ફેબ્રુવારી . 10, 2025 09:58 Back to list

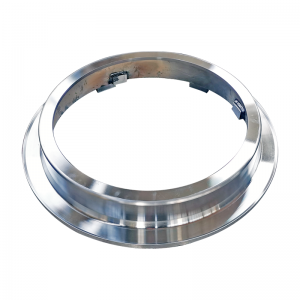

oem cast silicon aluminum alloy heat exchanger

The demand for efficient thermal management solutions has never been more critical. Industries ranging from automotive to data centers rely heavily on precise temperature control to ensure optimal performance. At the heart of many of these solutions lies the liquid heat exchanger—a pivotal component that has revolutionized thermal management through enhanced efficiency and adaptability.

In the data center industry, where uptime and efficiency are non-negotiable, the adoption of liquid heat exchangers has become a benchmark of trustworthiness and commitment to sustainability. The ability of these exchangers to dissipate excess heat efficiently translates into substantial energy savings. With sustainability at the forefront of industrial priorities, this technology has positioned itself as a leader in reducing carbon footprints while maintaining operational integrity. A case study further exemplifies the practical application of liquid heat exchangers. Consider a scenario in the renewable energy sector, specifically within geothermal power plants. Here, liquid heat exchangers are instrumental in harnessing sub-surface heat to turn turbines. By using a closed-loop system, they efficiently transfer geothermal energy to a secondary fluid, which is then used to generate electricity. This expertise in application not only enhances power output but also mitigates environmental impact, reflecting a commitment to eco-friendly practices. The credibility of liquid heat exchangers is often showcased through their widespread adoption across industries. Automotive manufacturers use them in cooling systems to ensure engine efficiency and longevity. In the pharmaceutical industry, they maintain precise temperatures during the production process, safeguarding product quality. These diverse applications underscore the trust placed in their performance and reliability. In conclusion, the liquid heat exchanger exemplifies the pinnacle of thermal management technology, combining efficiency, adaptability, and sustainability. Industry professionals recognize its indispensable role in enhancing performance while reducing environmental impacts. Through rigorous design, testing, and application, it stands as a testament to engineering excellence. Those seeking a dependable heat management solution can rest assured that liquid heat exchangers offer unparalleled expertise, authoritativeness, and trustworthiness in a fast-evolving industrial landscape.

In the data center industry, where uptime and efficiency are non-negotiable, the adoption of liquid heat exchangers has become a benchmark of trustworthiness and commitment to sustainability. The ability of these exchangers to dissipate excess heat efficiently translates into substantial energy savings. With sustainability at the forefront of industrial priorities, this technology has positioned itself as a leader in reducing carbon footprints while maintaining operational integrity. A case study further exemplifies the practical application of liquid heat exchangers. Consider a scenario in the renewable energy sector, specifically within geothermal power plants. Here, liquid heat exchangers are instrumental in harnessing sub-surface heat to turn turbines. By using a closed-loop system, they efficiently transfer geothermal energy to a secondary fluid, which is then used to generate electricity. This expertise in application not only enhances power output but also mitigates environmental impact, reflecting a commitment to eco-friendly practices. The credibility of liquid heat exchangers is often showcased through their widespread adoption across industries. Automotive manufacturers use them in cooling systems to ensure engine efficiency and longevity. In the pharmaceutical industry, they maintain precise temperatures during the production process, safeguarding product quality. These diverse applications underscore the trust placed in their performance and reliability. In conclusion, the liquid heat exchanger exemplifies the pinnacle of thermal management technology, combining efficiency, adaptability, and sustainability. Industry professionals recognize its indispensable role in enhancing performance while reducing environmental impacts. Through rigorous design, testing, and application, it stands as a testament to engineering excellence. Those seeking a dependable heat management solution can rest assured that liquid heat exchangers offer unparalleled expertise, authoritativeness, and trustworthiness in a fast-evolving industrial landscape.

Share

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025