Samh . 13, 2024 07:13 Back to list

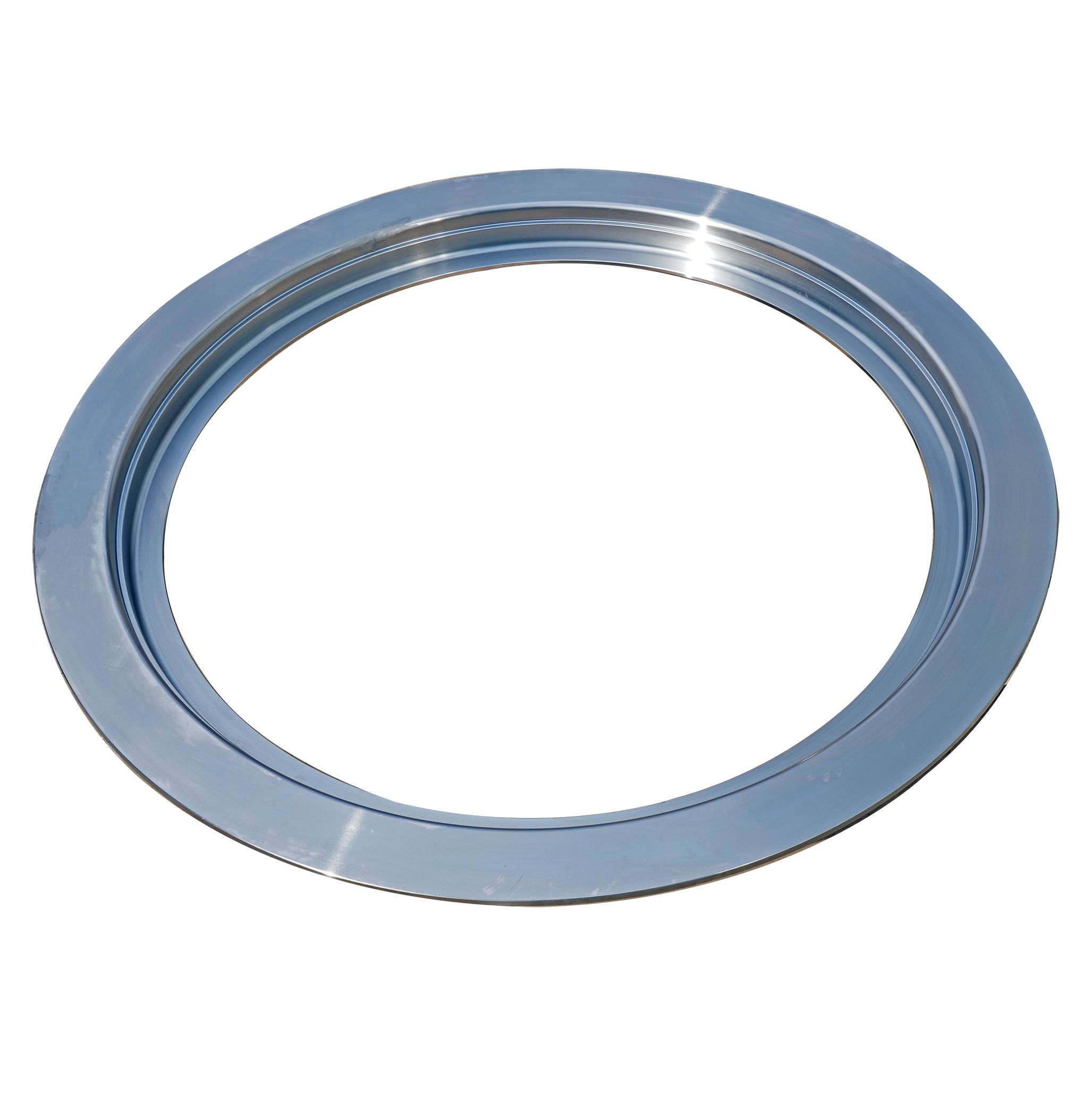

custom heating exchanger

Custom Heating Exchangers Enhancing Efficiency in Thermal Management

In today's fast-paced industrial environment, the need for efficient thermal management systems has never been greater. One of the key components in achieving this is the heating exchanger. Custom heating exchangers have emerged as vital elements in various applications, catering to the unique requirements of different industries. This article delves into the significance of custom heating exchangers, their benefits, and their applications.

Understanding Heating Exchangers

Heating exchangers are devices that facilitate the transfer of heat between two or more fluids without allowing them to mix. They are widely used in processes that require heating, cooling, or energy recovery. The efficiency of these systems directly impacts operational costs and productivity, making the choice of an appropriate heating exchanger crucial.

Traditional heating exchangers come in standard designs, which may not suit every application. This is where custom heating exchangers come into play, providing tailor-made solutions that optimize thermal efficiency and performance.

Benefits of Custom Heating Exchangers

1. Tailored Design Custom heating exchangers are designed to meet the specific needs of a project or process. Factors like fluid type, temperature, pressure, and flow rate are taken into account. This tailored approach ensures maximum efficiency and can lead to substantial energy savings.

2. Increased Efficiency By optimizing dimensions and materials, custom heating exchangers can enhance heat transfer capabilities. This results in quicker temperature adjustments and reduced energy consumption, ultimately lowering operational costs.

custom heating exchanger

3. Space Optimization In many industrial settings, space is a premium. Custom heating exchangers can be designed to fit specific spatial constraints, enabling the integration of efficient thermal management systems even in compact environments.

4. Customization of Materials Different applications require different materials for safety and efficiency. Custom heating exchangers can be built with materials that withstand corrosive substances, high temperatures, or extreme pressure, tailored to the unique challenges of each environment.

5. Enhanced Durability and Lifespan With a custom design, these exchangers can endure the specific stresses of their environment, which increases their durability and lifespan. This translates to lower maintenance costs and extended operational intervals.

Applications Across Industries

Custom heating exchangers find application in various sectors, including

- Chemical Processing They play a pivotal role in maintaining precise temperatures during chemical reactions. - Food and Beverage Essential for pasteurization and heating, ensuring product safety and quality. - Pharmaceuticals Used in processes requiring stringent temperature control to maintain the integrity of sensitive compounds. - HVAC Systems Custom solutions improve energy efficiency, providing comfortable environments while minimizing energy costs.

Conclusion

In summary, custom heating exchangers are essential for efficient thermal management across multiple industries. Their tailored design and enhanced capabilities offer significant advantages over traditional models, making them a worthy investment for organizations aiming to improve operational efficiency and reduce costs. As industries evolve and the demand for energy-efficient solutions increases, the importance of custom heating exchangers will only continue to grow, solidifying their role in sustainable industrial practices.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025