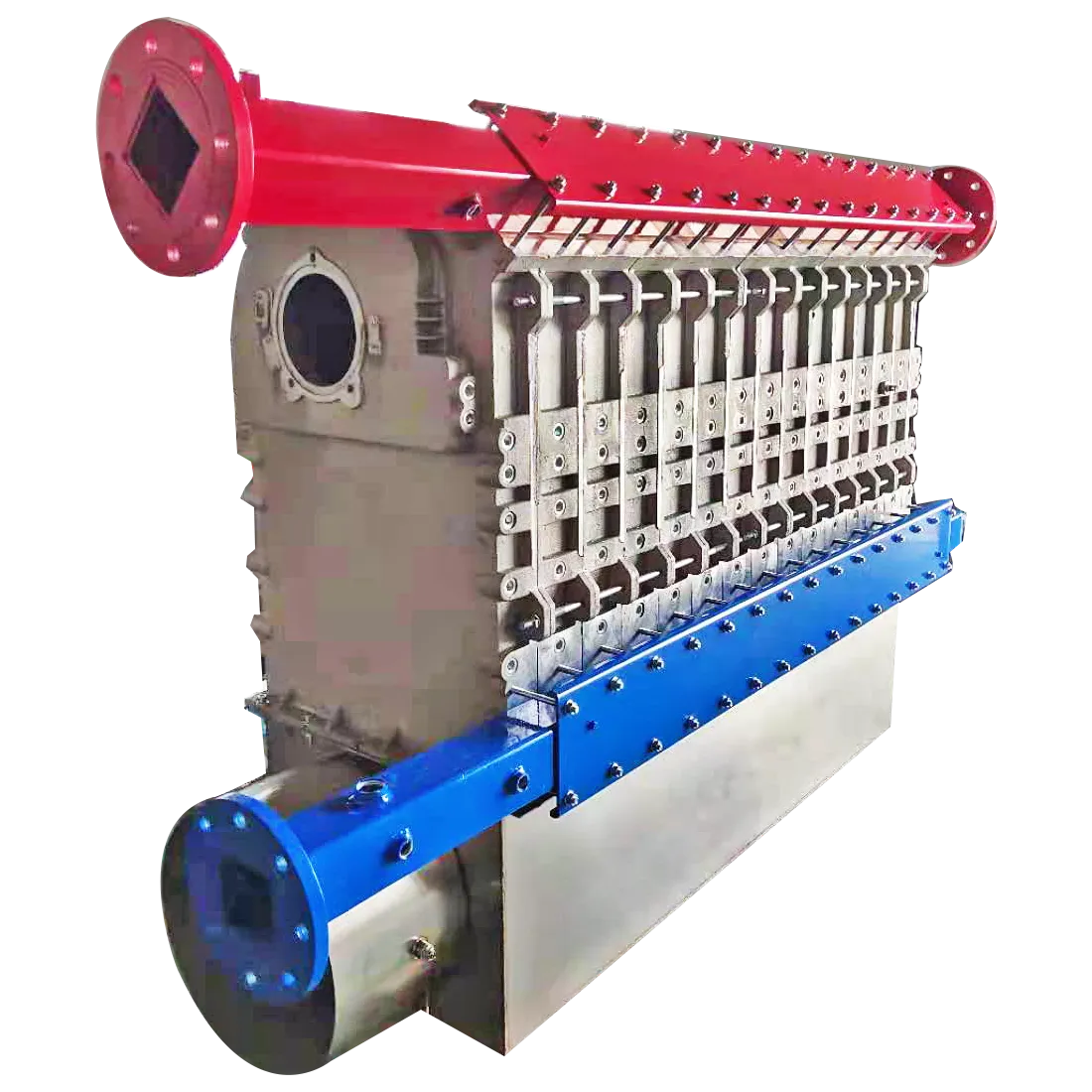

Cast Aluminum Heat Exchanger Design for Home Heating Boiler Applications

The Advantages of Cast Silicon Aluminum Heat Exchangers for Domestic Heating Boilers

In recent years, the quest for energy-efficient and environmentally friendly heating systems has led to significant innovations in boiler technology. Among the most promising developments is the use of cast silicon aluminum heat exchangers. These components play a crucial role in domestic heating boilers, enhancing performance, efficiency, and longevity. This article delves into the benefits and applications of cast silicon aluminum heat exchangers in residential heating solutions.

Understanding Heat Exchangers

Heat exchangers are integral components in heating systems, facilitating the transfer of heat from the combustion process to the water or air used for heating domestic spaces. Traditionally, heat exchangers have been made from materials like copper, stainless steel, and cast iron. However, the advent of cast silicon aluminum presents a new frontier in heat exchanger technology.

The Composition and Properties of Cast Silicon Aluminum

Cast silicon aluminum is an alloy that combines aluminum with a small percentage of silicon. This composition lends the material unique properties, such as excellent thermal conductivity, corrosion resistance, and low density. The presence of silicon enhances the fluidity of the molten aluminum during the casting process, making it easier to create intricate designs that improve heat transfer efficiency.

One of the standout features of cast silicon aluminum is its resistance to oxidation and corrosion, especially in high-temperature environments. This durability ensures that heat exchangers maintain their functionality over long periods, reducing the need for frequent replacements or maintenance.

Efficiency and Performance Advantages

The primary function of a heat exchanger is to transfer heat effectively. Cast silicon aluminum heat exchangers boast improved thermal efficiency compared to traditional materials. Their high thermal conductivity allows for quicker heat transfer from the combustion gases to the heating medium. This leads to faster heating times, ensuring that homes reach desired temperatures more quickly, resulting in enhanced comfort for residents.

cast silicon aluminum heat exchanger for domestic heating boiler

Moreover, the lightweight nature of cast silicon aluminum makes it easier to manufacture compact heat exchanger designs. This versatility allows for more flexible installation options, accommodating various boiler configurations without compromising performance. The combination of improved efficiency and reduced installation complexity makes cast silicon aluminum heat exchangers an attractive option for manufacturers and consumers alike.

Environmental Impact

Environmental considerations are paramount in modern heating solutions. The use of cast silicon aluminum not only improves efficiency but also contributes to lower energy consumption. With better heat transfer capabilities, boilers equipped with these heat exchangers can operate at lower temperatures and pressures, reducing the overall carbon footprint of domestic heating systems.

Additionally, as energy prices continue to fluctuate, the need for cost-effective solutions is more critical than ever. By improving the efficiency of heating systems, cast silicon aluminum heat exchangers can lead to significant savings on energy bills, benefiting both the consumer and the environment.

Challenges and Future Directions

While the advantages of cast silicon aluminum heat exchangers are clear, some challenges remain. The production process for these materials requires careful control to ensure consistency and performance. Additionally, the industry must continue to develop cost-effective manufacturing techniques to make cast silicon aluminum heat exchangers accessible to a broader market.

However, ongoing research and advancement in materials science are paving the way for further improvements. Innovations in casting techniques, alloy compositions, and surface treatments could enhance the properties of cast silicon aluminum even further, making it the material of choice for future heating applications.

Conclusion

In summary, cast silicon aluminum heat exchangers represent a significant advancement in domestic heating technology. Their superior thermal efficiency, durability, and environmental benefits make them an excellent choice for modern heating systems. As the demand for efficient and sustainable heating solutions grows, cast silicon aluminum will likely play an increasingly vital role in shaping the future of residential heating, providing comfort while minimizing environmental impact. The continuous innovation in this field promises a brighter, more efficient future for domestic heating systems worldwide.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025