Dùbh . 03, 2024 14:48 Back to list

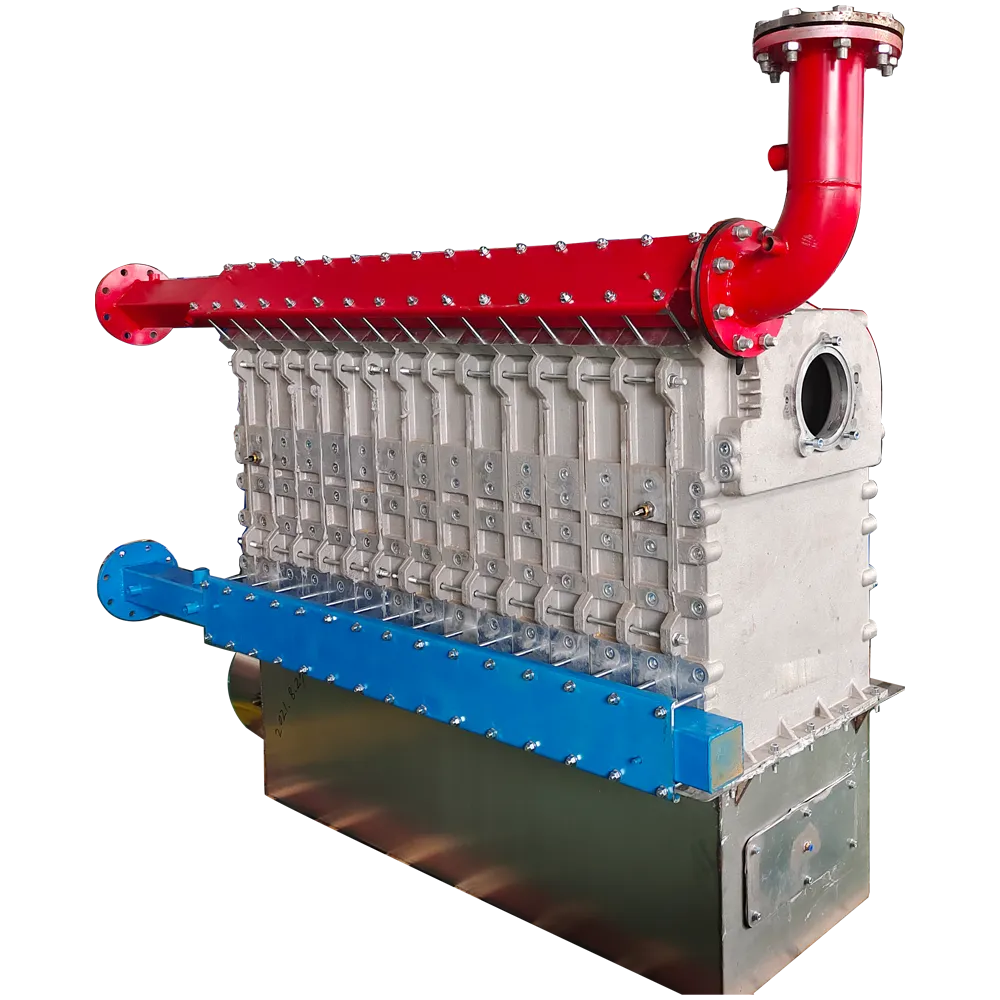

investment casting parts exporter

Investment Casting Parts Exporter A Gateway to Precision and Quality

Investment casting, known for its ability to produce intricate and high-precision metal parts, has emerged as a critical method in various industries such as aerospace, automotive, and medical. As the global demand for customized, high-quality components grows, the role of investment casting parts exporters becomes increasingly significant. This article explores the importance, methodology, and benefits of working with investment casting parts exporters.

The Investment Casting Process

Investment casting, also called lost-wax casting, involves several stages. Initially, a wax pattern of the desired component is created. This pattern is then coated with a ceramic shell, which hardens to form a mold. Once the shell is set, the wax is melted away, leaving a hollow cavity in the shape of the desired part. Molten metal is then poured into this cavity, and after cooling, the ceramic shell is removed to reveal the finished product. This process allows for the production of parts with complex geometries and excellent surface finishes that are often impossible to achieve through traditional machining methods.

The Role of Investment Casting Parts Exporters

Investment casting parts exporters serve as a vital link between manufacturers and global markets. By working with various foundries and suppliers, these exporters can offer a wide range of casting materials, including aluminum, steel, copper, and more. They play a crucial role in ensuring quality control, timely delivery, and compliance with international standards, thereby facilitating businesses' expansion into international markets.

One of the key advantages of partnering with an investment casting parts exporter is access to advanced technology and resources. Exporters often collaborate with state-of-the-art foundries that employ the latest casting techniques and equipment, ensuring that customers receive high-quality products that meet their specifications. This access is essential for businesses looking to maintain a competitive edge in an increasingly globalized economy.

Benefits of Investment Casting

investment casting parts exporter

Investment casting offers numerous advantages, making it an attractive option for many manufacturers. One of the primary benefits is the ability to produce parts with high dimensional accuracy and a superior surface finish. This precision reduces the need for extensive post-casting machining, which can save time and costs while minimizing material waste.

Furthermore, investment casting allows for the production of complex shapes that would be challenging or impossible to achieve using traditional methods. This flexibility enables designers and engineers to innovate and create more efficient parts, ultimately leading to better performance and reliability in applications.

Cost-effectiveness is another significant advantage. Although the initial tooling and setup costs for investment casting can be higher compared to other manufacturing methods, the overall savings in production volume, material waste, and post-processing often outweigh these costs. Additionally, the durability of investment cast parts can lead to a longer lifespan, which further enhances their cost-effectiveness.

Global Market Trends

In recent years, the investment casting market has expanded, driven by the growth of sectors such as aerospace and automotive, where lightweight and high-strength materials are in demand. Emerging economies have also seen a surge in investment casting activities, as local manufacturers strive to reduce production costs while improving quality.

Investment casting parts exporters have been quick to adapt to these market trends by diversifying their offerings and expanding their supply chains. By sourcing materials and services from various regions, they can provide competitive pricing and meet the evolving needs of their customers.

Conclusion

The role of investment casting parts exporters is integral to the success of businesses seeking precision-engineered components. By leveraging advanced technology, quality control, and global supply chains, these exporters enable manufacturers to access the best casting solutions available. As industries continue to innovate and demand for high-quality components rises, investment casting will undoubtedly play a pivotal role in shaping the future of manufacturing. In this framework, investment casting parts exporters not only facilitate access to quality products but also contribute significantly to the growth and sustainability of the global economy.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025