नवम्बर . 26, 2024 21:15 Back to list

Exporters of Concrete Pipe Moulds and Bottom Rings for FRC Applications

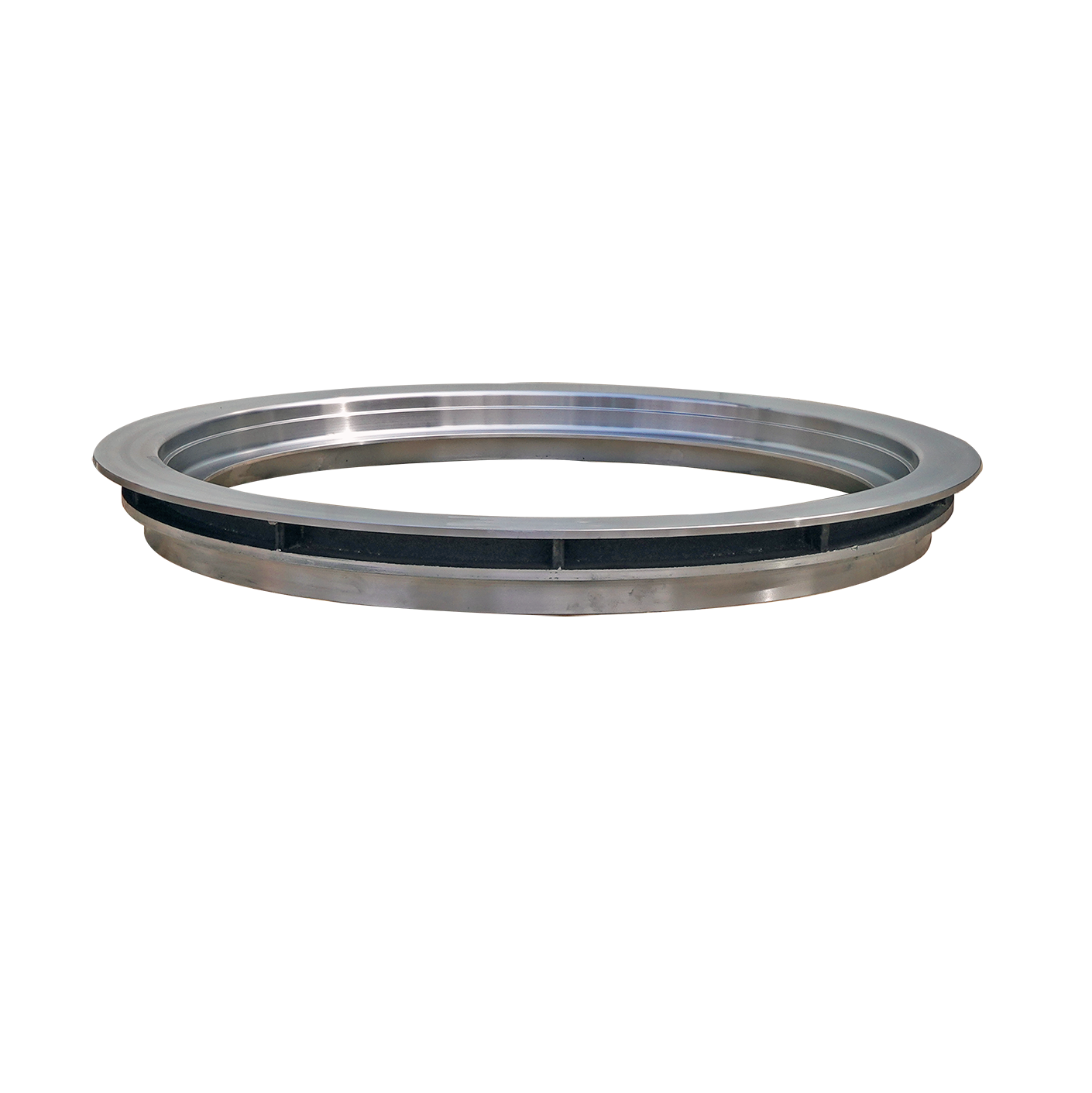

The Significance of FRC Concrete Pipe Mould Bottom Rings in Modern Construction

In the ever-evolving landscape of the construction industry, the demand for durable and efficient building materials continues to rise. Among these materials, FRC (Fiber-Reinforced Concrete) has emerged as a game-changer, especially in the production of concrete pipes. One critical component in the manufacture of these concrete pipes is the bottom ring of the FRC concrete pipe mould. This article explores the significance of FRC concrete pipe mould bottom rings, the advantages they offer, and their relevance to exporters in the global marketplace.

Understanding FRC and its Importance in Concrete Pipes

Fiber-Reinforced Concrete is a composite material that integrates fibrous materials into the concrete mix to enhance its structural integrity. This reinforcement can be in the form of steel fibers, glass fibers, or synthetic fibers, which improve the tensile strength, ductility, and durability of the concrete. FRC is especially advantageous in applications requiring high load-bearing capabilities, such as underground drainage systems and stormwater management.

Concrete pipes made from FRC are increasingly favored for their ability to withstand heavy loads and resist cracking, making them a preferred choice for various civil engineering projects. As urbanization accelerates and infrastructure projects grow in complexity, the need for reliable and robust drainage solutions becomes paramount.

The Role of Bottom Rings in Concrete Pipe Manufacturing

The bottom ring of the FRC concrete pipe mould plays a crucial role in shaping the final product. It is designed to ensure proper alignment, support, and stability during the pouring and curing process of the concrete mixture. The bottom ring's specification often varies based on the diameter and intended use of the concrete pipe.

High-quality bottom rings contribute to the efficiency of the manufacturing process. They enable manufacturers to produce consistent and reliable pipes with precise dimensions, which are essential for their performance in real-world applications. Without proper moulding, issues such as uneven surfaces, dimensional inaccuracies, and structural weaknesses may arise, leading to costly repairs and project delays.

