Out . 31, 2024 10:03 Back to list

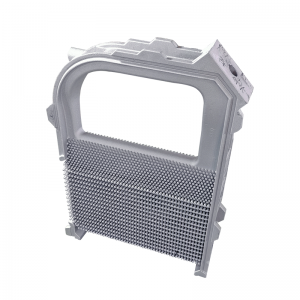

carbon steel casting exporter

The Rise of Carbon Steel Casting Exporters

In the world of manufacturing, carbon steel is a pivotal material known for its durability, strength, and versatility. It has found applications in numerous fields, including automotive, construction, and machinery. As industries continue to evolve, the demand for high-quality carbon steel castings has surged globally, giving rise to an increasing number of carbon steel casting exporters.

Understanding Carbon Steel Casting

Carbon steel casting involves the process of creating components by pouring molten carbon steel into a mold. The resulting products range from simple shapes to intricate designs, based on the requirements of various industries. The unique properties of carbon steel, which include excellent mechanical strength, wear resistance, and the ability to withstand high temperatures, make it a favored choice for manufacturers. Additionally, carbon steel can be easily alloyed with other elements, allowing for further enhancements in its properties.

Global Market Dynamics

The global market for carbon steel castings is witnessing robust growth due to extensive industrialization, especially in emerging economies. Countries such as India, China, and Brazil have experienced substantial growth in their manufacturing sectors, leading to a higher demand for carbon steel castings. Moreover, developed nations are also investing in advanced manufacturing technologies, which increase the need for high-quality cast components.

The rise of technology-driven processes, such as 3D printing and automated casting, has also played a role in the growth of carbon steel casting exporters. These advancements allow for greater precision and efficiency, enabling exporters to meet the rigorous demands of their clients.

Advantages of Importing Carbon Steel Castings

carbon steel casting exporter

For companies looking to source carbon steel castings, international exporters offer numerous advantages. First and foremost, exporters often provide access to state-of-the-art manufacturing facilities equipped with the latest technologies. This means that companies can obtain high-quality components at competitive prices.

Additionally, global sourcing allows businesses to diversify their supply chains, reducing dependency on local suppliers. This can lead to improved negotiation power and greater flexibility in meeting production demands. Furthermore, international exporters may provide a wider variety of products, catering to specialized requirements that local suppliers might not meet.

Quality Assurance and Compliance

One critical aspect of importing carbon steel castings is the need for quality assurance and compliance with international standards. Reputable exporters adhere to stringent quality control measures to ensure the reliability and safety of their products. Certifications such as ISO 9001 and compliance with environmental standards are often prerequisites for successful exporters, as clients prioritize long-term partnerships with reliable suppliers.

The Future of Carbon Steel Casting Exports

Looking ahead, the future of carbon steel casting exporters is promising. As industries increasingly focus on sustainability, there will be a push for more environmentally friendly manufacturing processes. Exporters that can innovate and adapt to these trends will likely maintain a competitive edge in the market.

Moreover, the continuing growth of sectors such as renewable energy, electric vehicles, and advanced machinery will further spur the demand for carbon steel castings. As industries evolve, so too will the needs of manufacturers, creating new opportunities for exporters that can deliver high-quality, efficient solutions.

In conclusion, the rise of carbon steel casting exporters represents a crucial element in the interconnected global manufacturing landscape. By understanding market dynamics and focusing on quality and innovation, these exporters are well-positioned to thrive in an increasingly competitive environment. As industries continue to grow and change, the role of carbon steel castings will undoubtedly remain significant, both domestically and internationally.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025