Sult . 04, 2024 13:07 Back to list

aluminium casting equipment

Overview of Aluminium Casting Equipment

Aluminium casting is a crucial process in various manufacturing industries, allowing for the production of complex shapes and high-quality components. To achieve optimal results in aluminium casting, the right equipment is essential. This article provides an overview of key types of aluminium casting equipment and their significance in the casting process.

One of the most fundamental pieces of equipment in aluminium casting is the melting furnace. These furnaces are designed to reach the high temperatures necessary to melt aluminium alloys effectively. There are several types of furnaces used in the industry, including gas-fired, electric, and induction furnaces. Each type has its advantages, with induction furnaces often favored for their energy efficiency and precise temperature control, ensuring a homogeneous melt.

Once the aluminium is melted, it needs to be poured into a mold. This is where pouring equipment comes into play. Ladles are commonly used to transport and pour molten aluminium into the molds. Modern ladles come equipped with features like pouring spouts and tilting mechanisms that enhance precision and reduce the risk of spillage, thereby improving safety and efficiency during the casting process.

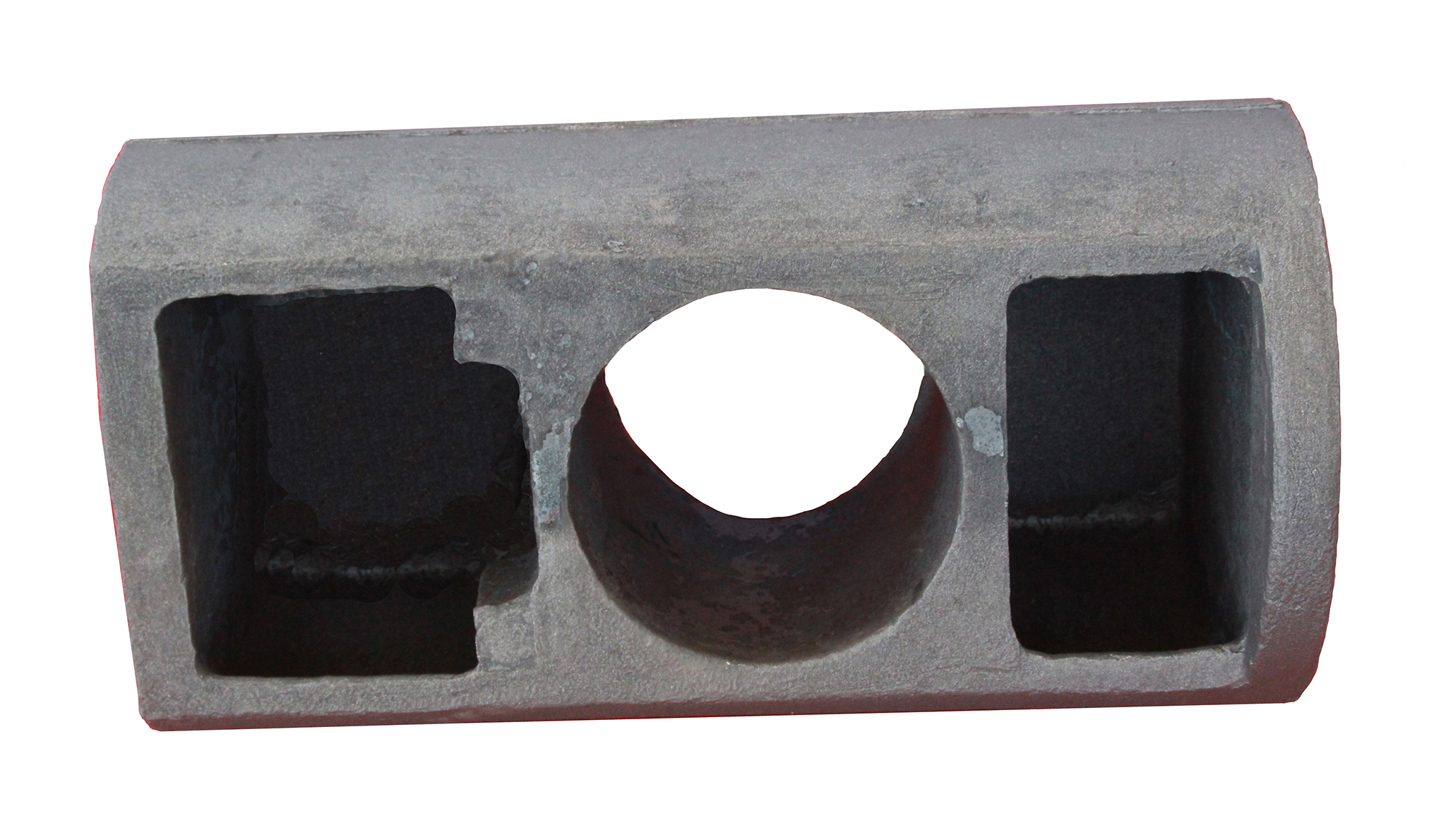

Molding equipment is another critical aspect of aluminium casting. Depending on the casting method, various types of molds are used, such as sand molds, permanent molds, and investment molds. Each type offers unique benefits—sand molds are versatile and cost-effective, while permanent molds are ideal for high-volume production due to their durability and reusability.

aluminium casting equipment

In addition to these primary equipment types, other ancillary equipment plays a vital role in the aluminium casting process. Cooling systems are essential for managing the temperature of the casting environment and ensuring that components solidify properly. Additionally, shot blasting machines are often used post-casting to clean the finished products, removing any residual mold material and improving surface finish.

Automation is progressively transforming aluminium casting operations

. Robotic systems and automated ladles enhance the precision and speed of pouring processes, reducing human error and improving overall productivity.Finally, it's important to note that regular maintenance of casting equipment is crucial to ensure optimal performance and longevity. Keeping furnace linings, ladles, and molds in good condition minimizes defects in the final products and maintains production efficiency.

In conclusion, aluminium casting equipment comprises a range of specialized tools that work together to produce high-quality components. From melting furnaces to advanced molding techniques, understanding the roles of these various pieces of equipment is vital for manufacturers aiming to achieve excellence in aluminium casting. With continued advancements in technology, the future of aluminium casting equipment looks promising, allowing for even greater innovation and efficiency in the industry.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025