Advantages of FRC Concrete Pipe Mould Bottom Rings

frc concrete pipe mould bottom ring exporters

1. Durability FRC concrete pipe mould bottom rings are designed to withstand the rigors of the moulding process. They are resistant to wear and tear, ensuring that they maintain their shape and function over numerous production cycles.

2. Cost-Effectiveness By enhancing the quality of concrete pipes, these bottom rings help prevent material wastage and reduce production costs. The precision they offer leads to fewer errors in the final product, ultimately saving time and resources.

3. Versatility Manufacturers can create bottom rings tailored to various applications and specifications. This adaptability allows for a broader range of product offerings, catering to various market needs.

4. Improved Structural Performance Bottom rings facilitate the creation of pipes with enhanced structural performance attributes. Pipes produced using FRC are less prone to failure under stress, making them ideal for high-demand applications.

The Export Market for FRC Concrete Pipe Mould Bottom Rings

As the demand for robust infrastructure grows globally, so does the market for FRC concrete pipe mould bottom rings. Exporters play a vital role in meeting this demand, providing high-quality moulds to manufacturers across different countries.

Exporters must focus not only on the quality but also on the innovation of their products. Investing in research and development to enhance the design and functionality of bottom rings ensures they remain competitive in a crowded market. Furthermore, understanding international quality standards and regulations is crucial for exporters to succeed in diverse markets.

In conclusion, the significance of FRC concrete pipe mould bottom rings cannot be overstated. As the construction industry continues to evolve, the necessity for durable and efficient building materials like FRC will only increase. Exporters of these bottom rings are positioned at a pivotal point in the supply chain, enabling the global construction industry to achieve its goals of sustainability, reliability, and efficiency. By prioritizing quality and innovation, these exporters can contribute to the creation of infrastructure that meets the challenges of today and tomorrow.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025