אוק . 14, 2024 12:30 Back to list

cast steel pipe mould bottom ring factories

The Importance of Cast Steel Pipe Mould Bottom Ring Factories

In the manufacturing industry, the integrity and durability of components are paramount, especially in sectors that rely on heavy machinery and infrastructure. One such critical component is the cast steel pipe mould bottom ring. Factories specializing in the production of these components play a vital role in ensuring that various industries, from construction to oil and gas, maintain high standards of quality and safety.

Understanding Cast Steel Pipe Mould Bottom Rings

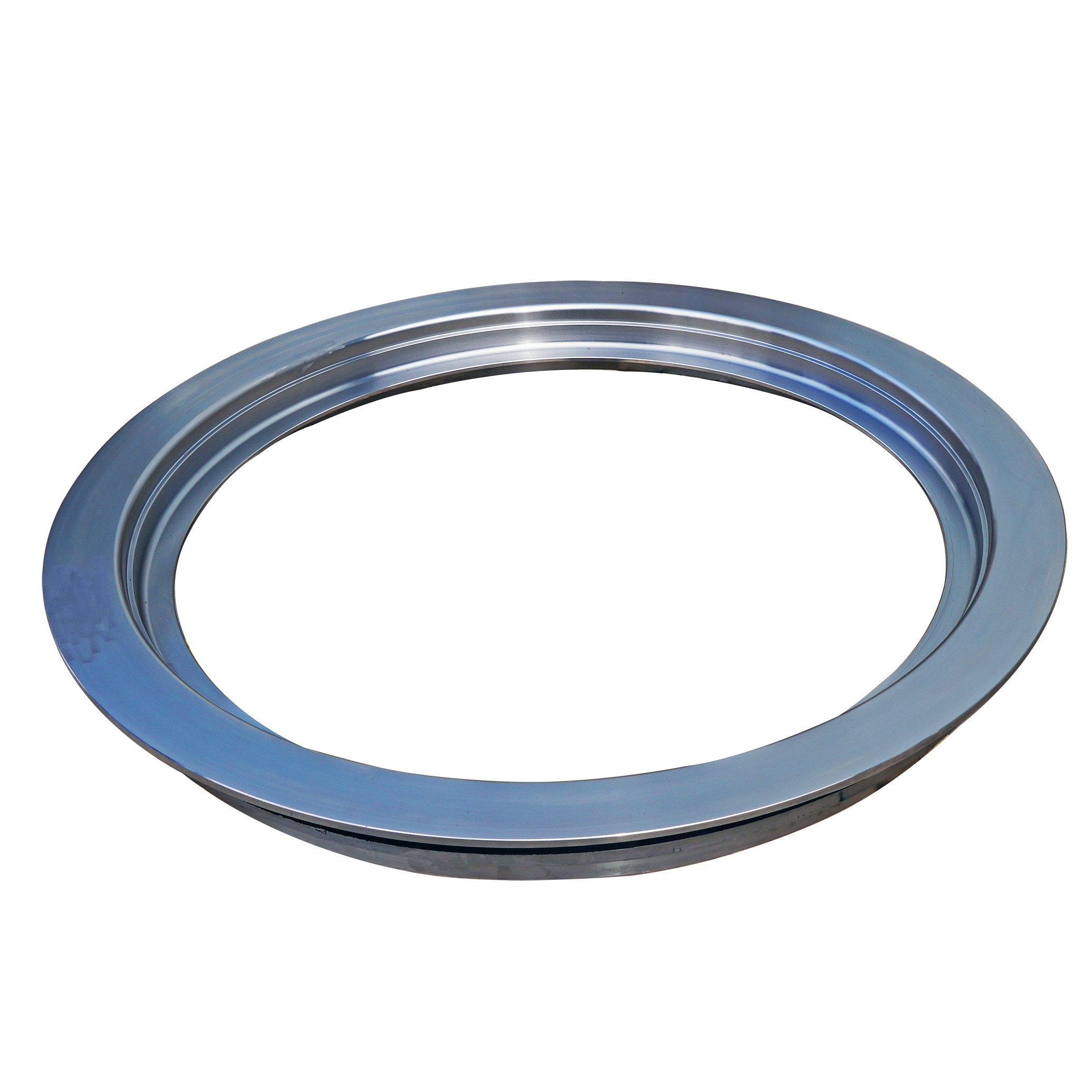

Cast steel pipe mould bottom rings are essential components used in the manufacturing process of concrete pipes. These rings serve multiple purposes they provide structural support, define the shape of the pipe, and contribute to the efficiency of the casting process. Made from high-quality cast steel, these rings are designed to withstand extreme pressures and temperature variations, ensuring the longevity and reliability of the pipes they help create.

The Manufacturing Process

The production of cast steel pipe mould bottom rings involves several key stages, including design, casting, machining, and quality assurance

. Factories usually begin with advanced computer-aided design (CAD) tools to create precise specifications that meet industry standards. After the design phase, the casting process takes place, where molten steel is poured into molds to create the bottom rings.Once the casting is complete, the rings go through a machining process to achieve the necessary dimensions and finish. This may include milling, grinding, and drilling, ensuring that every part meets strict tolerances. The final stage involves rigorous quality control measures, where each component is tested for strength and durability before being dispatched for use in various applications.

cast steel pipe mould bottom ring factories

Innovations and Advancements

In recent years, advancements in technology have significantly improved the production processes in factories that manufacture cast steel pipe mould bottom rings. The integration of automation and robotics has increased efficiency and precision, reducing production times while enhancing product quality. Moreover, the use of recycled materials in the casting process has become more prevalent, aligning with global sustainability efforts.

Global Demand and Market Trends

The demand for cast steel pipe mould bottom rings has risen steadily in line with the growth of infrastructure projects worldwide. As urbanization intensifies, the need for reliable water transportation systems and sewage infrastructure becomes increasingly critical. This has led to a burgeoning market for high-quality cast steel components.

Furthermore, factories are not only focusing on domestic markets; many are expanding their reach internationally. By ensuring compliance with international standards and certifications, these factories can compete effectively in a global marketplace, catering to various industries needing durable and efficient solutions.

Conclusion

In conclusion, the importance of cast steel pipe mould bottom ring factories cannot be understated. They play a crucial role in the production of essential components that uphold the integrity of infrastructure worldwide. As technology evolves and market demands shift, these factories will continue to innovate, ensuring that they meet the needs of a rapidly changing industrial landscape. The ongoing investment in quality, efficiency, and sustainability will ensure that they remain at the forefront of the manufacturing sector for years to come.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025