नवम्बर . 11, 2024 16:25 Back to list

cast iron pipe mold bottom ring factory

The Importance of Cast Iron Pipe Mold Bottom Rings in Manufacturing

In the realm of manufacturing, particularly in the production of piping systems, various components play crucial roles in ensuring the durability and efficiency of the final product. One such component that deserves significant attention is the cast iron pipe mold bottom ring. This essential part not only contributes to the structural integrity of pipes but also influences the manufacturing process itself.

Understanding Cast Iron Pipe Mold Bottom Rings

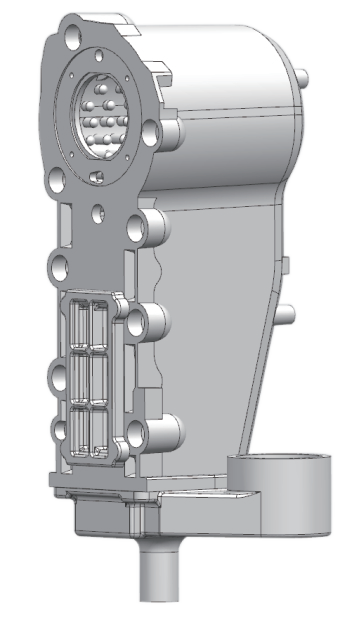

Cast iron pipe mold bottom rings are specialized components used in the casting of pipes. They serve as the foundation for the mold structure, providing the stability needed during the casting process. The design and quality of these rings can significantly impact the efficiency of production, ensuring that pipes are formed with precision and consistency.

The bottom ring typically acts as a support system that holds the molten iron during the casting process, allowing it to cool and solidify into the desired pipe shape. Made from cast iron, these rings exhibit excellent strength and durability, essential characteristics for withstanding the high temperatures associated with the casting of iron pipes.

The Manufacturing Process

The production of cast iron pipe mold bottom rings involves several key steps, beginning with the selection of high-quality materials. The manufacturing process usually comprises the following stages

1. Material Selection The choice of cast iron as the primary material is fundamental. This material is known for its excellent casting properties, ability to resist deformation under high temperatures, and longevity.

2. Mold Design Engineers devise precise mold designs to create bottom rings that meet specific dimensional and functional requirements. The design process often involves advanced computer-aided design (CAD) software to ensure accuracy.

3. Casting The chosen cast iron is melted and poured into the molds. Once cooled, the result is a solidified bottom ring, which is then removed from the mold. The casting process demands meticulous temperature control to achieve optimal properties in the final product.

cast iron pipe mold bottom ring factory

4. Finishing Treatments After casting, the rings undergo various finishing treatments, such as sanding or machining, to achieve a smooth surface and precise dimensions. Quality control during this stage is critical to meet industry standards.

5. Inspection and Testing Finally, each bottom ring is subjected to rigorous inspection and testing to verify its mechanical properties and dimensional accuracy. Ensuring that these components meet industry specifications is vital for maintaining the quality of the pipes they will help shape.

Applications in the Industry

Cast iron pipe mold bottom rings are widely used in the production of various types of pipes, including those utilized in water supply, sewage systems, and industrial applications. Their robustness and reliability ensure that the pipes produced can withstand internal pressures and environmental factors, thereby extending their lifespan and reducing maintenance costs.

Furthermore, the uniformity achieved through high-quality casting processes translates to enhanced performance. Pipes manufactured with precision cast rings exhibit fewer leaks and failures, which is critical for infrastructure projects where reliability is paramount.

Sustainability Considerations

In recent years, the focus on sustainability within manufacturing has grown significantly. The production of cast iron pipe mold bottom rings can align with these sustainability goals through practices such as recycling scrap iron and optimizing energy use during the casting process. By implementing eco-friendly practices, factories can minimize their environmental footprint while still producing high-quality components.

Conclusion

In summary, cast iron pipe mold bottom rings are a vital component in the manufacturing of pipes, significantly influencing their structural integrity and overall quality. As industries continue to seek efficiency and sustainability, the role of these rings becomes even more critical. Investing in advanced manufacturing techniques and high-quality materials will not only improve product outcomes but also contribute to a more sustainable future in pipe manufacturing. Whether in urban infrastructure or industrial applications, the importance of these seemingly small components cannot be overstated, as they are truly the unsung heroes of the piping world.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025